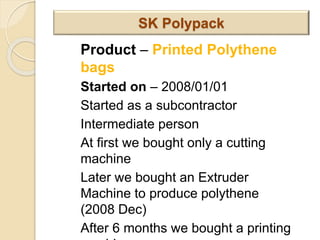

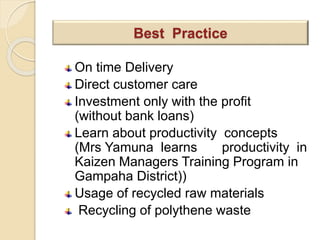

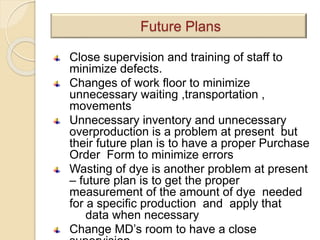

Sisira Kumara is the Managing Director of SK POLYPACK in Sri Lanka, which produces printed polythene bags. The company started in 2008 as a subcontractor with only a cutting machine. In 2008, they bought an extruder machine to produce polythene, and after 6 months bought a printing machine. Their growth was slow with no guidance. In 2010, they joined the Kaizen Entrepreneurs Project and learned productivity concepts from the National Productivity Secretariat. This helped change employee attitudes, build confidence, reduce costs and increase revenue. Employee numbers grew from 2 to 15 from 2009-2014 as turnover increased from 0.08 million to 3.4 million rupees. Future plans include close