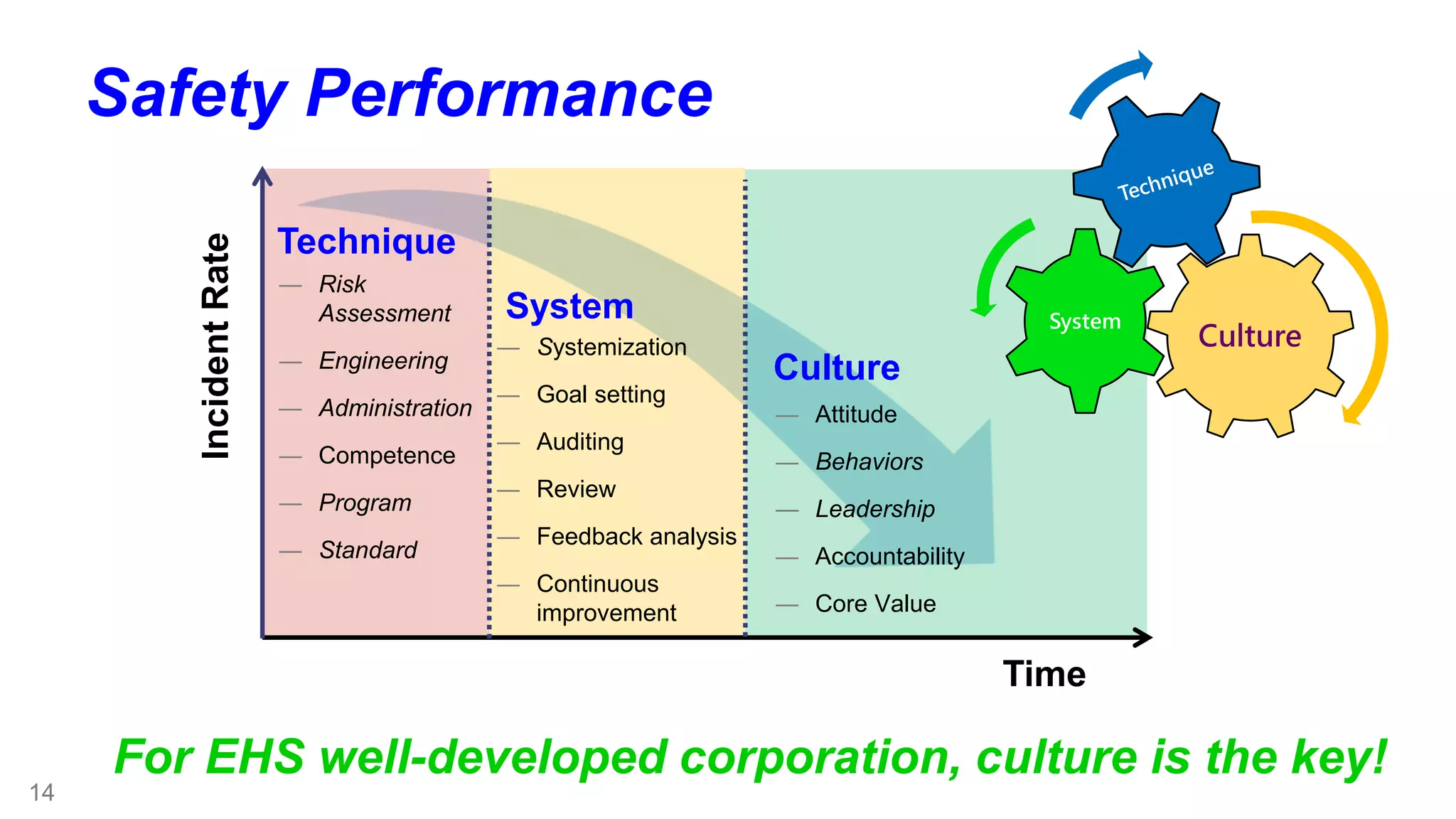

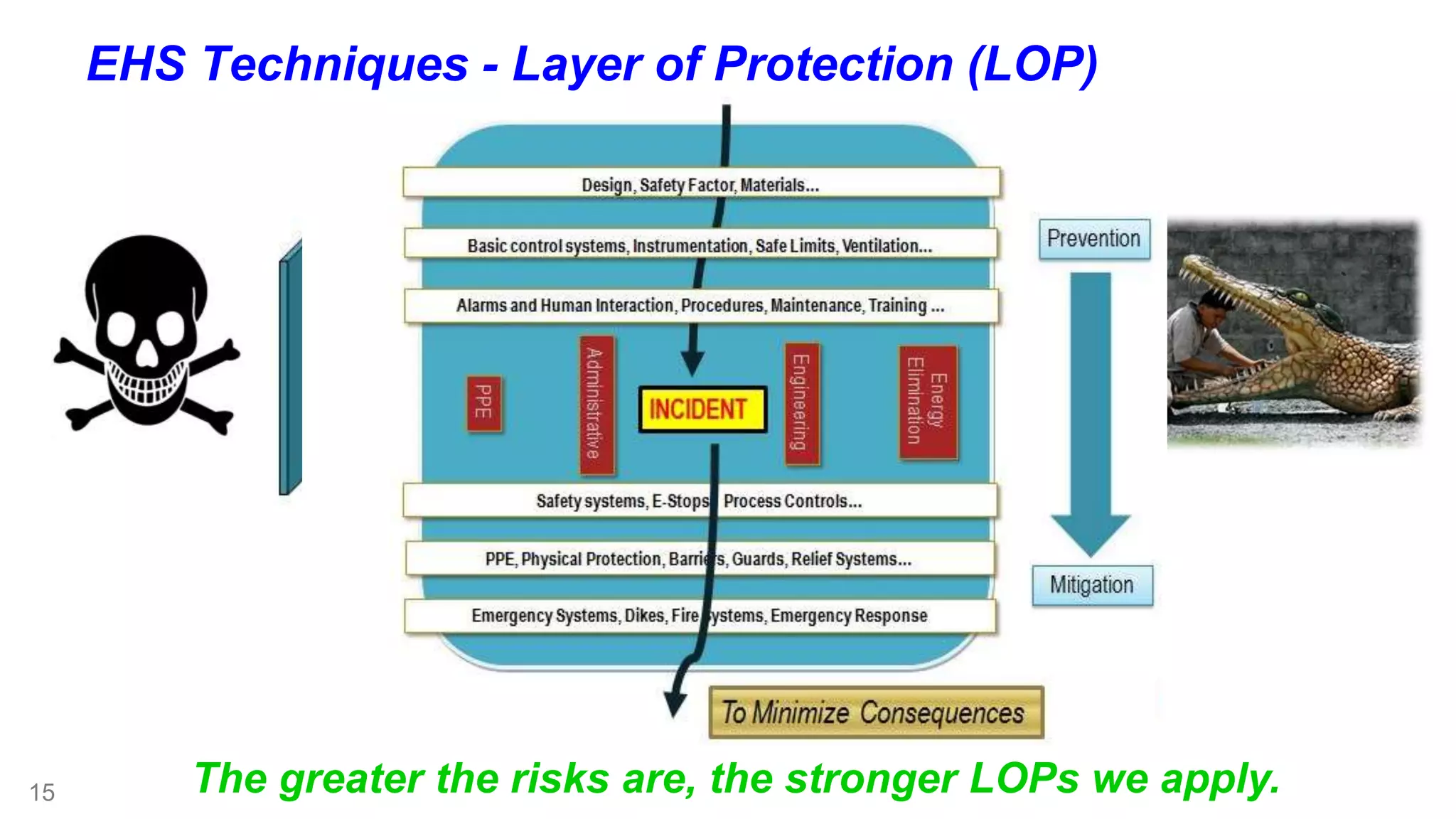

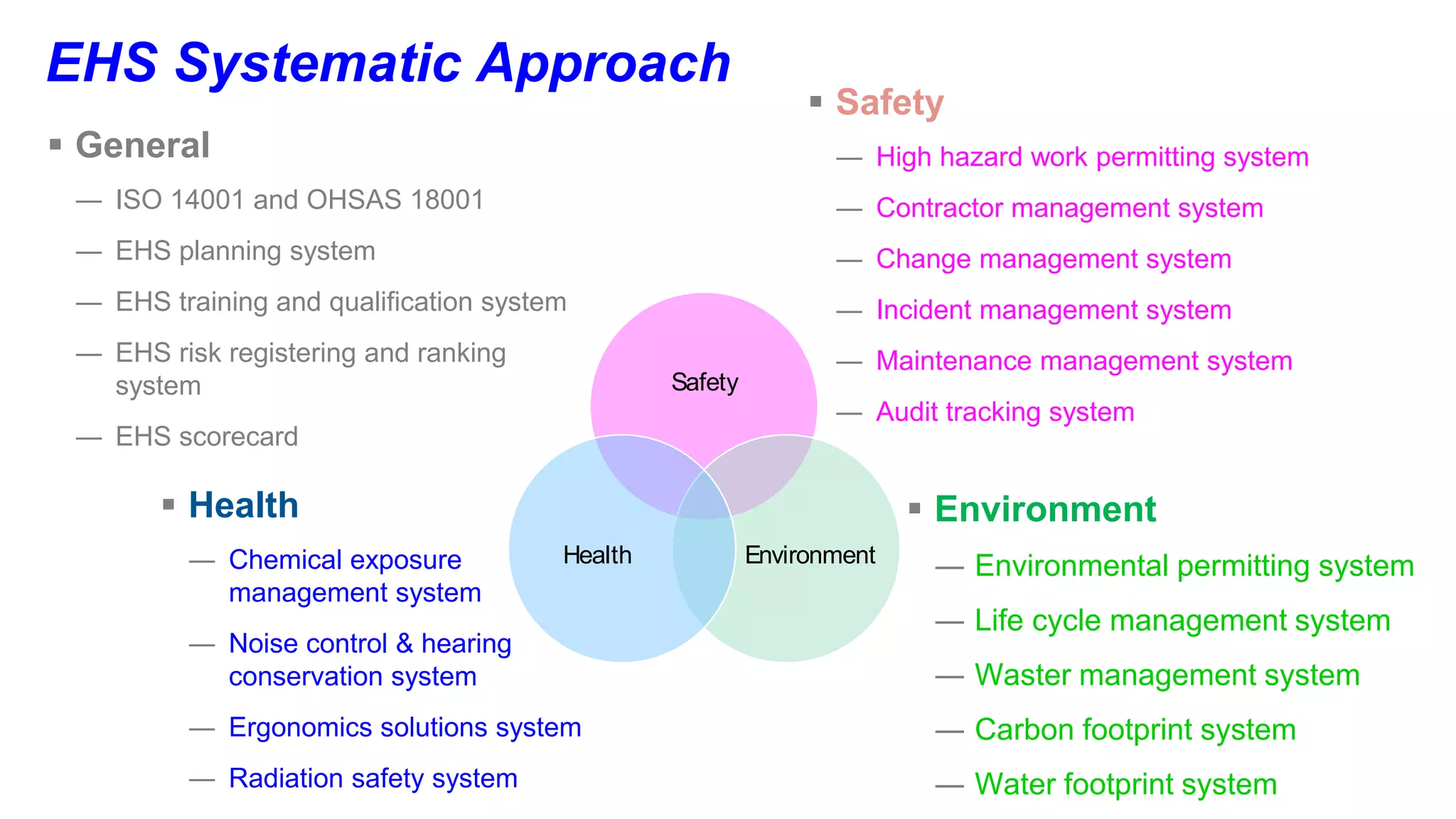

