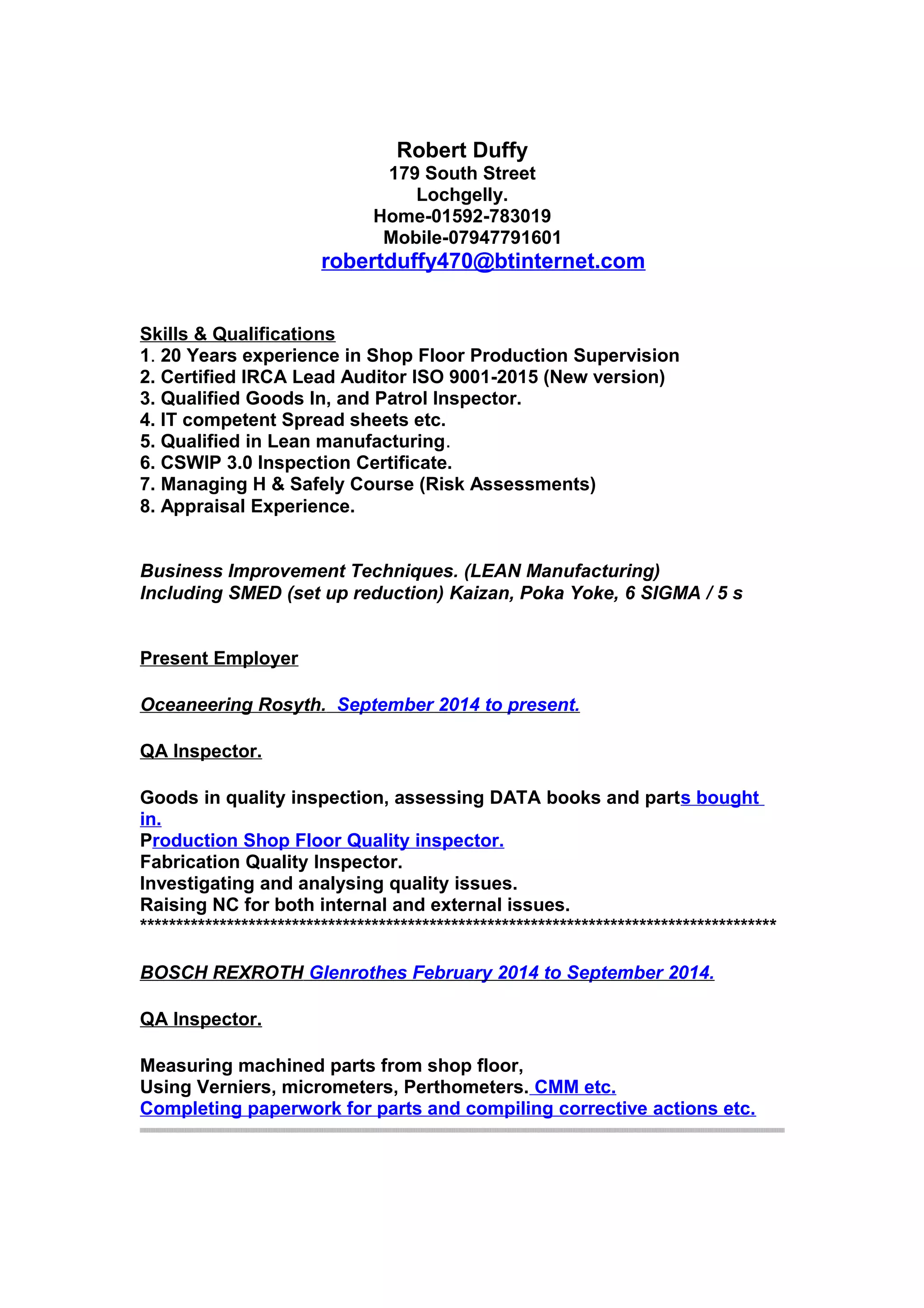

Robert Duffy has over 20 years of experience in shop floor production supervision. He currently works as a QA Inspector for Oceaneering Rosyth where he performs goods in quality inspection, production shop floor quality inspection, and fabrication quality inspection. Prior to his current role, he worked as a QA Inspector for BOSCH REXROTH Glenrothes where he measured machined parts and completed paperwork for parts and corrective actions. He has extensive experience supervising production operations and teams of up to 30 operators at Fife Fabrications from 1990 to 2013.