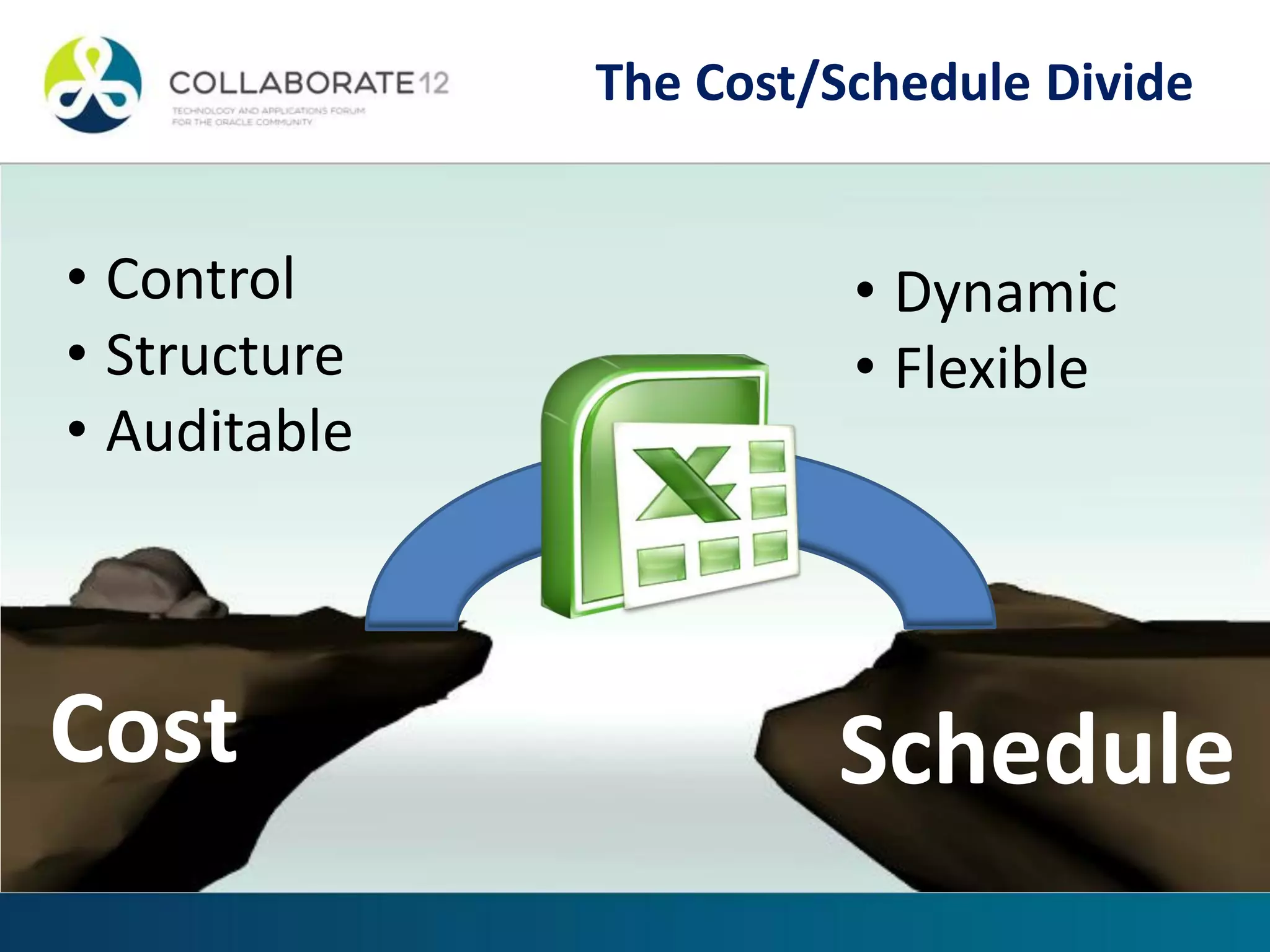

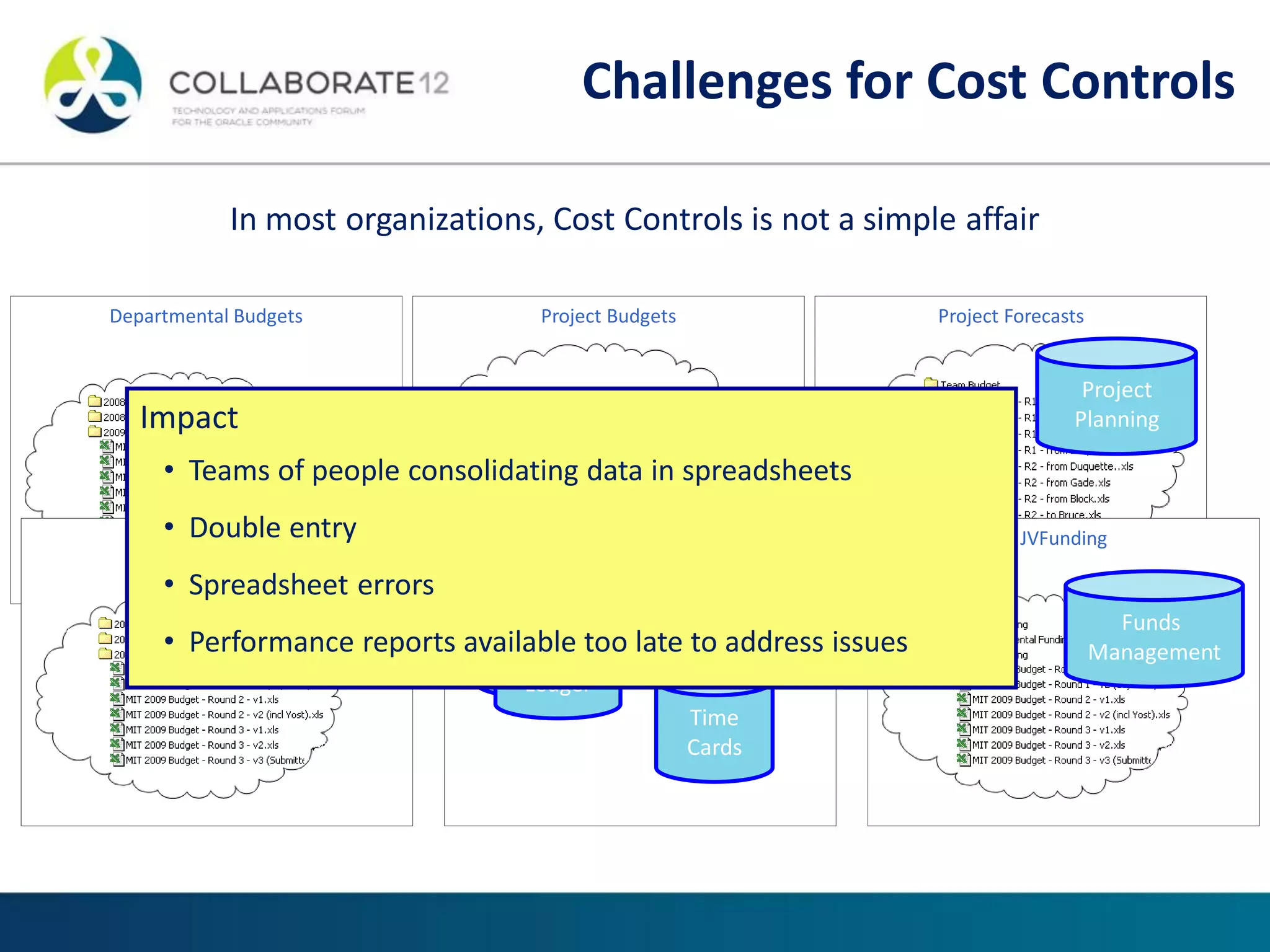

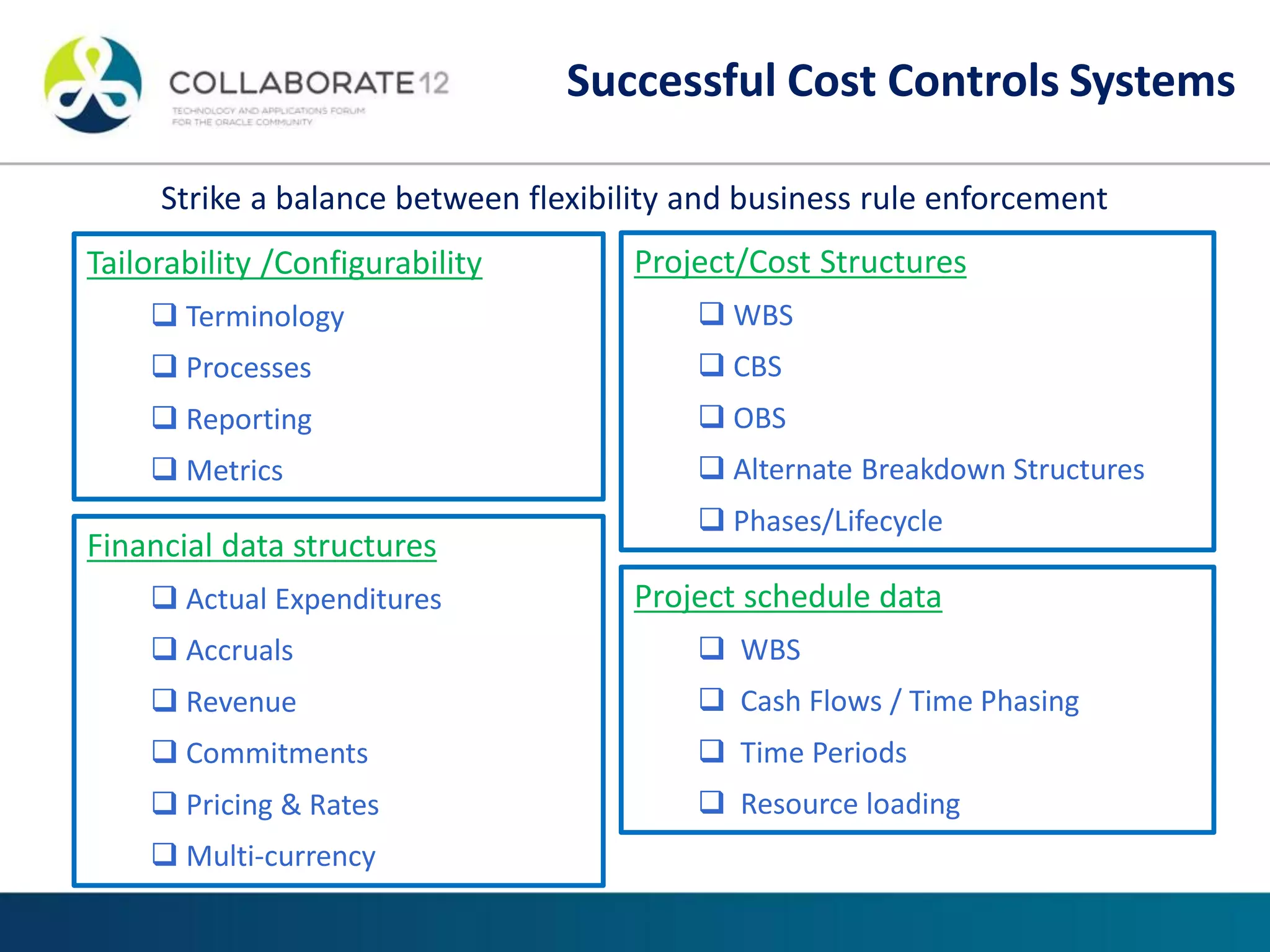

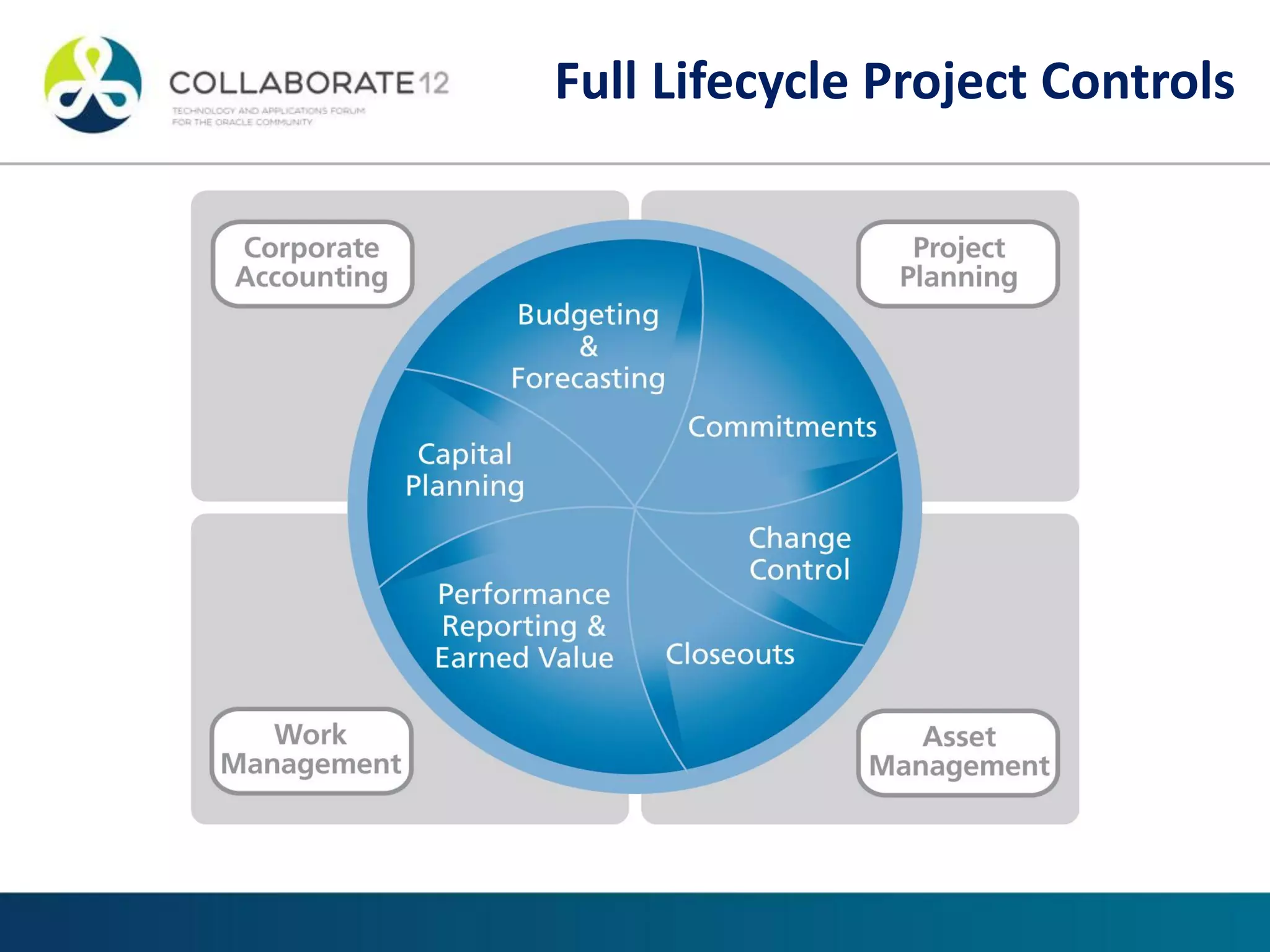

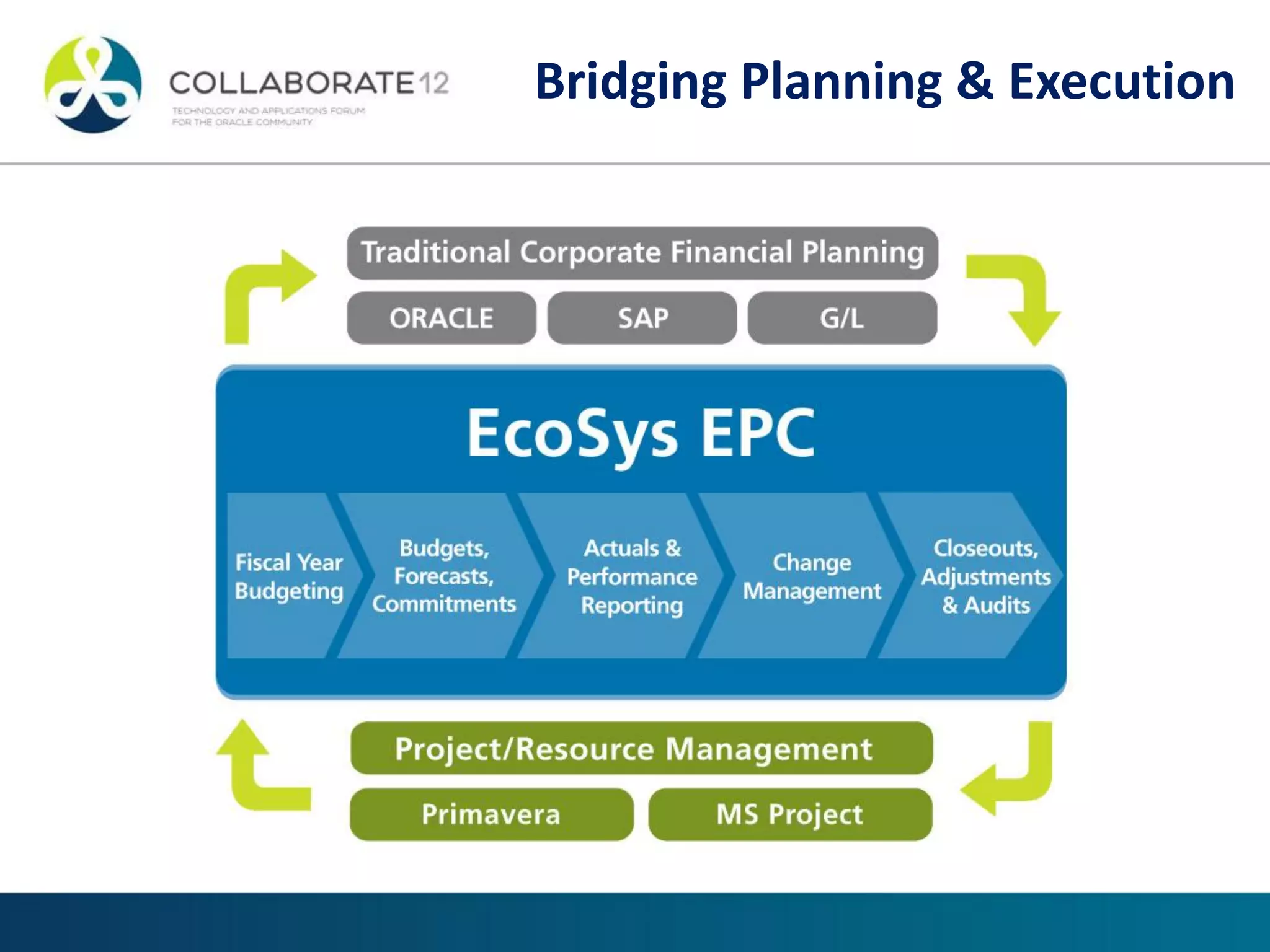

