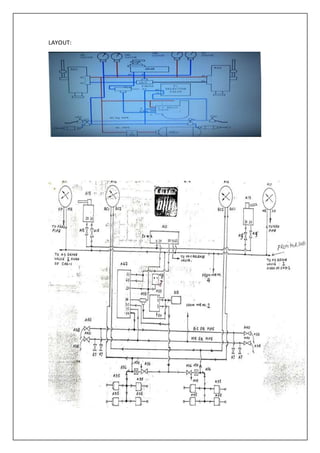

This document provides a summary report on a summer training project at Bharat Heavy Electricals Limited (BHEL) focusing on pneumatic braking systems. It includes an introduction to BHEL, acknowledgments, contents, and sections on locomotive brakes, pneumatic functions, equipment, air systems, and specific brake valves. BHEL is one of the largest engineering companies in India that manufactures power and industrial equipment. The report examines pneumatic braking systems used on locomotives produced at the BHEL facility in Jhansi. It provides technical details on the components, operation, and functions of the pneumatic braking system.