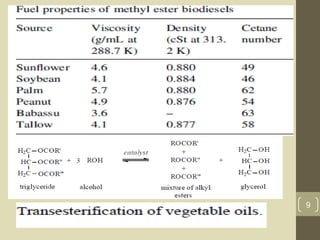

Biodiesel is a cleaner-burning diesel replacement fuel made from vegetable oils and animal fats through a process called trans-esterification. It can be blended with petroleum diesel up to 20% without engine modifications. Biodiesel reduces emissions compared to petroleum diesel, though nitrogen oxide emissions may increase at higher blend levels. It has similar physical properties as diesel, operating in compression-ignition engines.