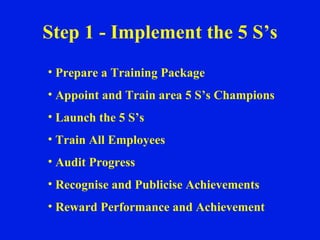

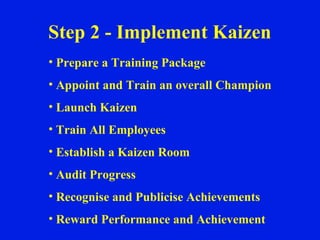

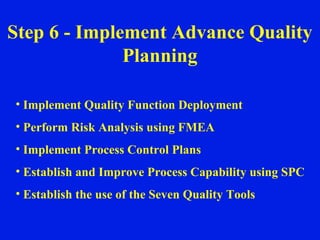

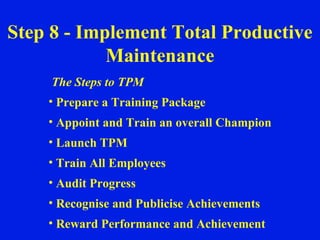

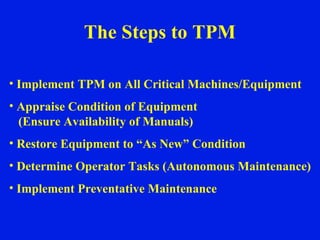

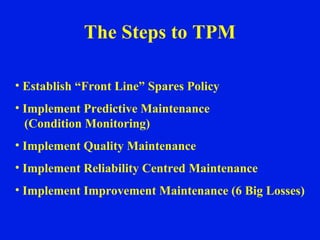

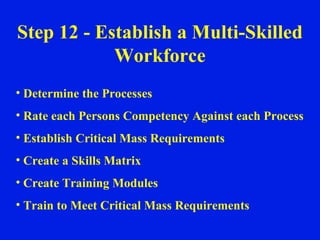

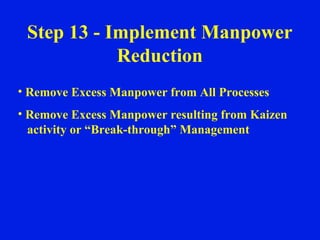

The document outlines 13 steps to improve manufacturing systems through lean principles. The steps include implementing 5S, kaizen, one-piece flow, kanban, quality planning, visual controls, total productive maintenance, jidoka, standard work, leveling, a multi-skilled workforce, manpower reduction, and using success factors like coaching, KPIs, and rewards.