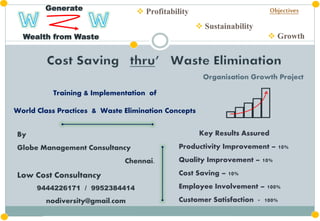

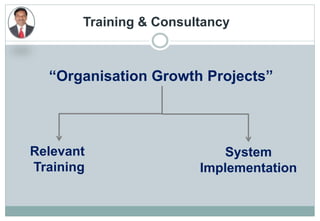

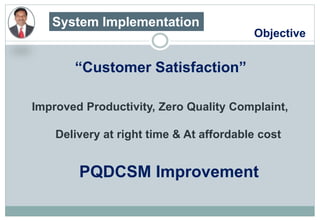

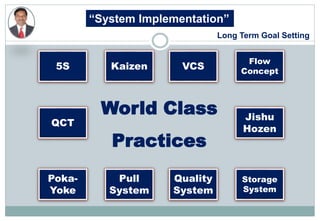

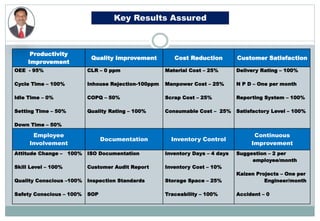

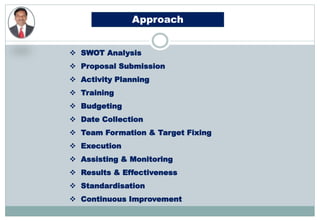

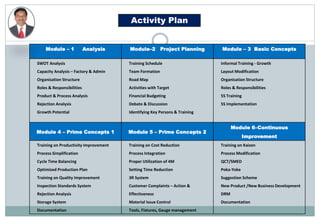

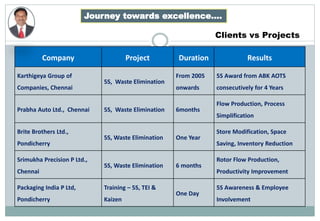

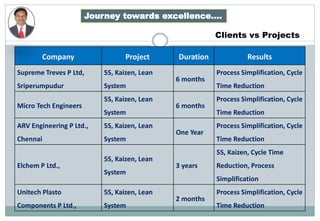

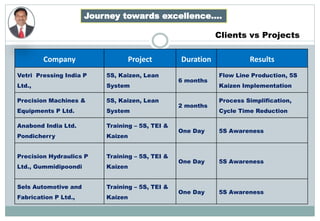

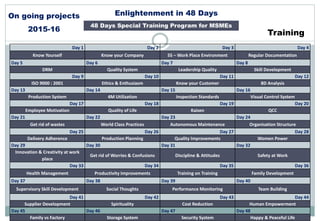

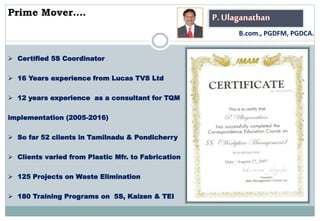

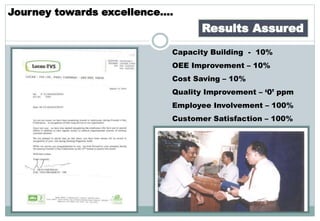

This document provides information about training and consultancy services offered by Globe Management Consultancy to help organizations improve productivity, quality, costs, and employee and customer satisfaction through implementing world-class practices and eliminating waste. The consultancy focuses on areas like 5S, kaizen, lean systems, quality systems and aims to improve key metrics like OEE, cycle time, downtime and inspection standards. A 48-day special training program for MSMEs is also described covering various topics. Case studies of projects conducted for various companies are mentioned to demonstrate experience and achieved results.