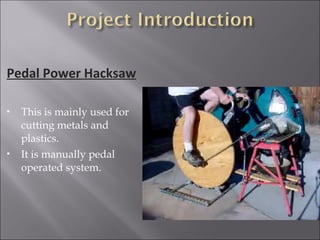

The pedal power hacksaw is a manually operated device designed for cutting metals and plastics, converting pedal motion into linear cutting action. It features several components including a hacksaw blade, pedal arrangement, and a crank and slider mechanism, and can utilize a dynamo to provide lighting in workshops without electricity. Although it is time-saving and energy-efficient compared to hand hacksaws, it is not suitable for heavy production and is entirely dependent on human effort.