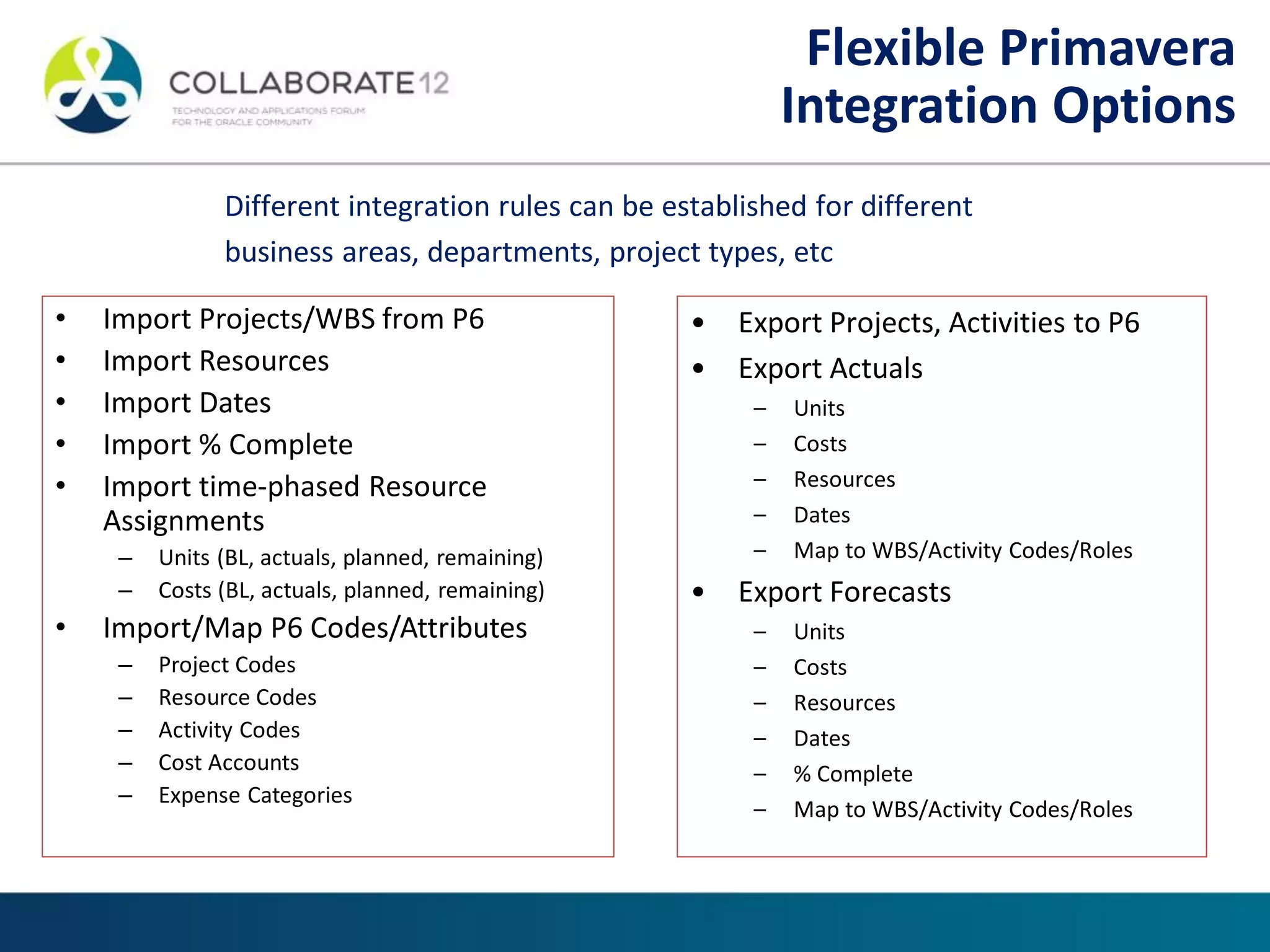

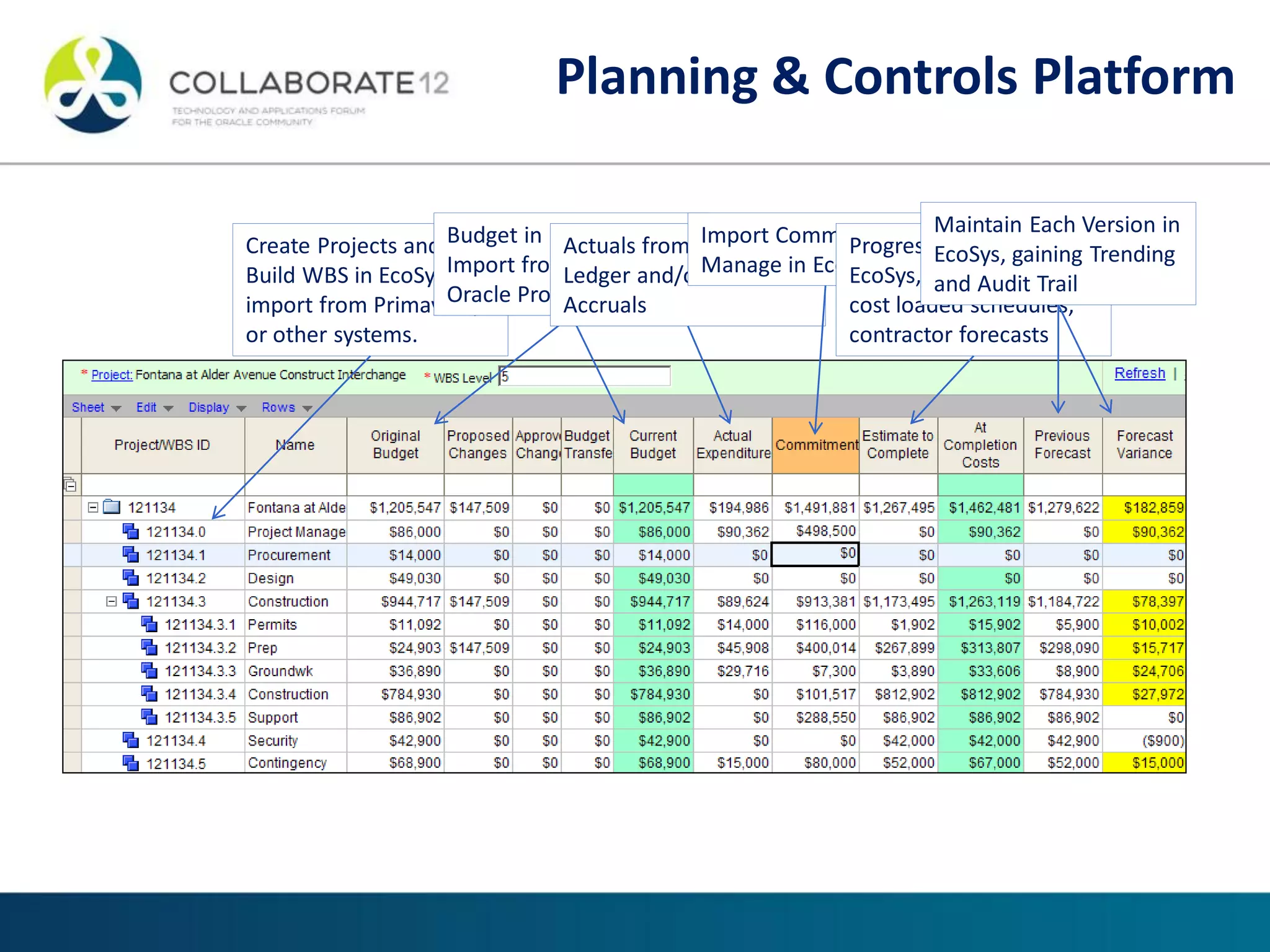

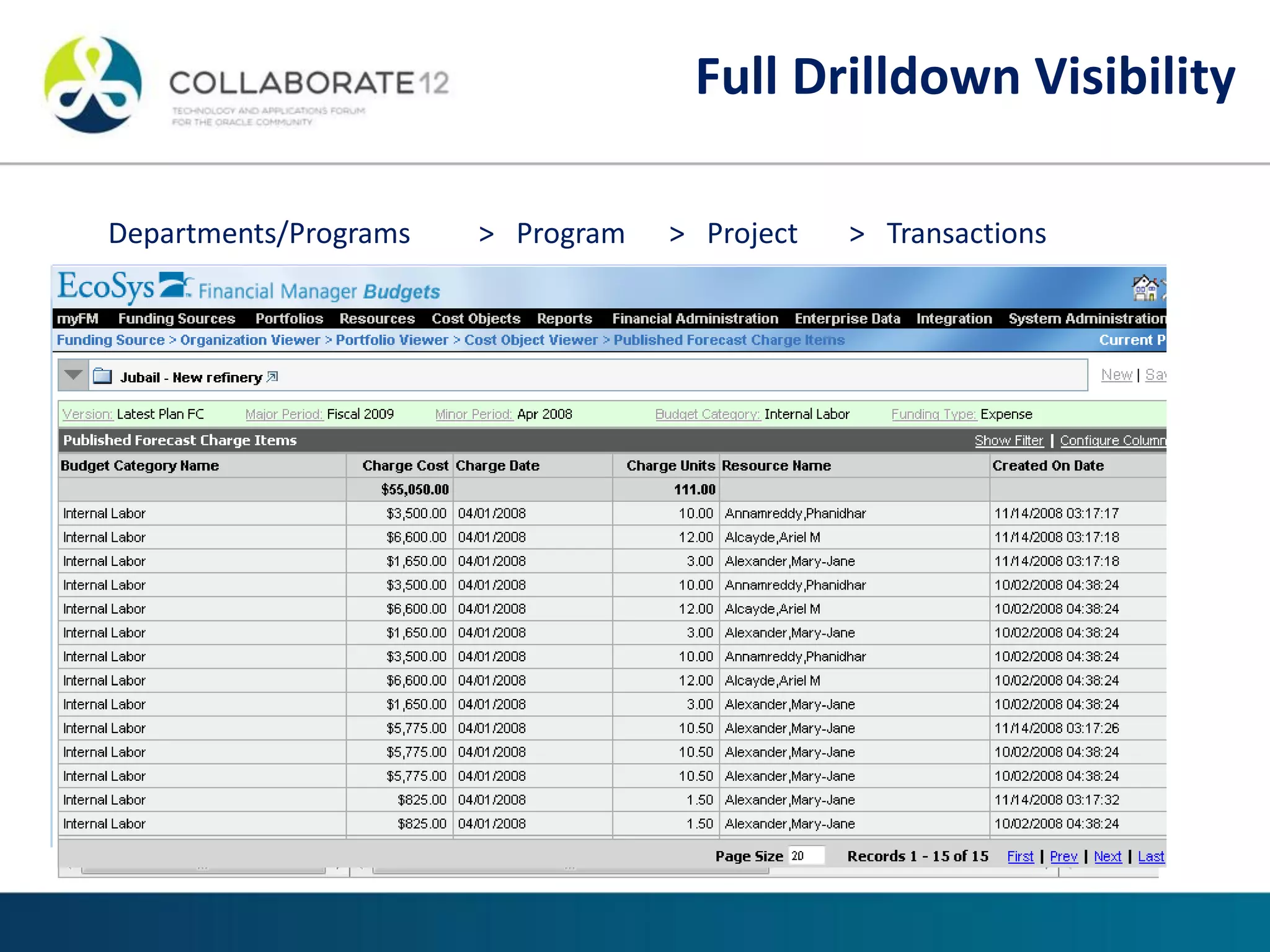

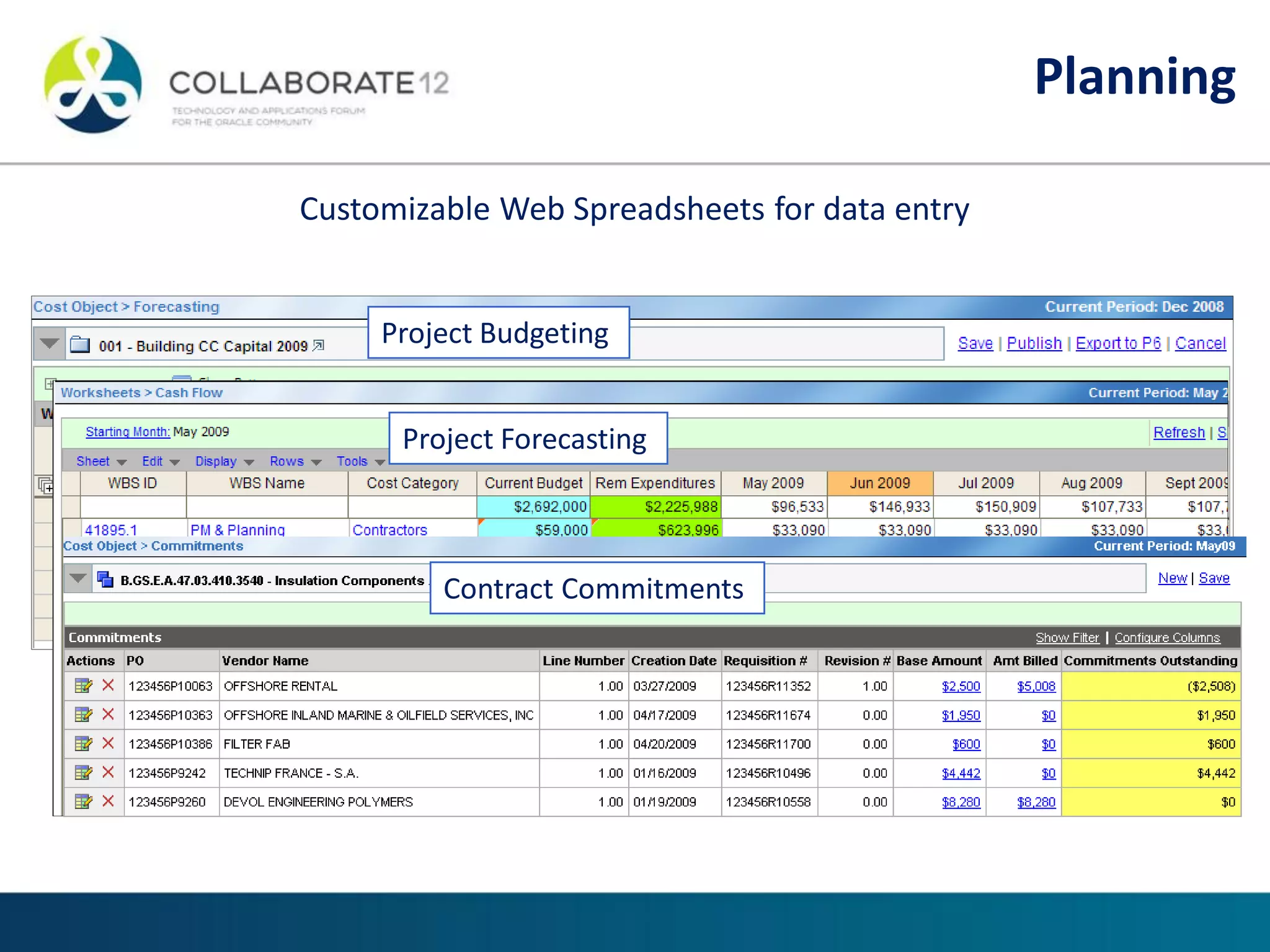

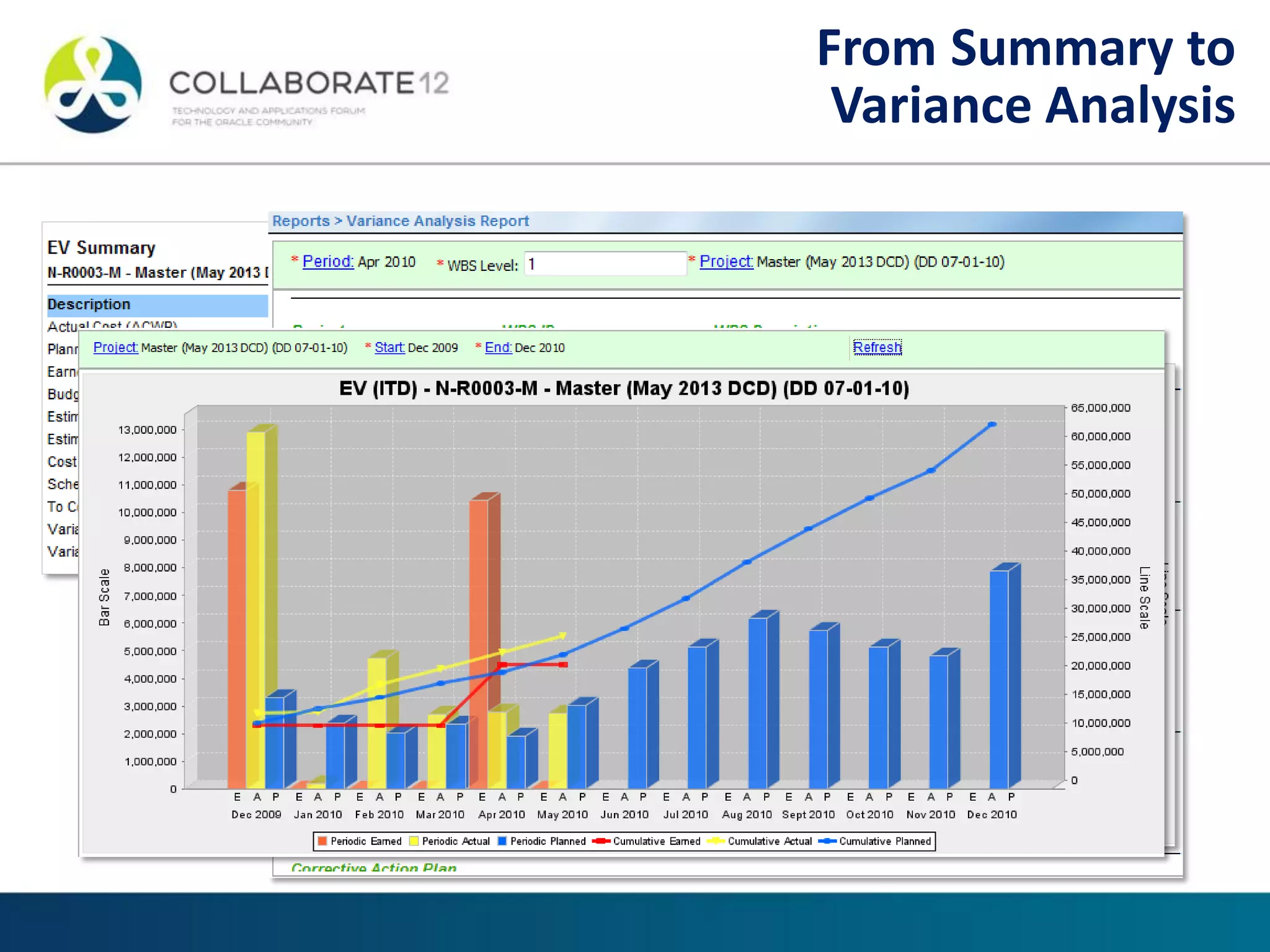

