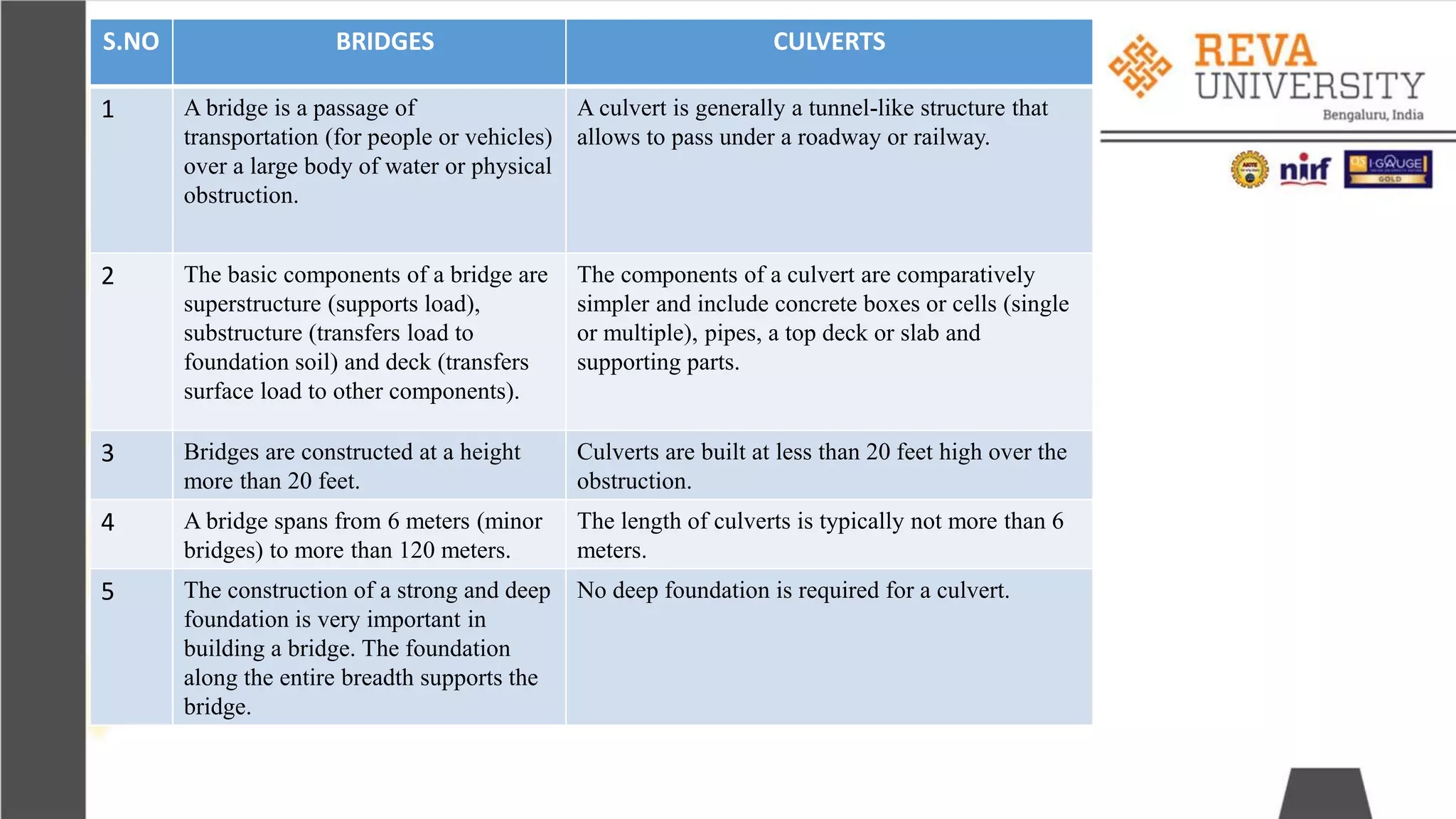

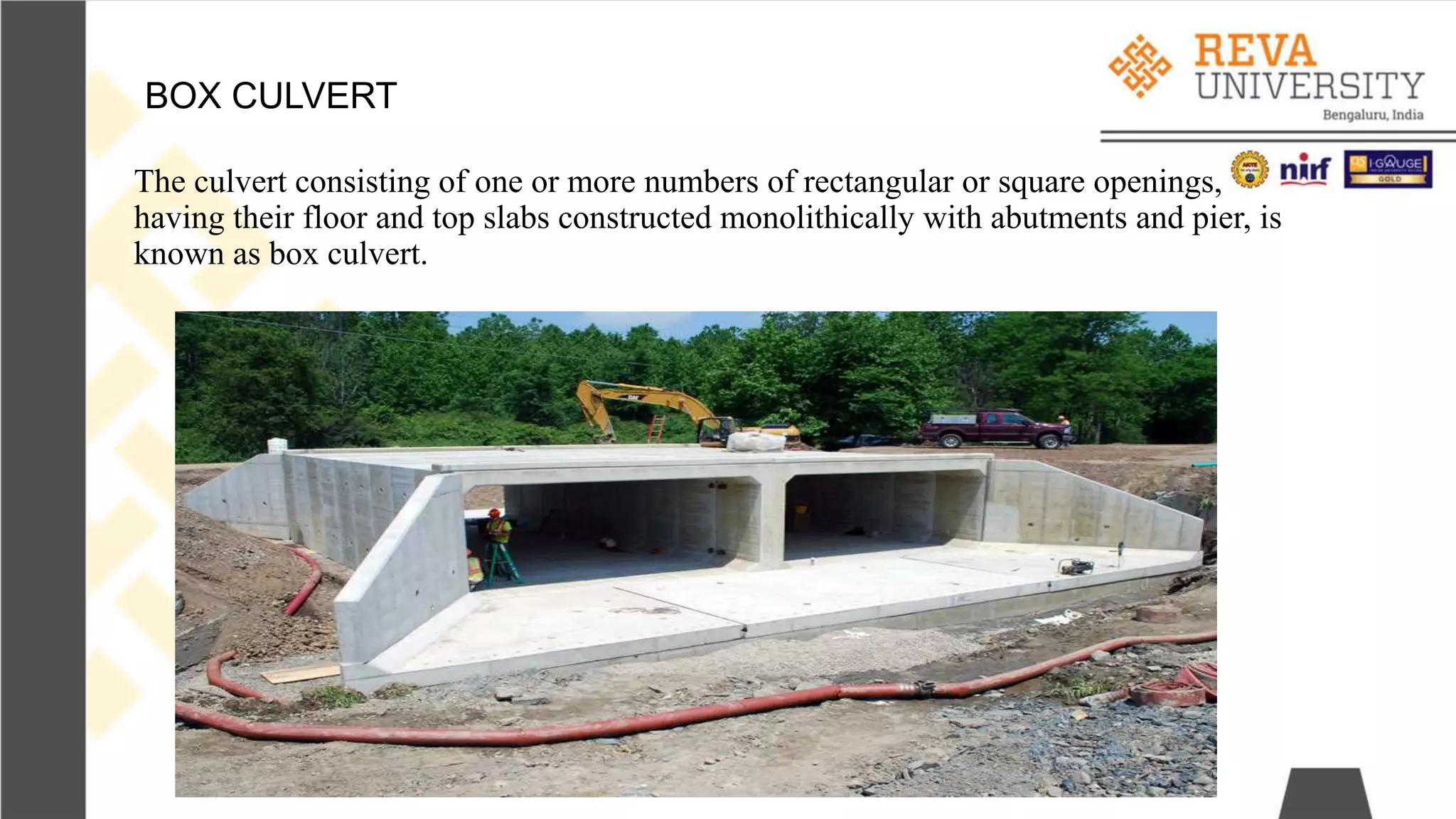

This document discusses box culverts and their components and construction. It begins by defining a culvert as a cross-drainage structure less than 6 meters long. It then describes box culverts, noting they consist of rectangular or square openings constructed monolithically with abutments and piers. Box culverts are typically constructed where soil is soft to distribute load over a wider area. They are made of concrete and can redirect water flow. The document outlines the wet cast and dry cast construction methods and lists the typical components of a box culvert. It also discusses the loads box culverts are subject to and their applications, advantages, and thank you.