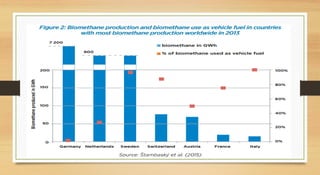

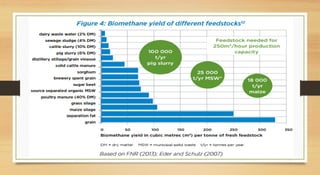

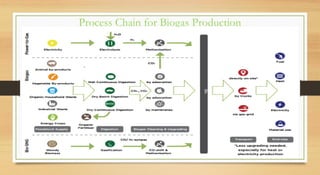

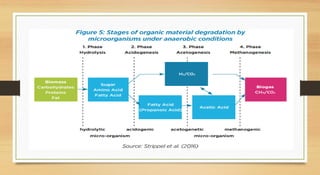

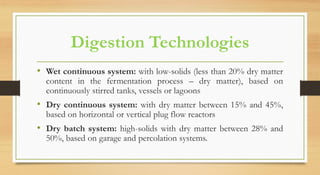

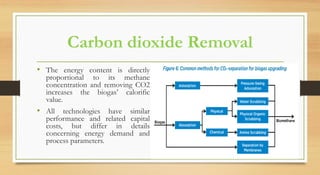

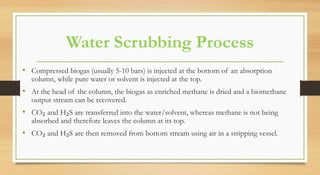

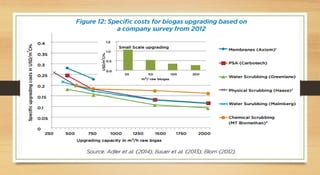

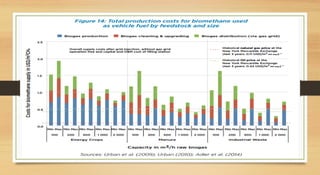

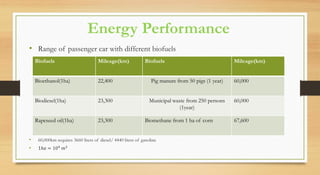

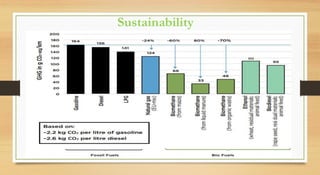

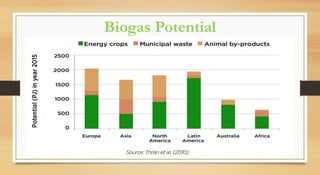

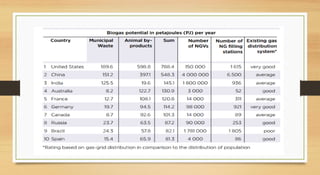

The document provides an extensive overview of biogas as a fuel for road vehicles, detailing its composition, production processes, advantages, and technical requirements for upgrading. It highlights the environmental benefits of biogas, including significant reductions in greenhouse gas emissions compared to fossil fuels, and outlines various challenges and best practice examples from different countries. Additionally, it discusses the economic factors affecting biogas production and use, emphasizing the importance of feedstock selection and processing technologies.