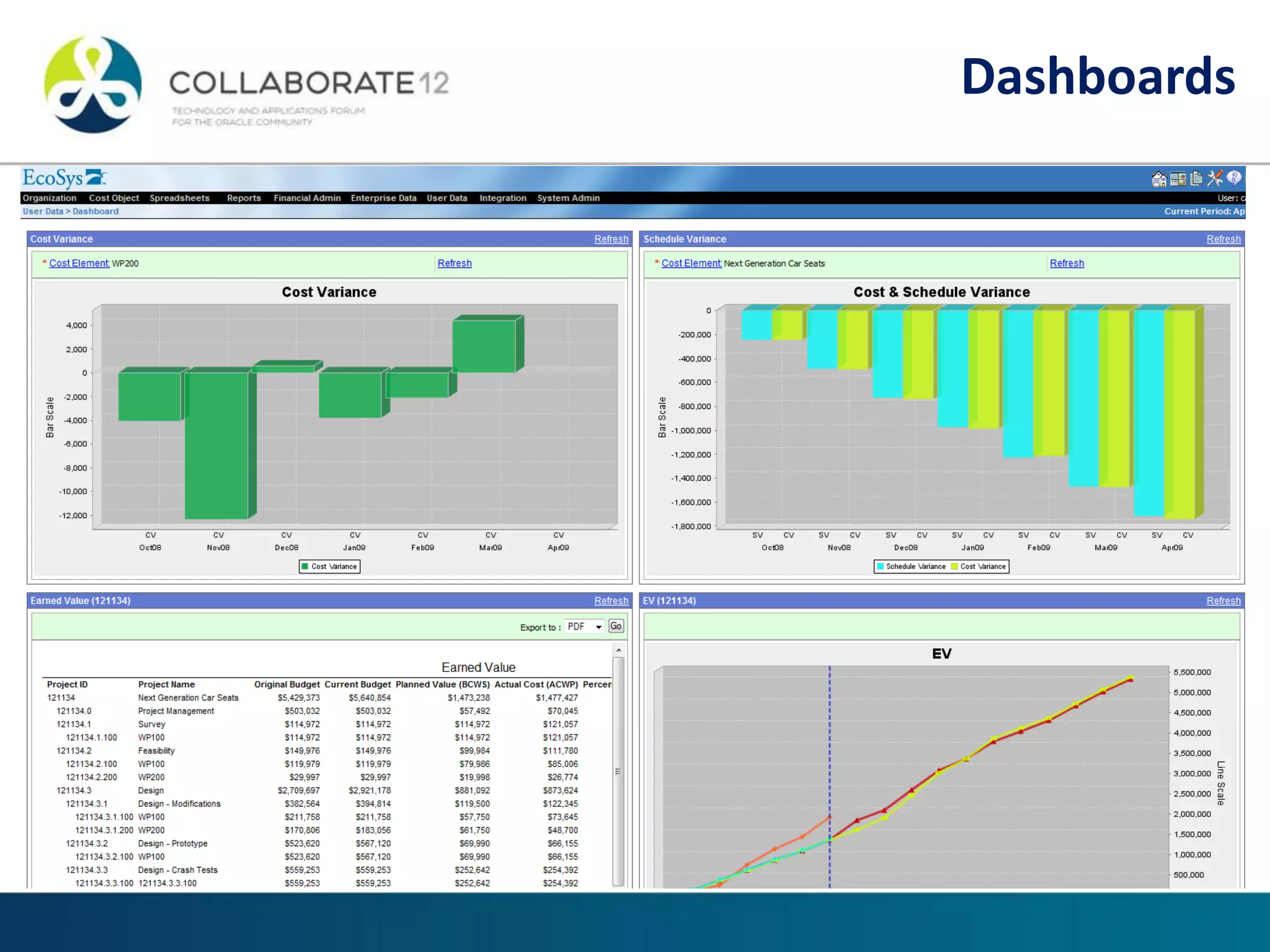

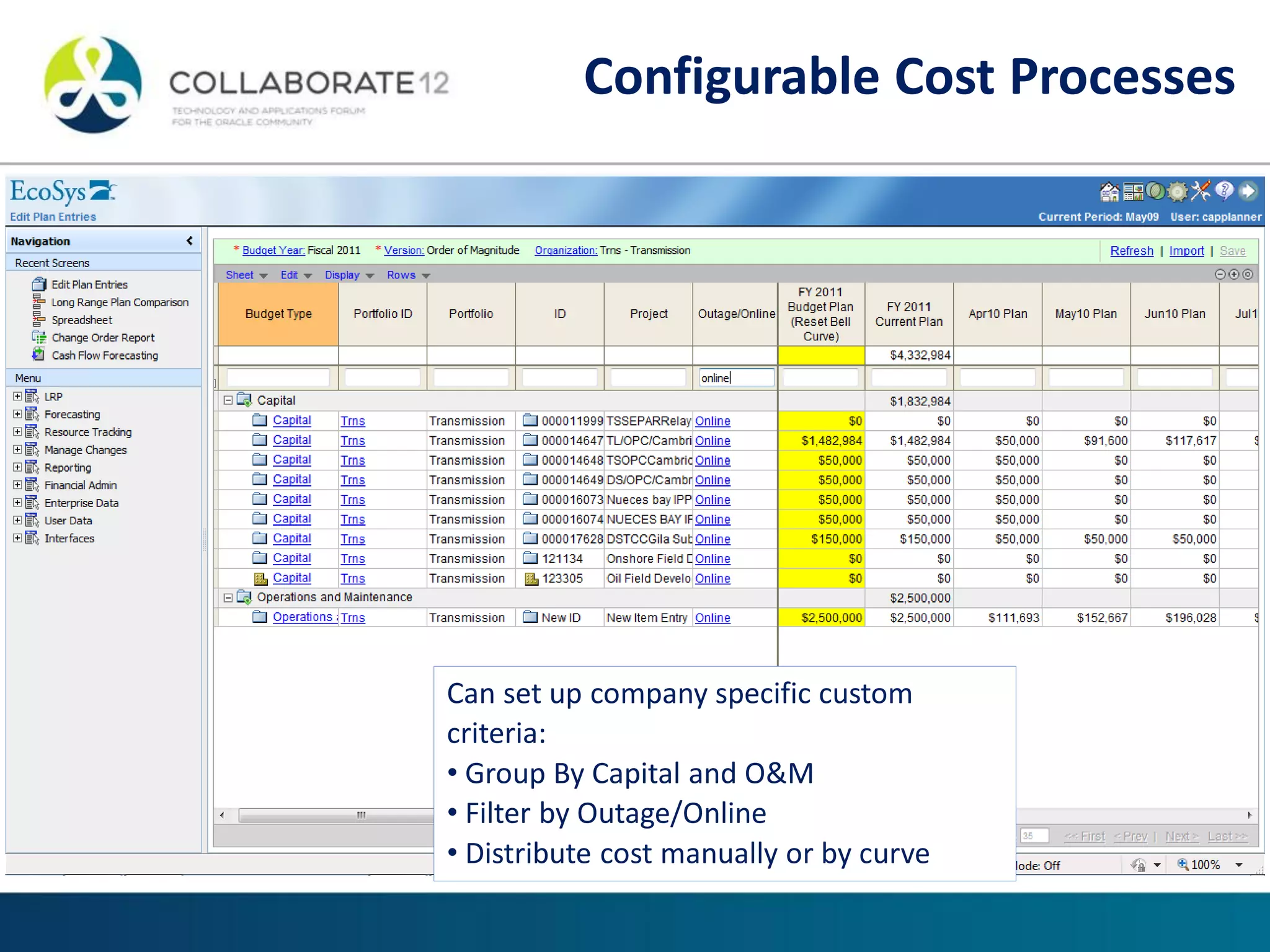

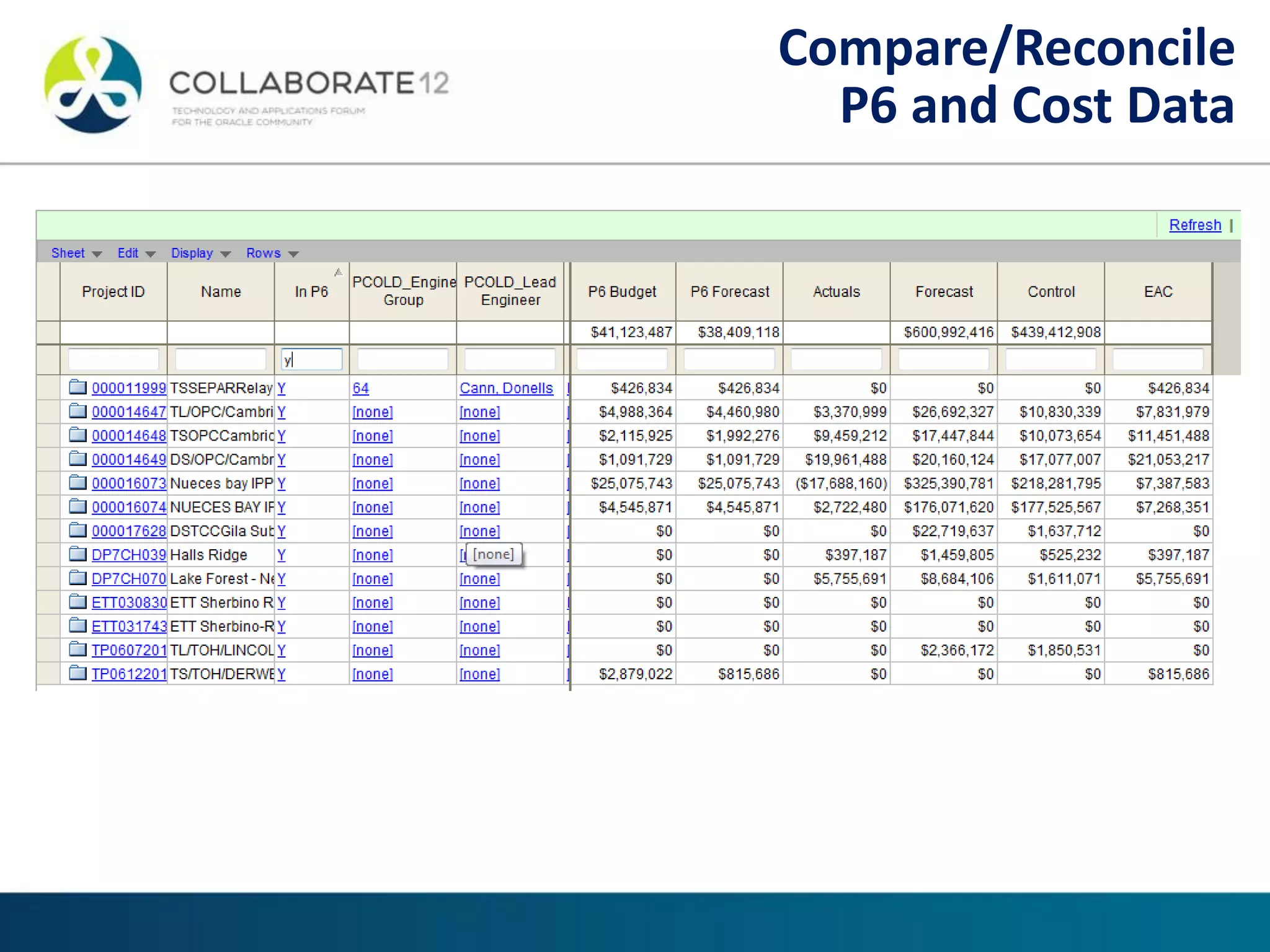

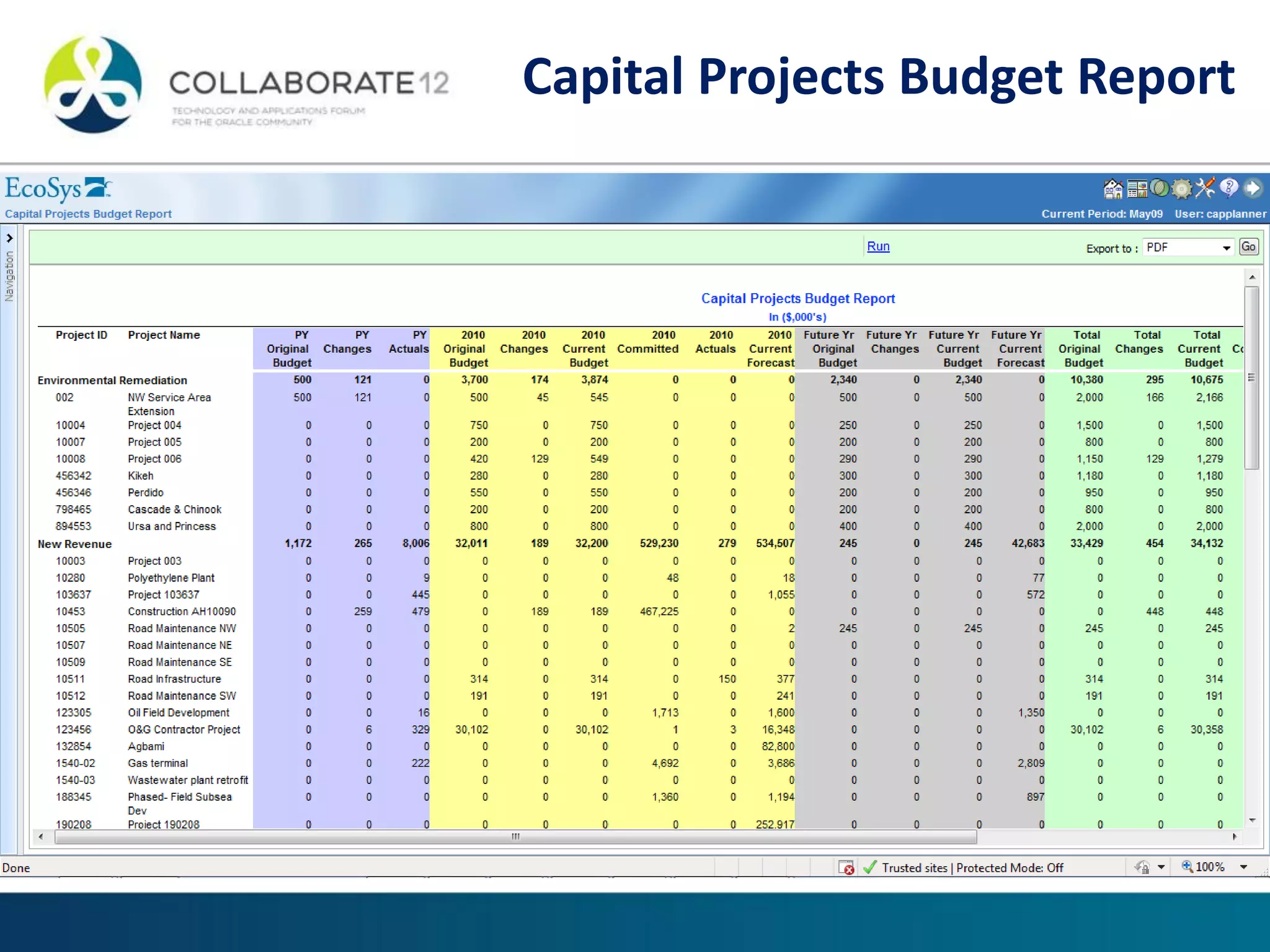

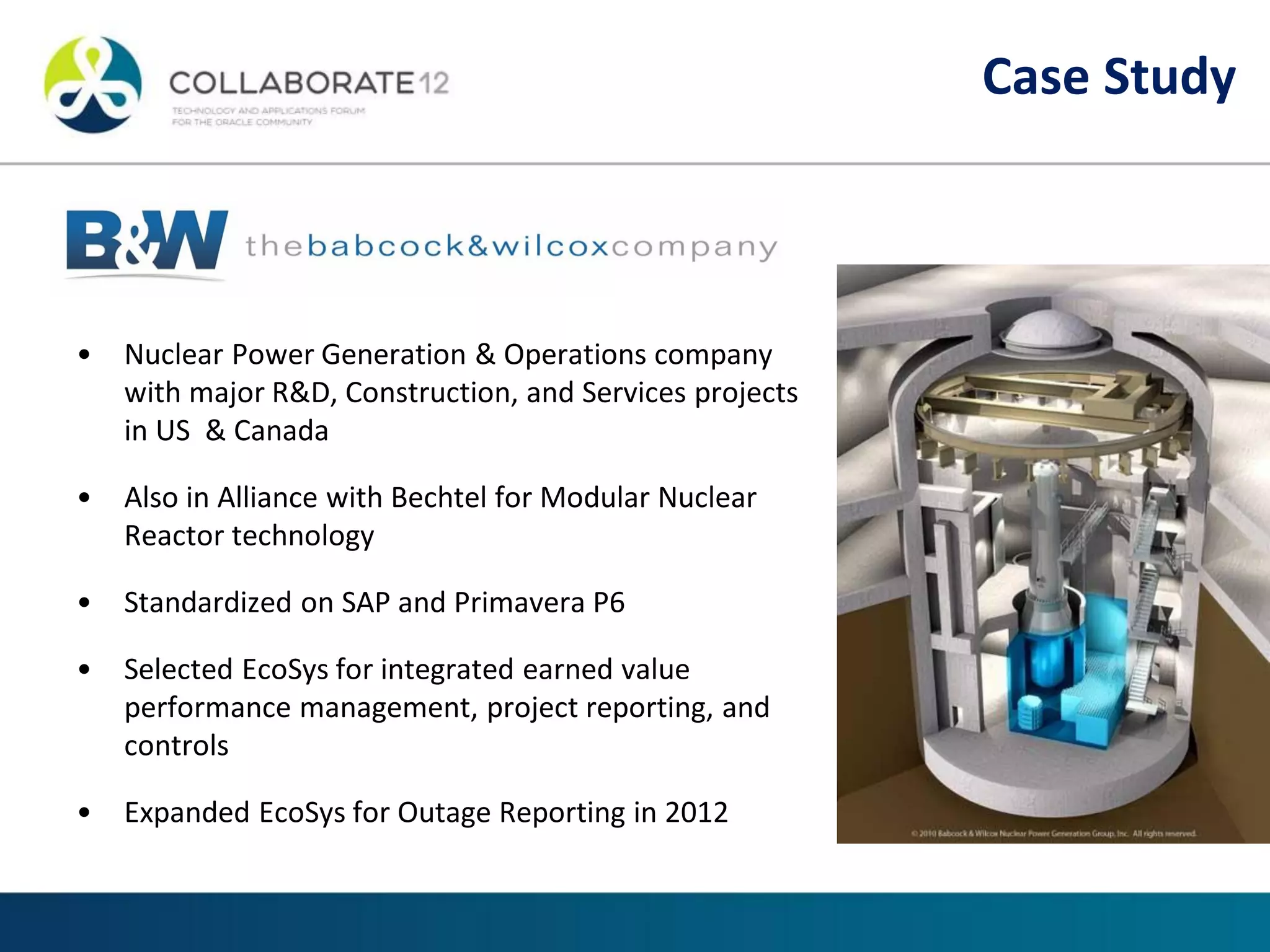