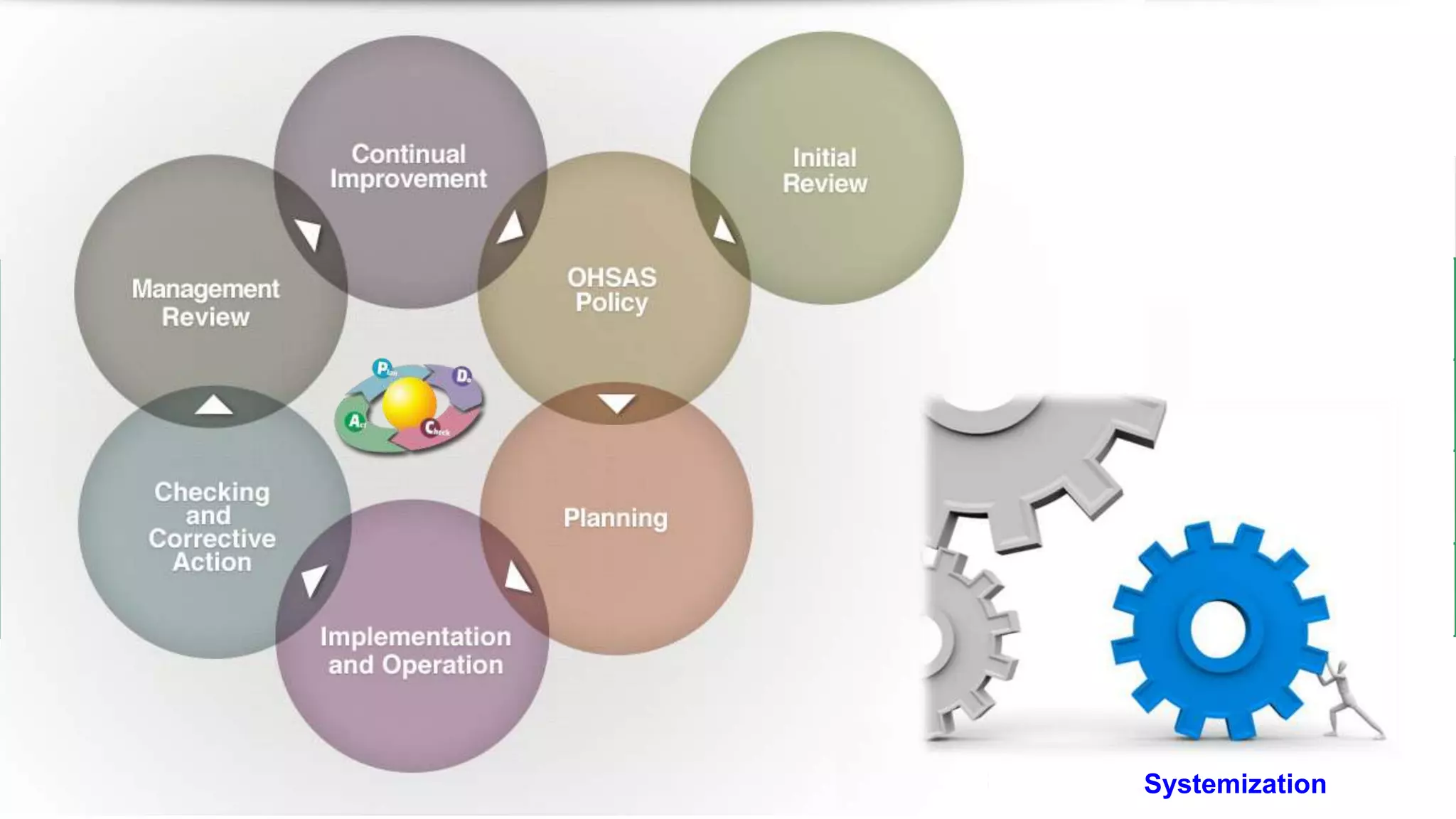

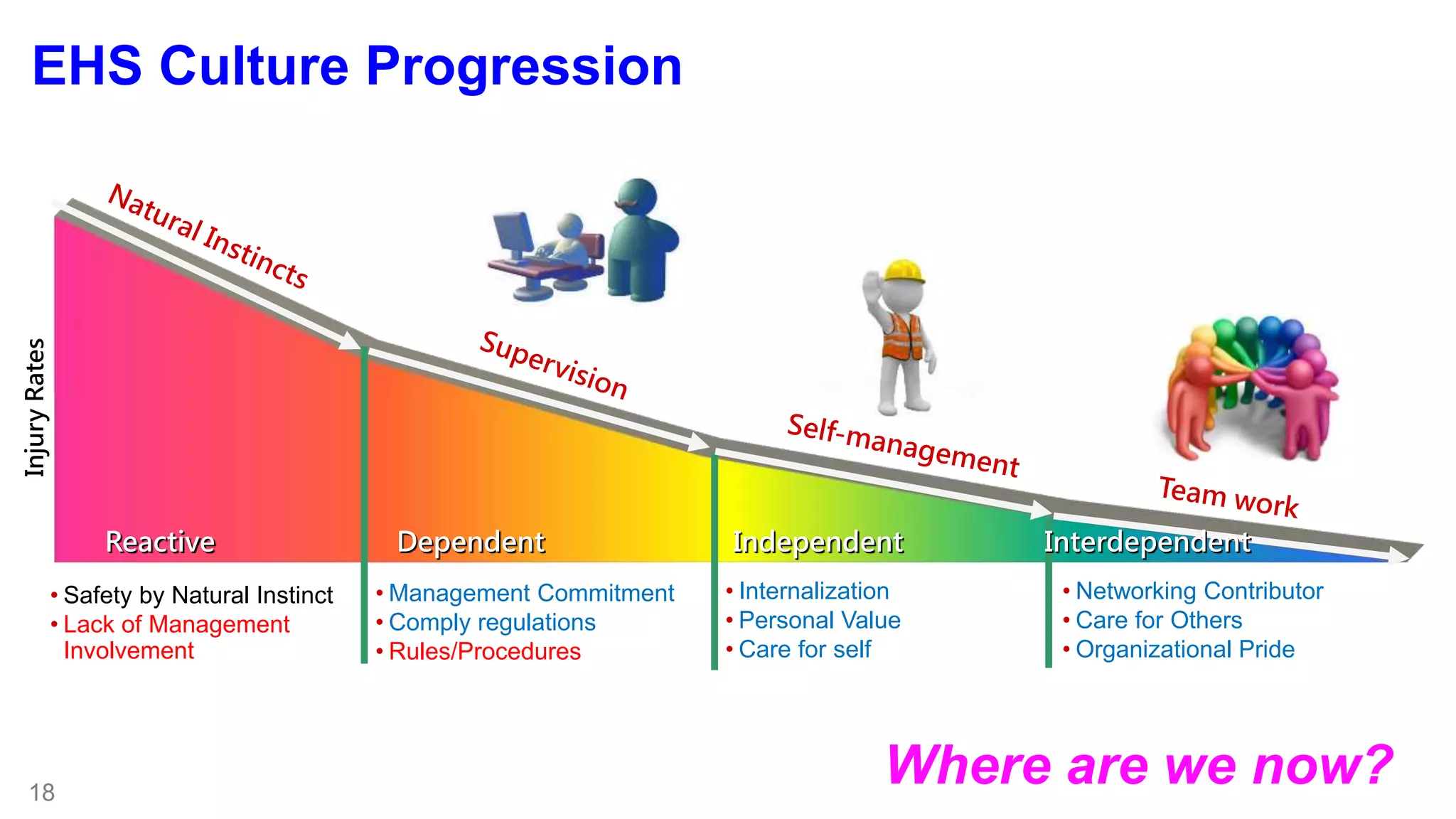

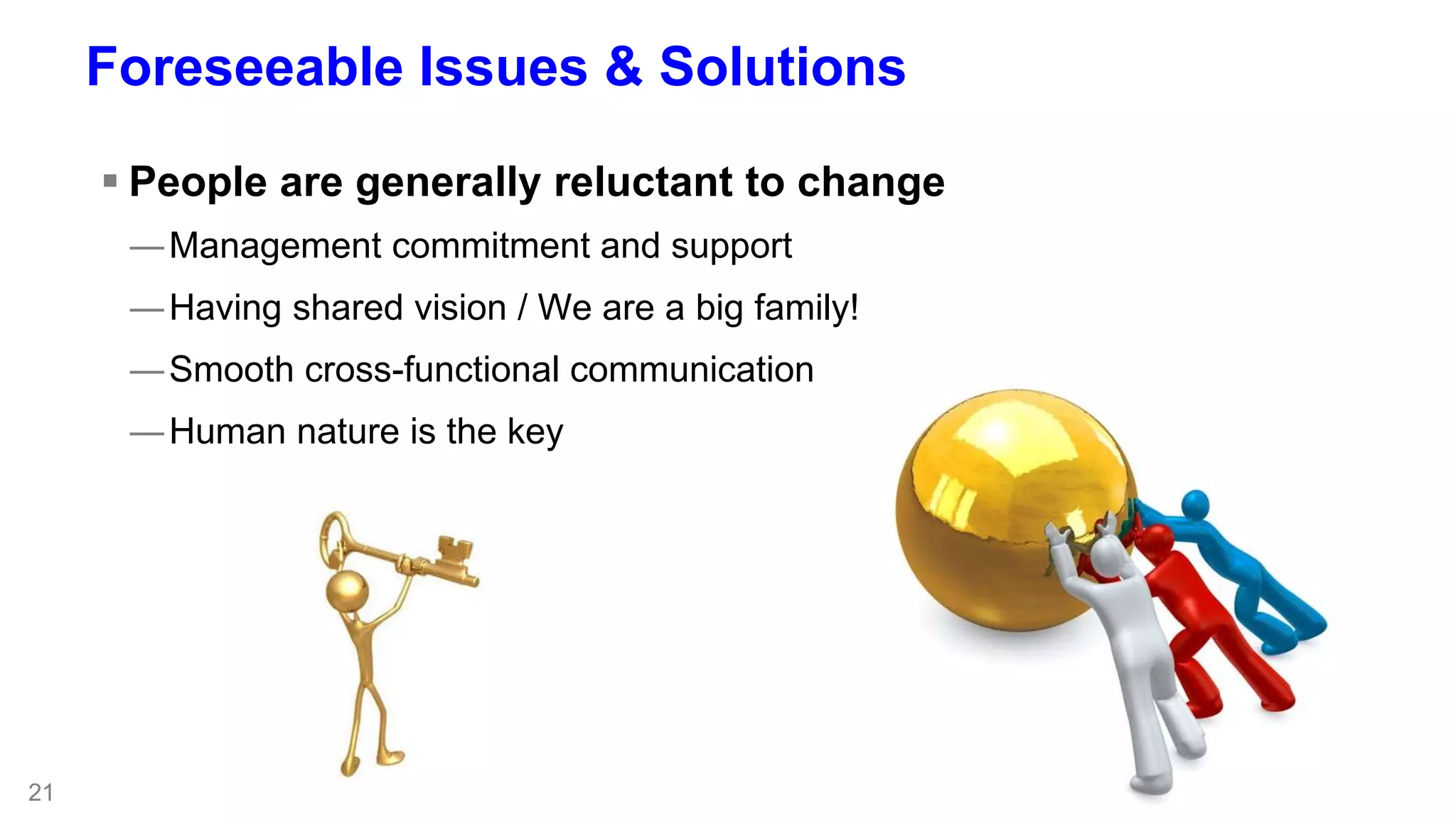