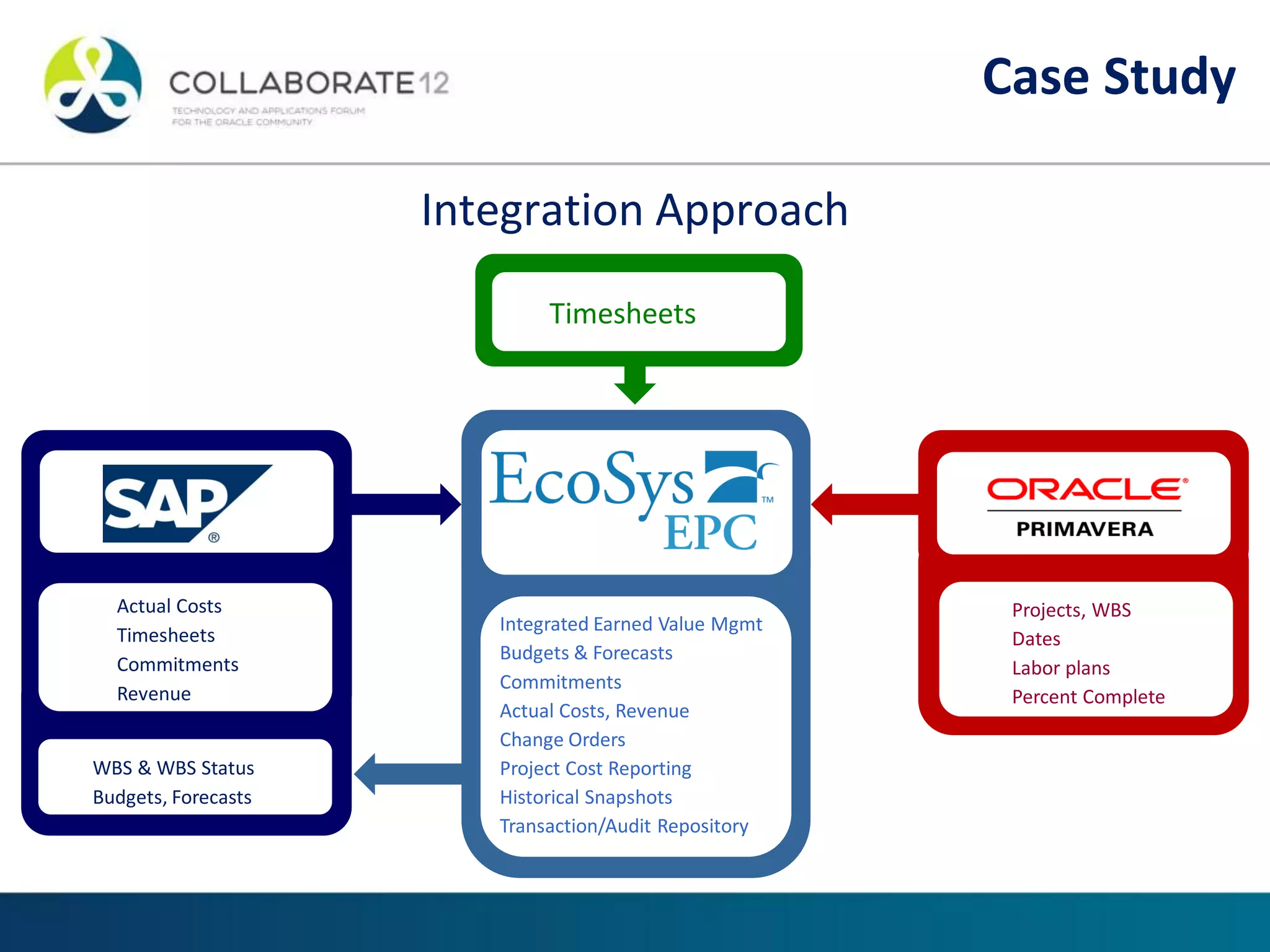

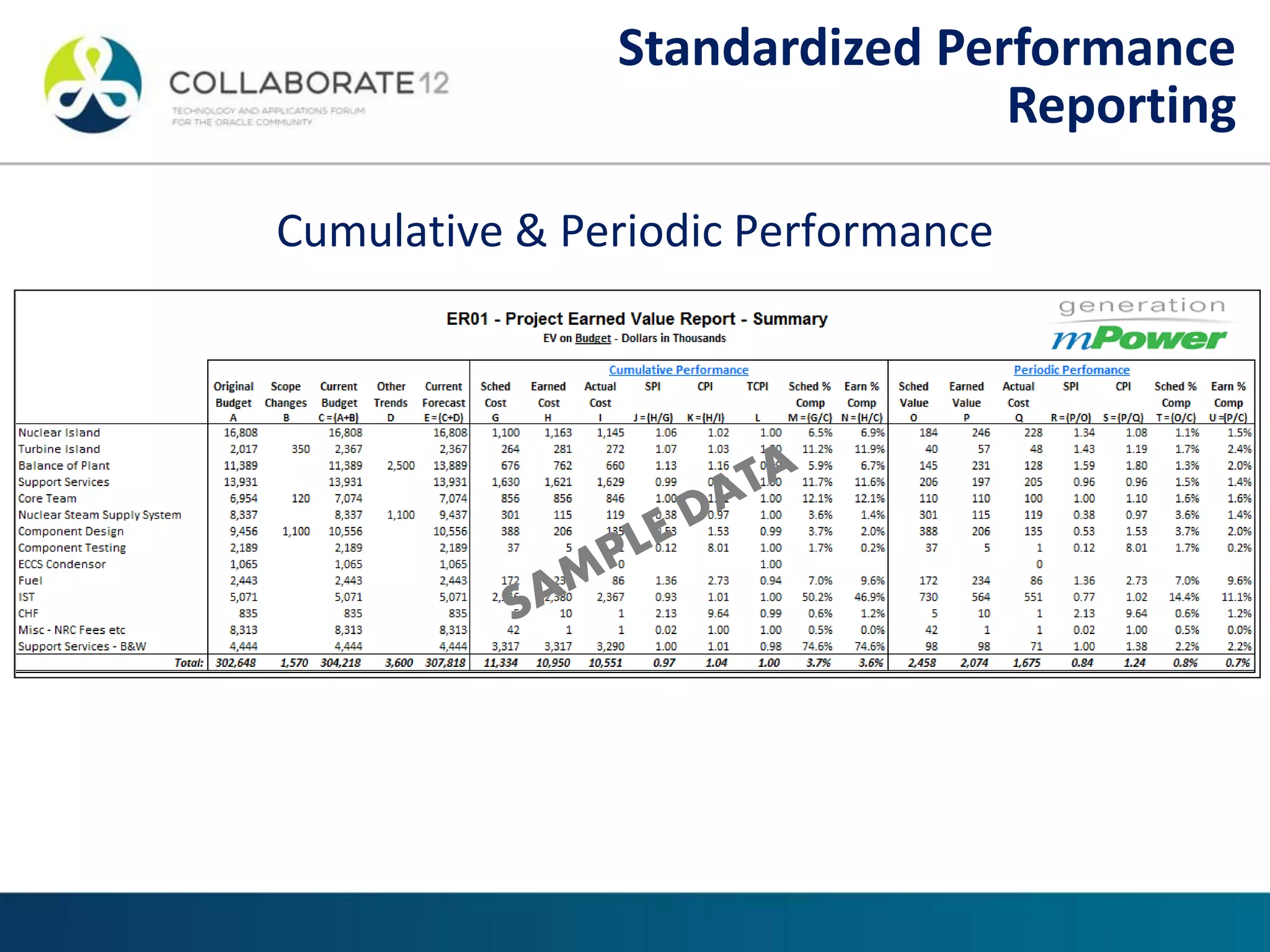

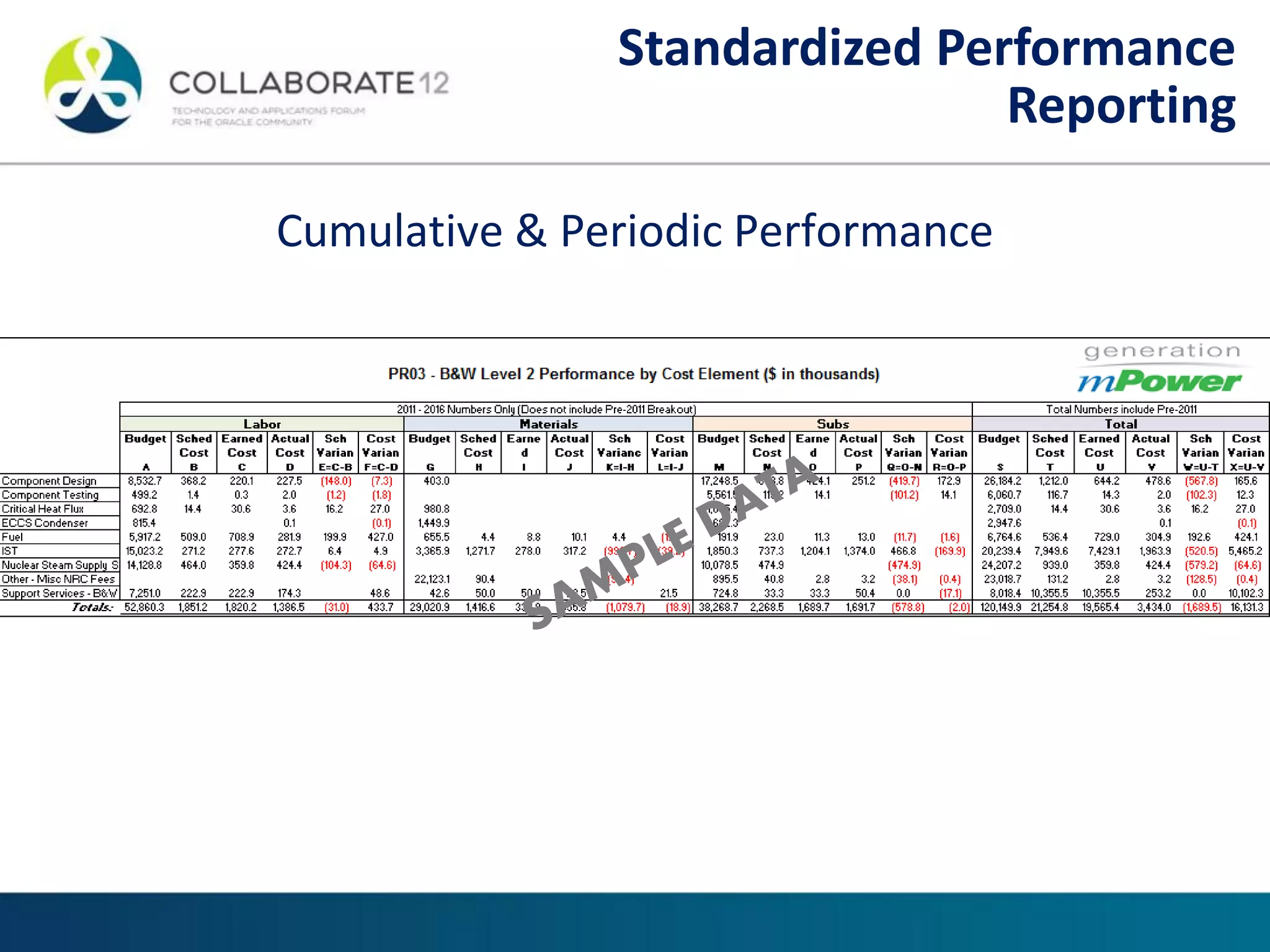

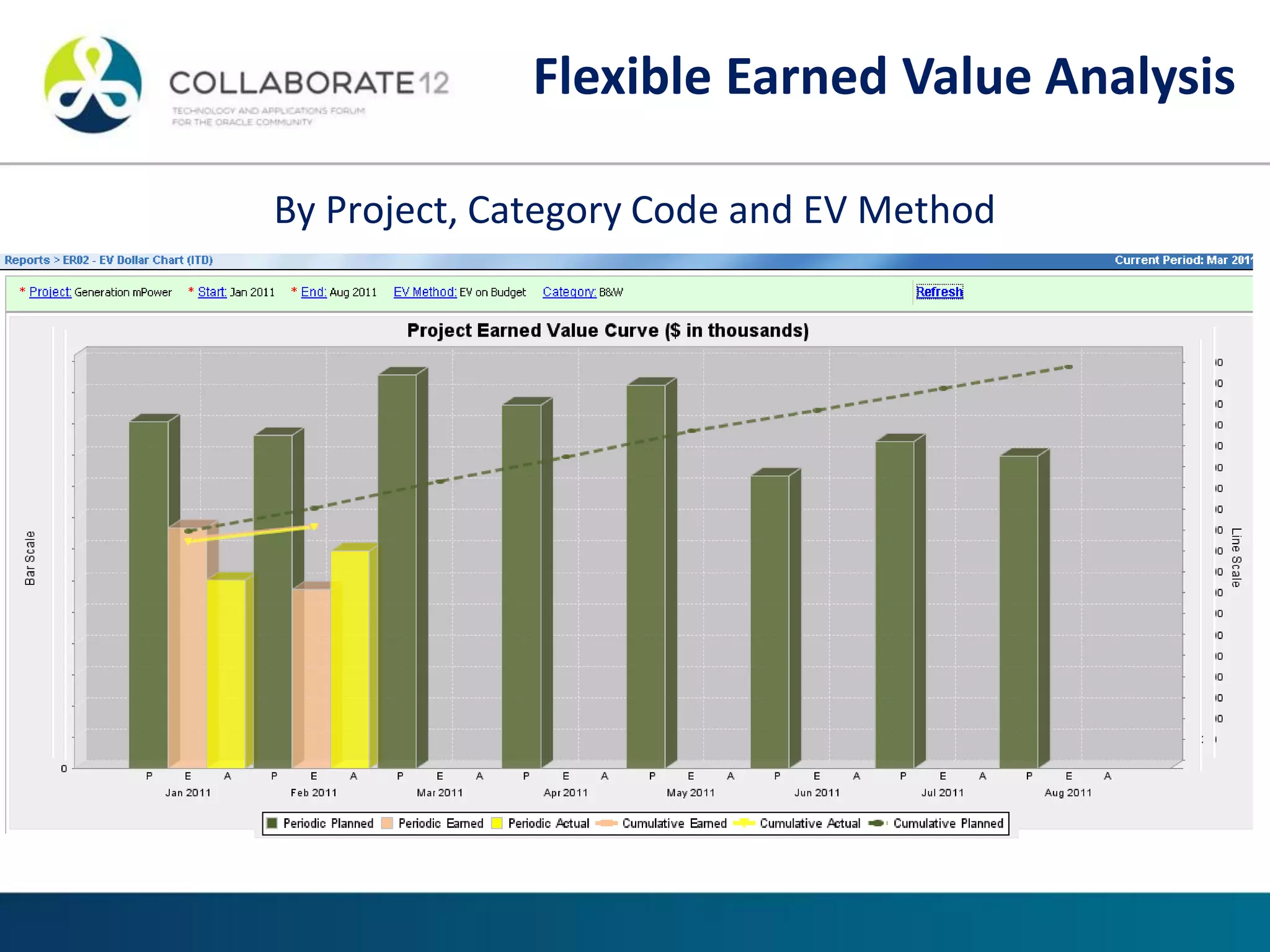

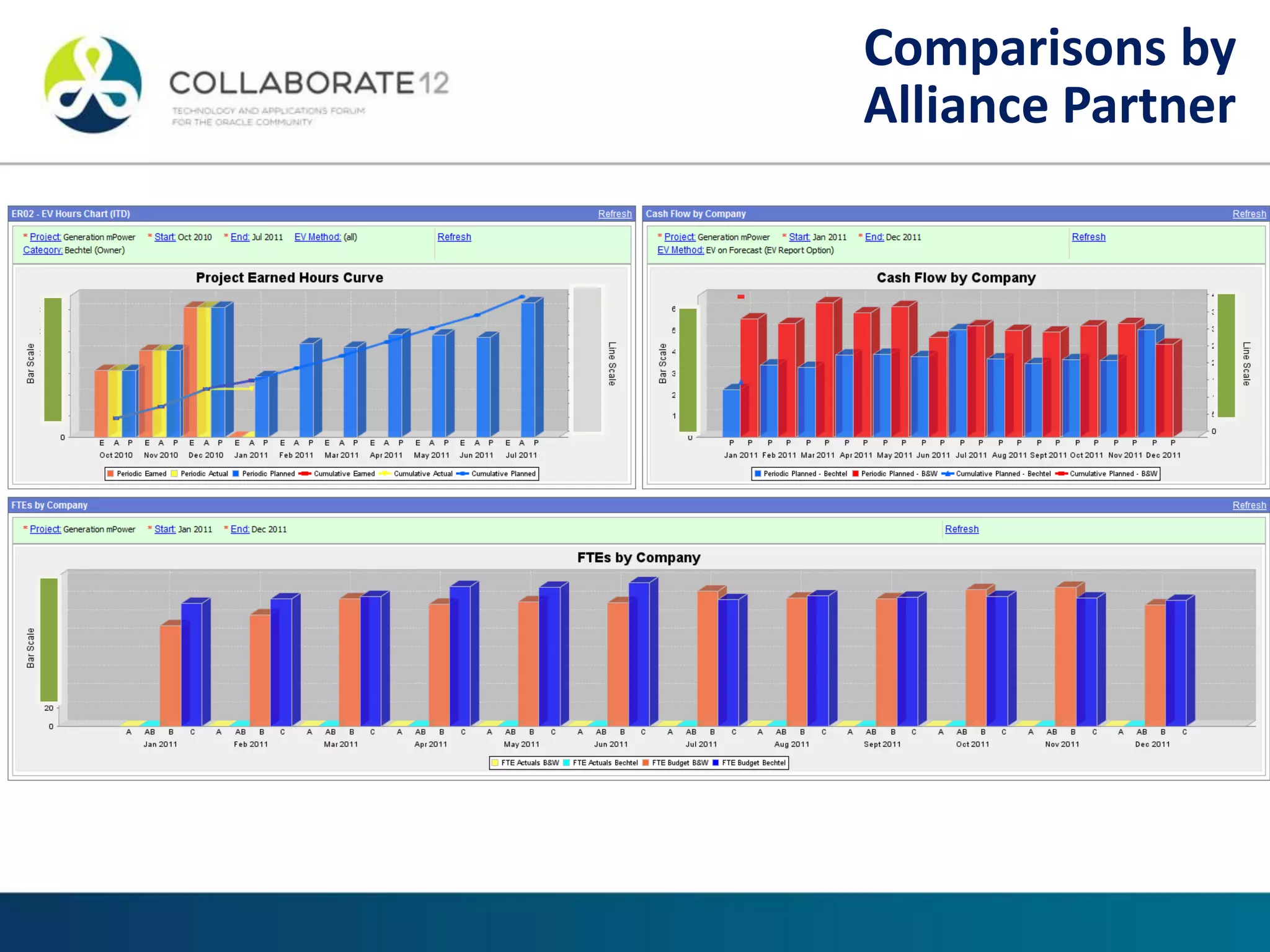

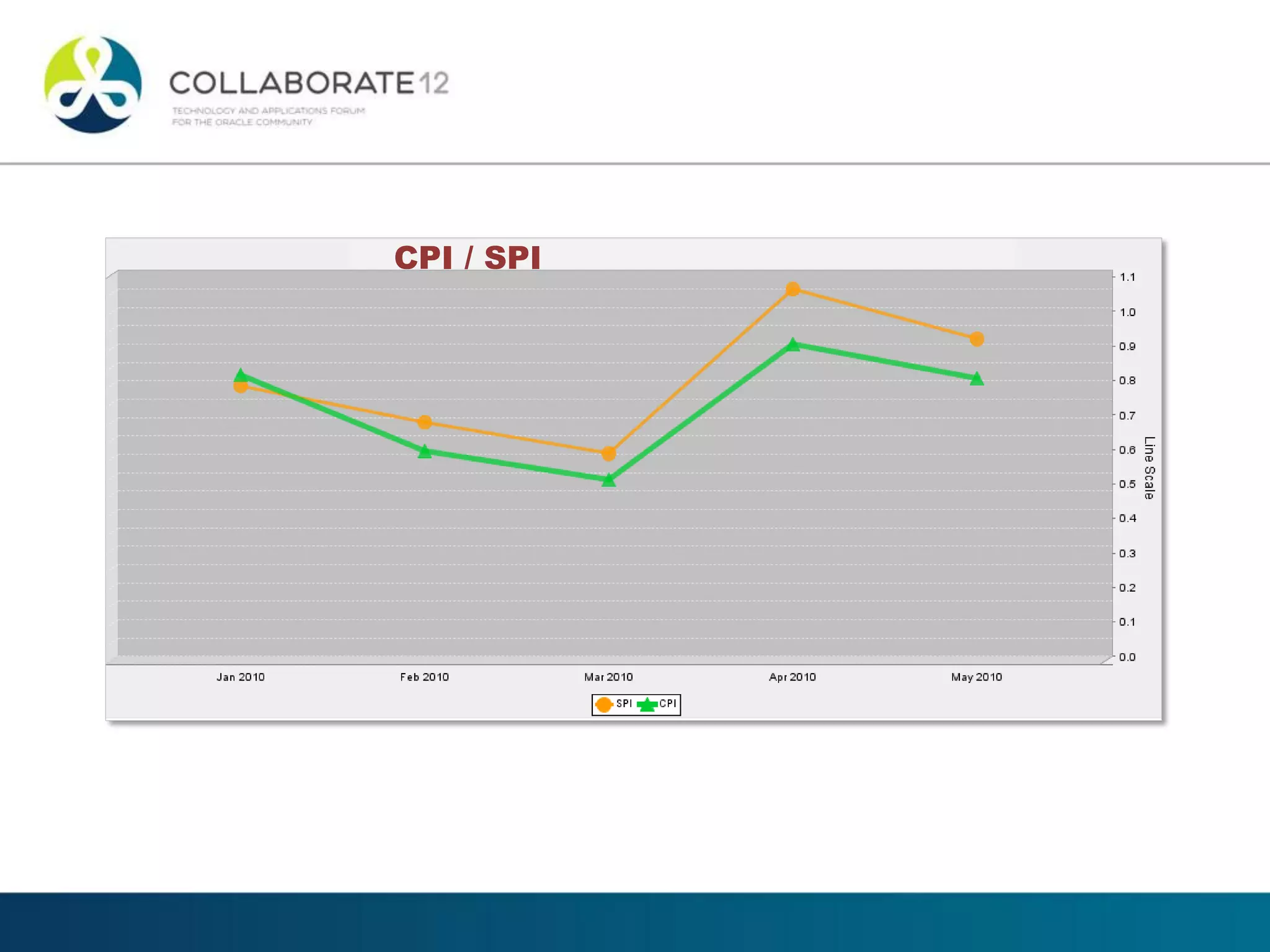

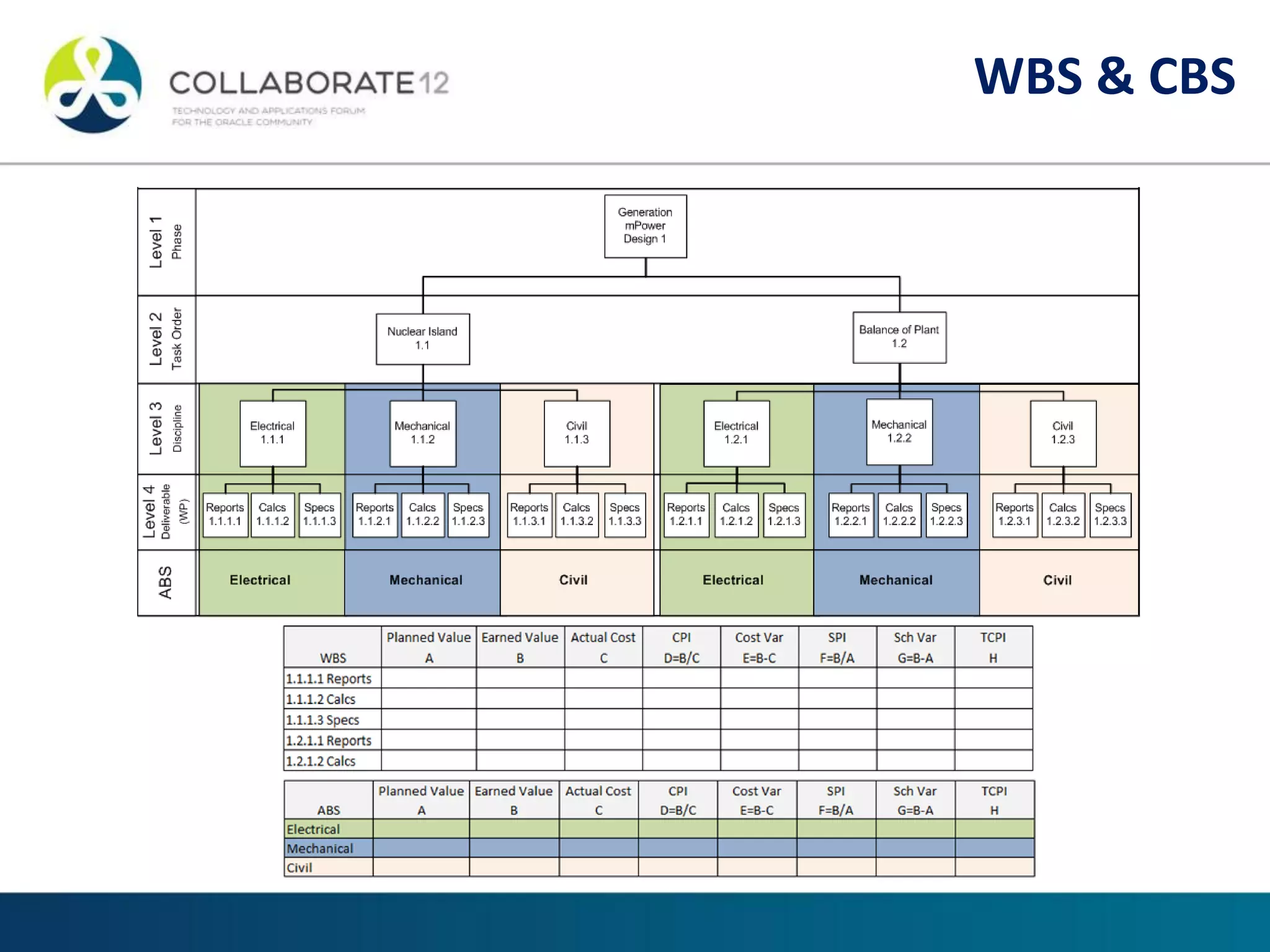

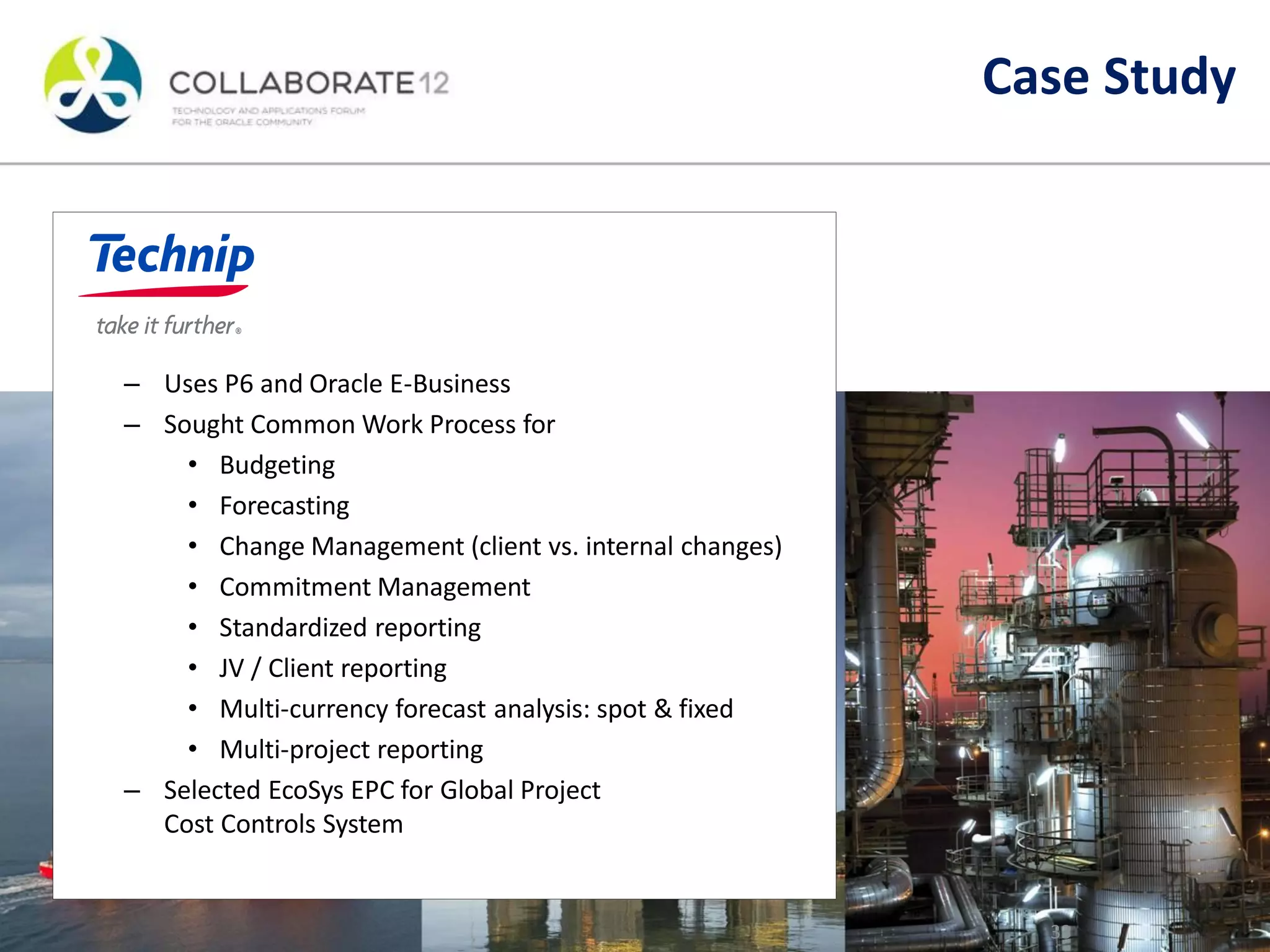

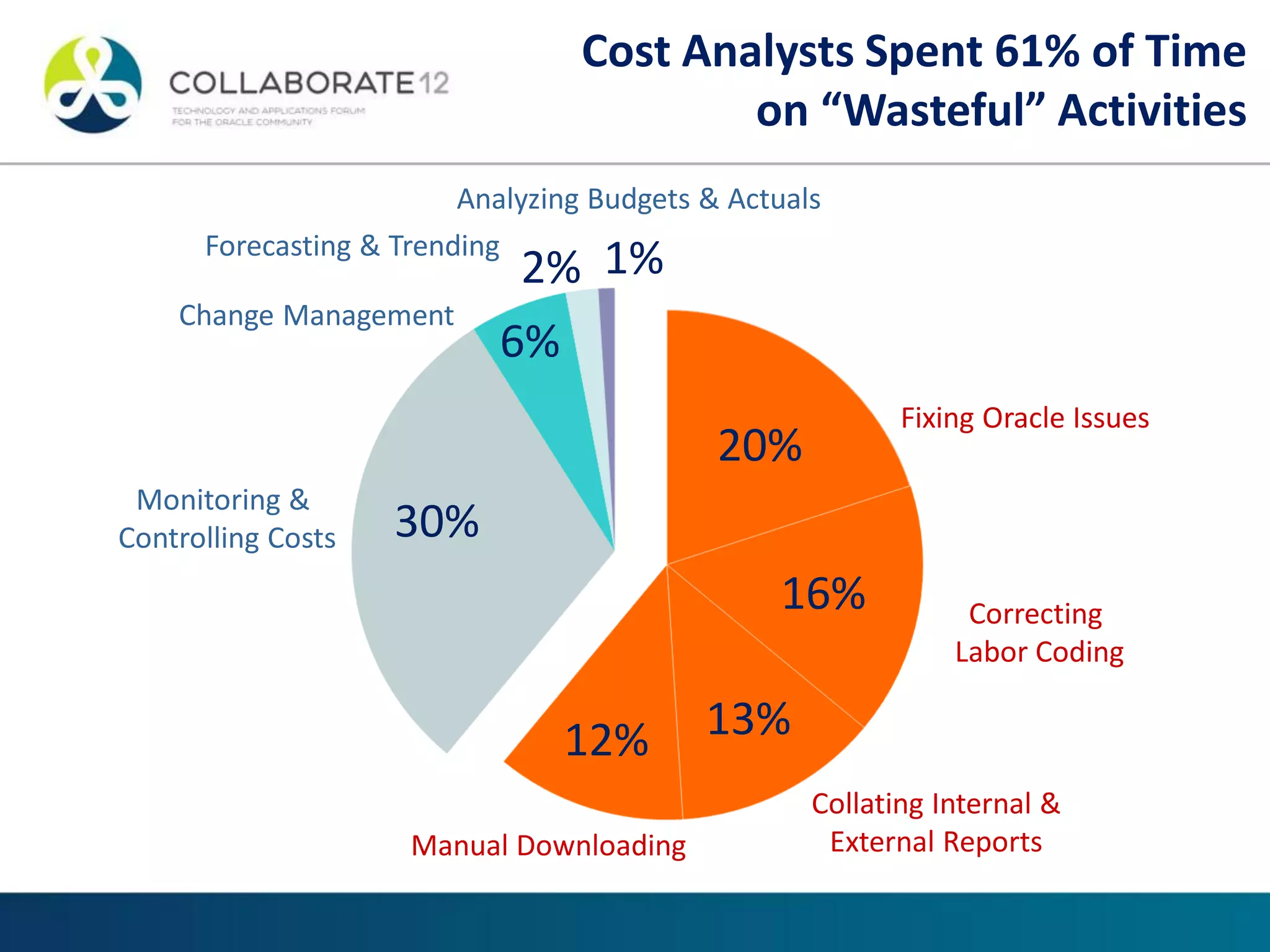

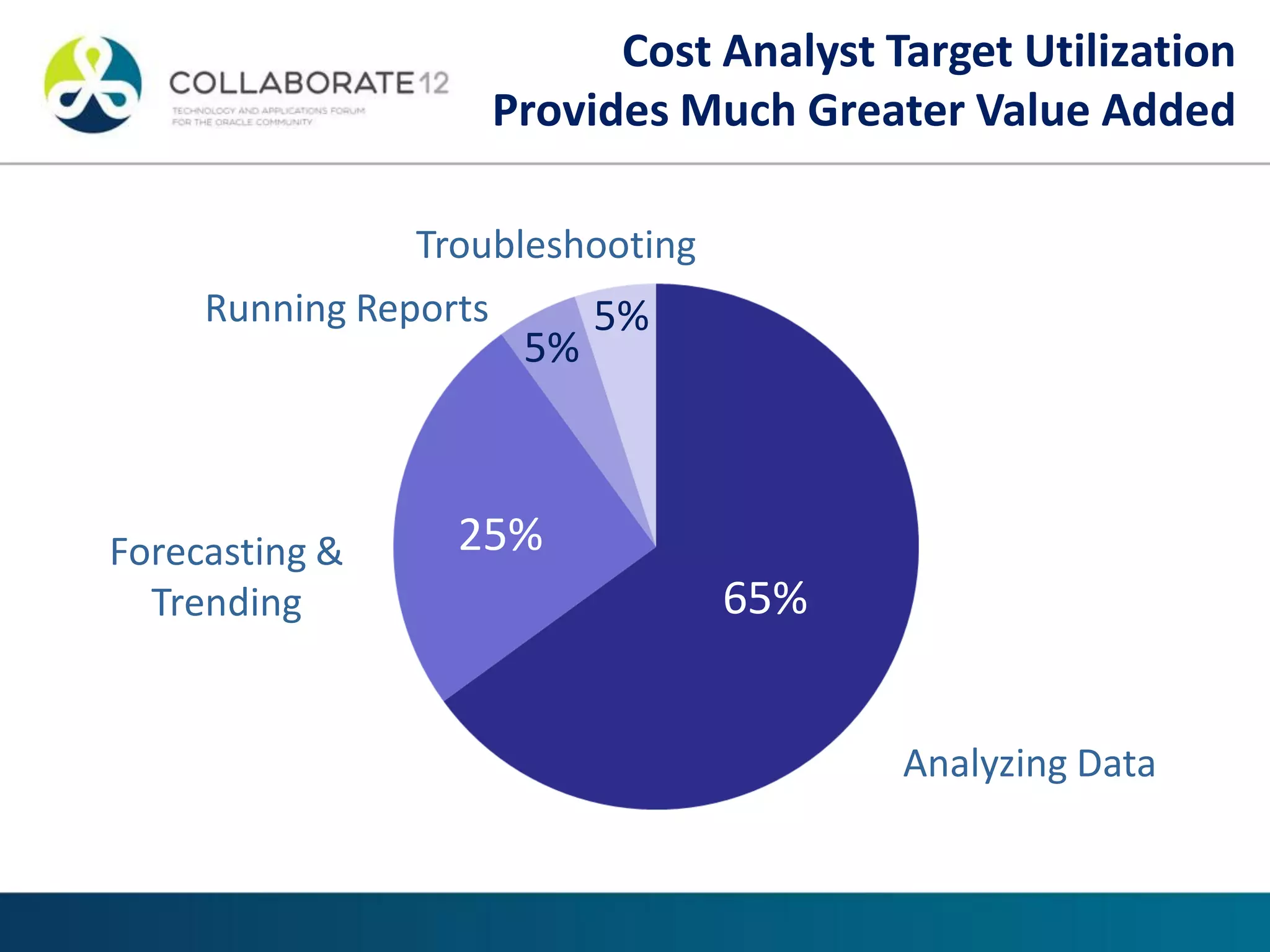