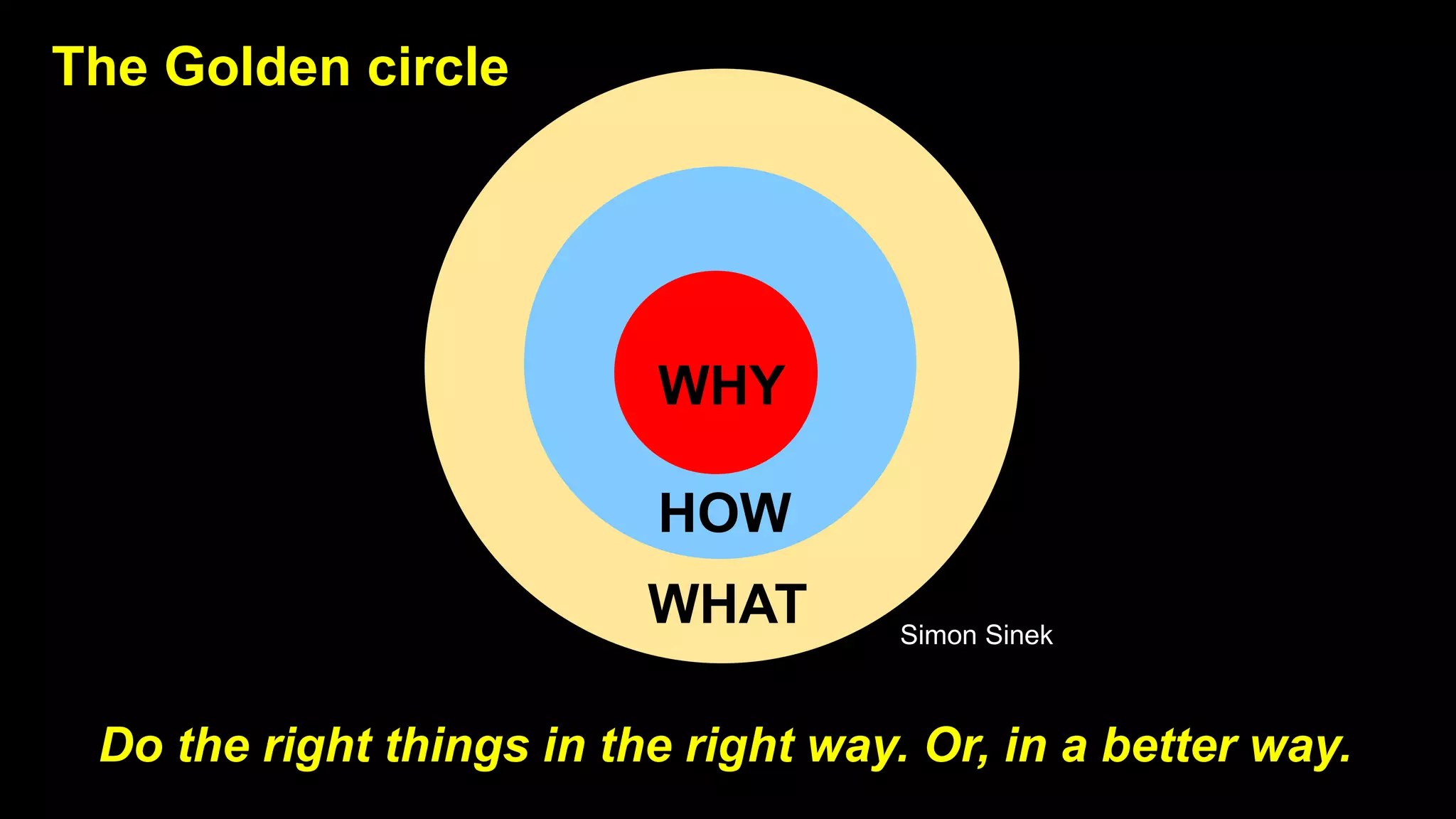

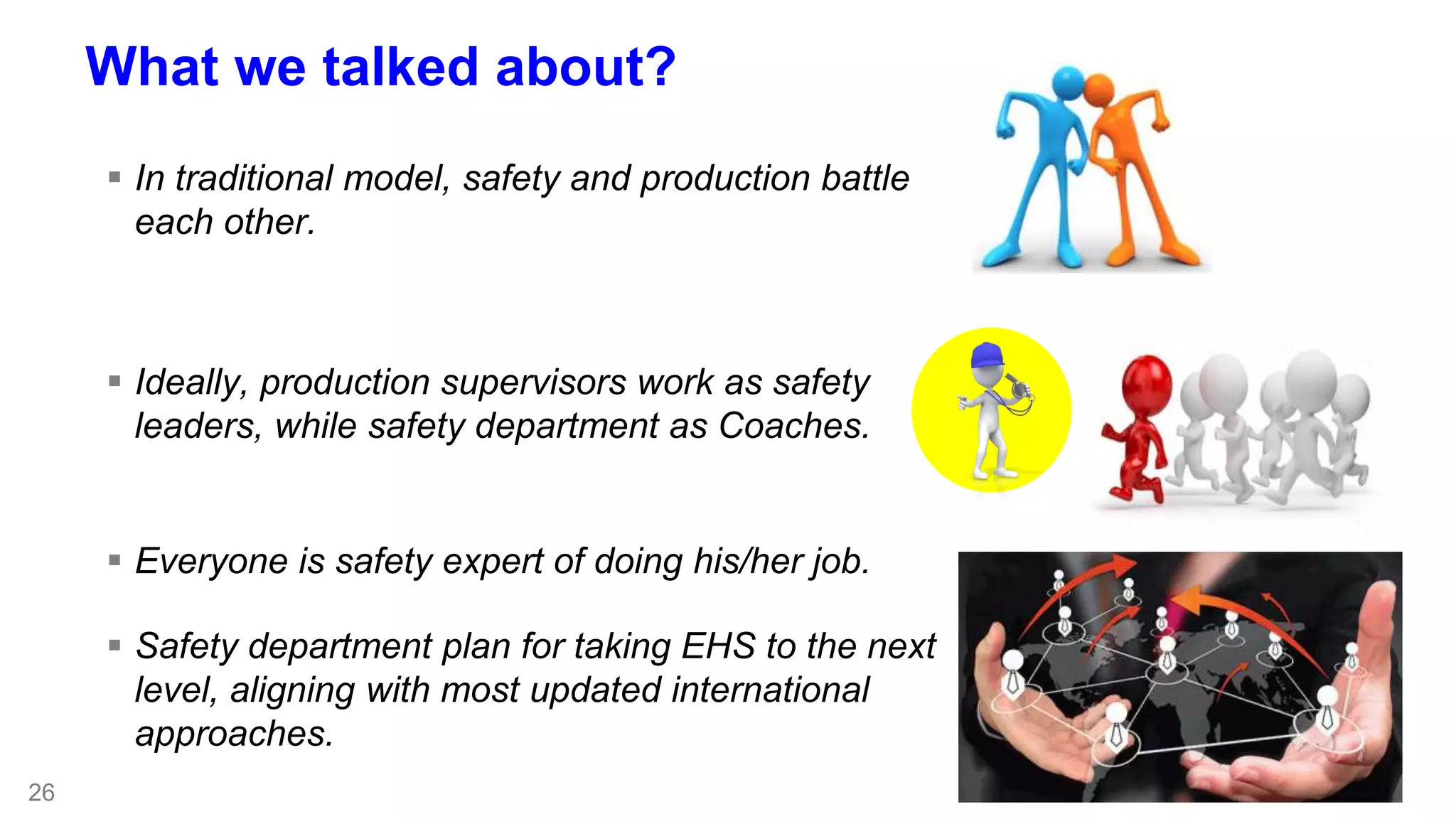

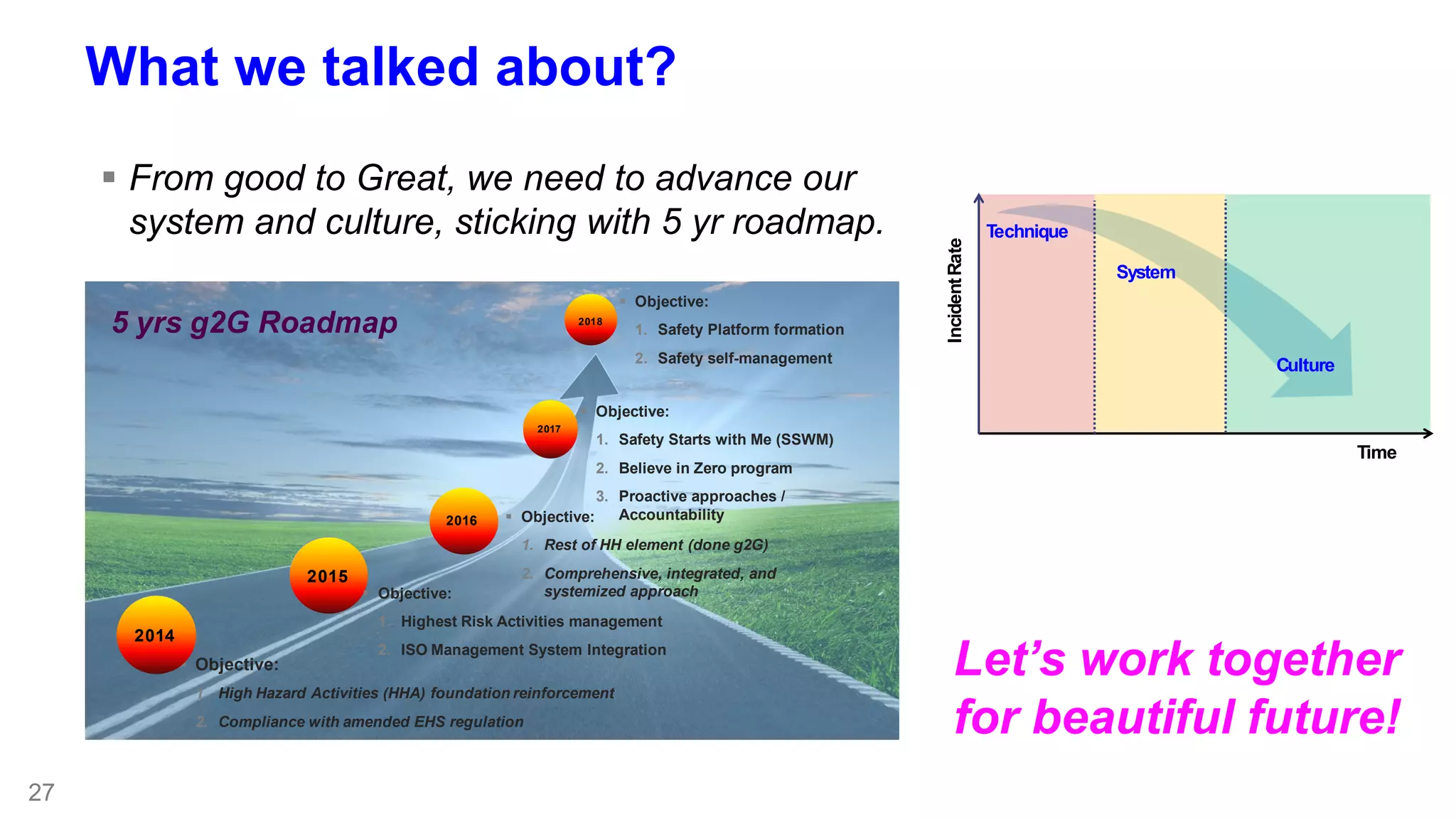

The document outlines a presentation on transforming safety management in organizations, emphasizing a shift from traditional models focusing on control to a coaching culture involving all employees as safety professionals. It proposes a five-year roadmap to integrate safety into corporate culture, align with international standards, and encourage proactive safety leadership among production supervisors. Key elements include redefining roles, enhancing cross-functional communication, and addressing human reluctance to change for a sustainable safety DNA in corporate environments.