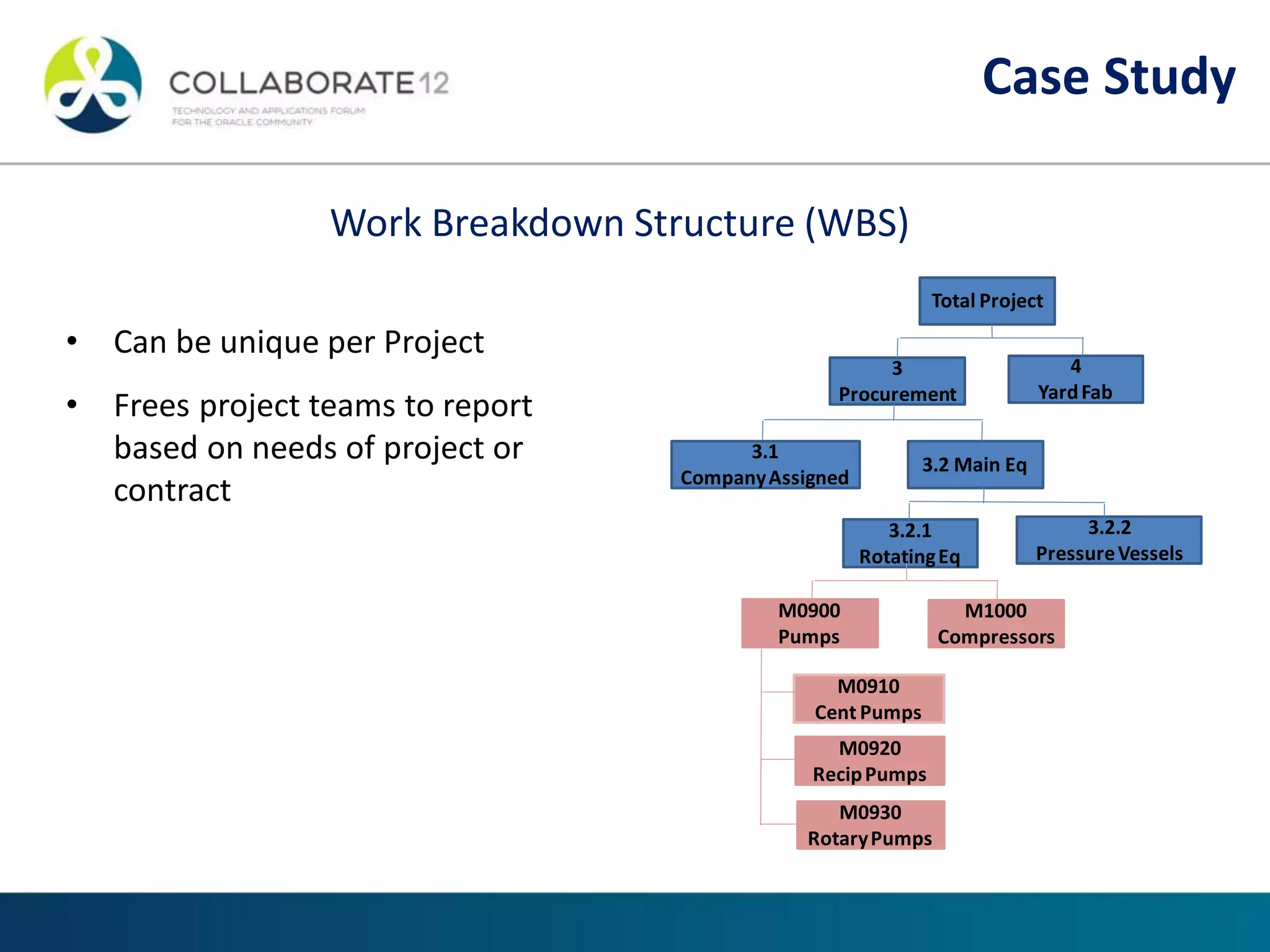

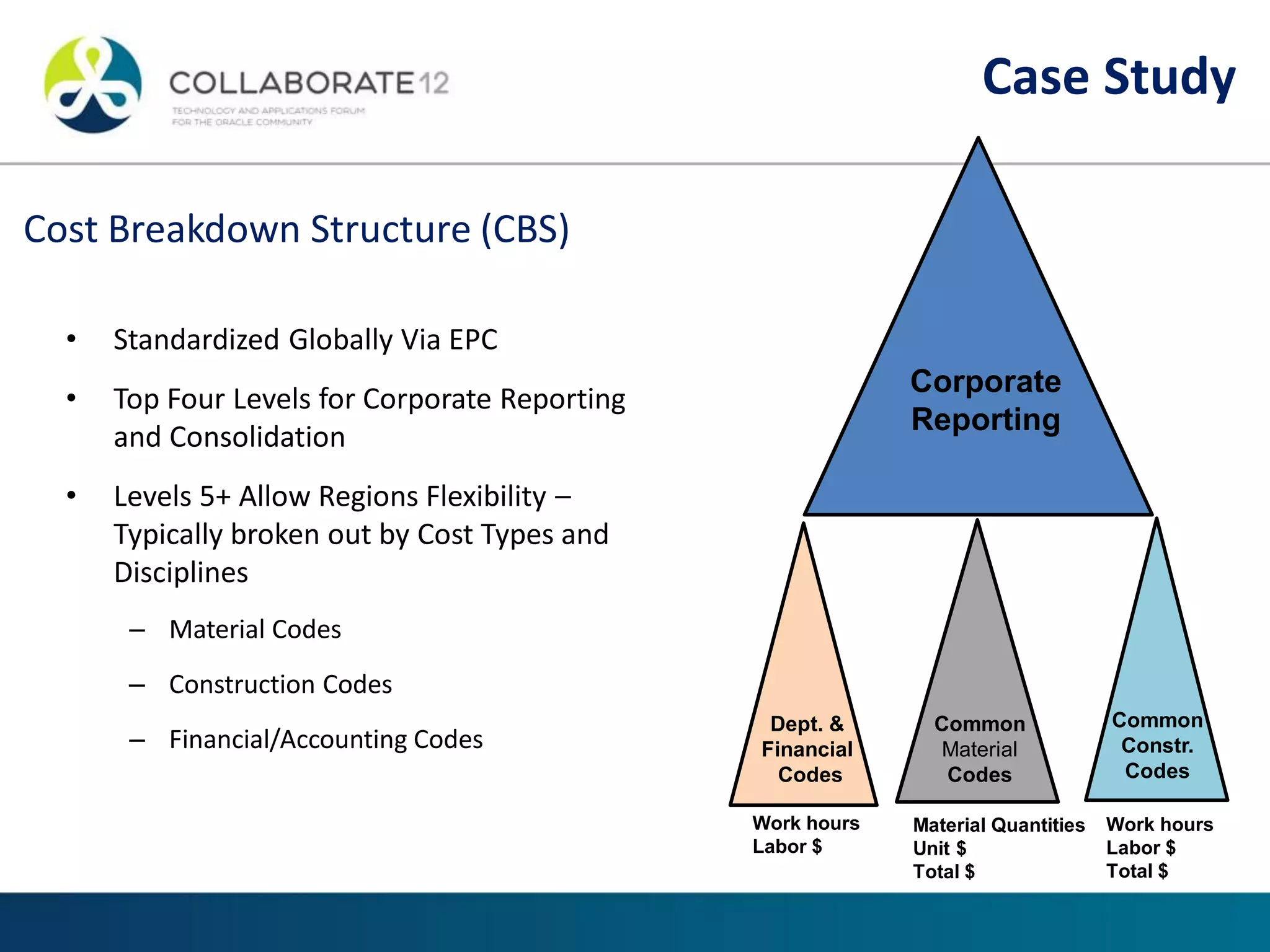

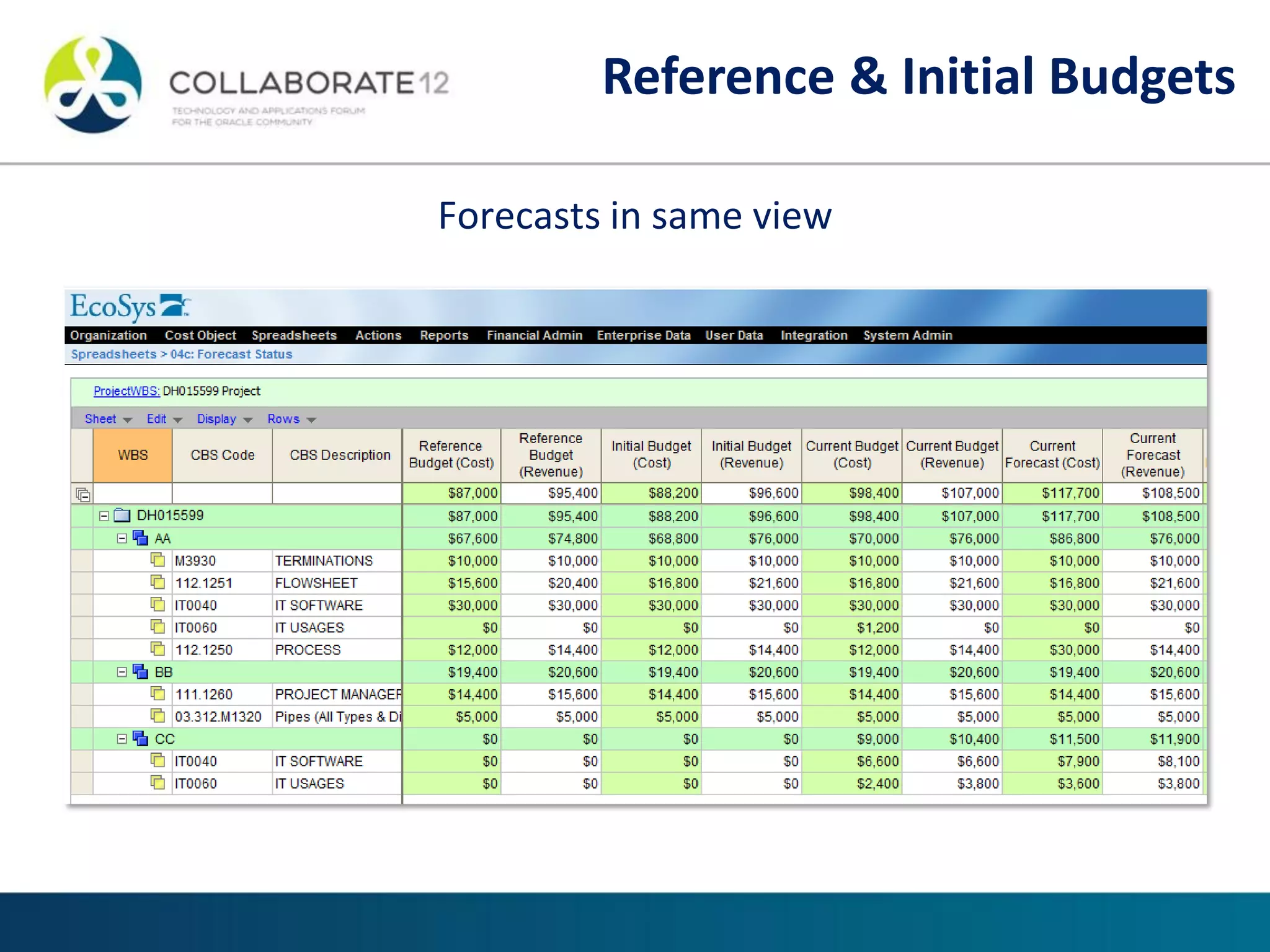

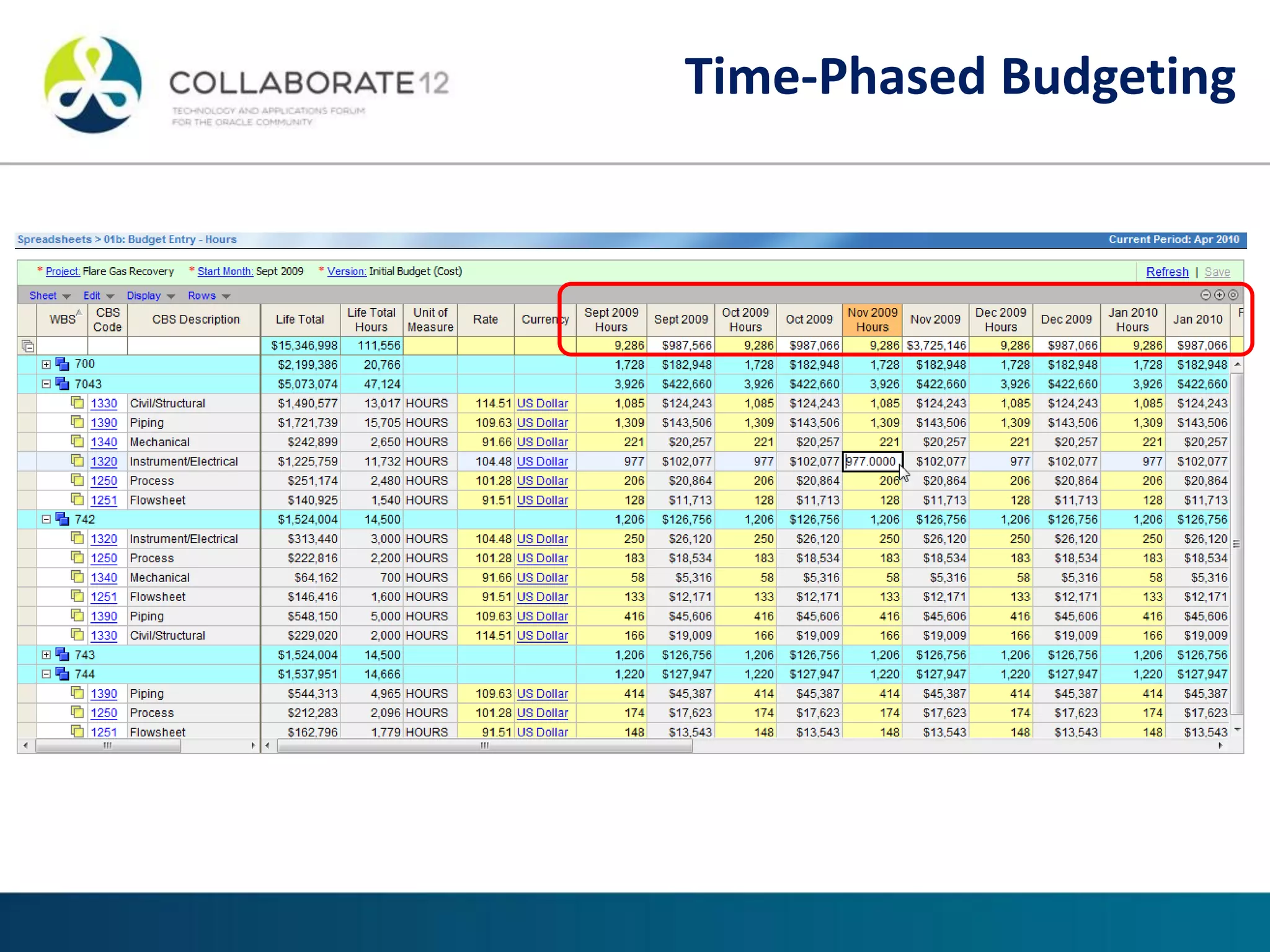

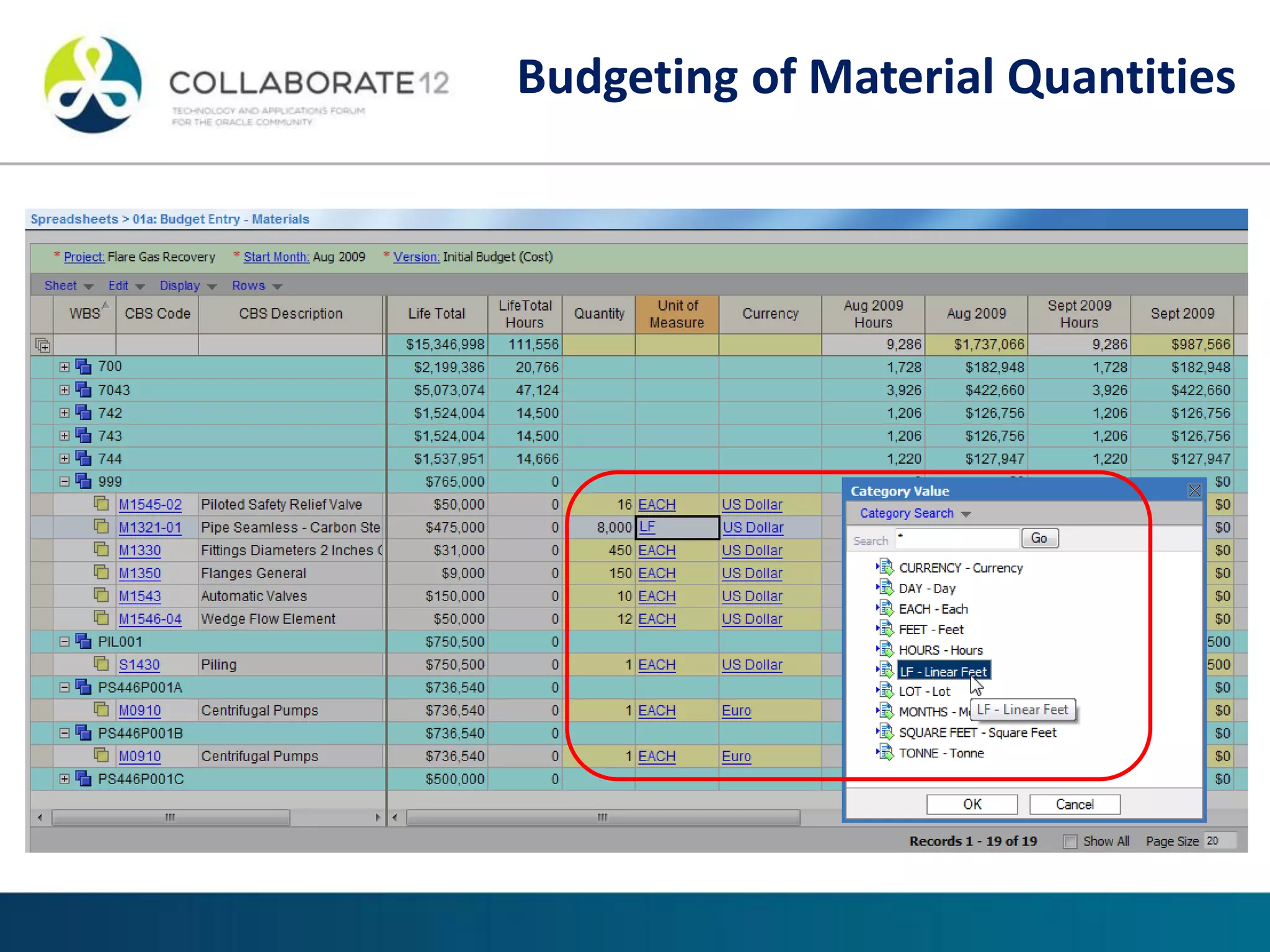

This document discusses integrating project cost systems with scheduling systems like Oracle Primavera. It outlines challenges with the traditional divide between cost and schedule data. It presents case studies of companies that implemented EcoSys software to bridge this gap. Benefits included increased visibility, efficiency, accuracy, and standardized processes to improve financial performance and resource optimization.