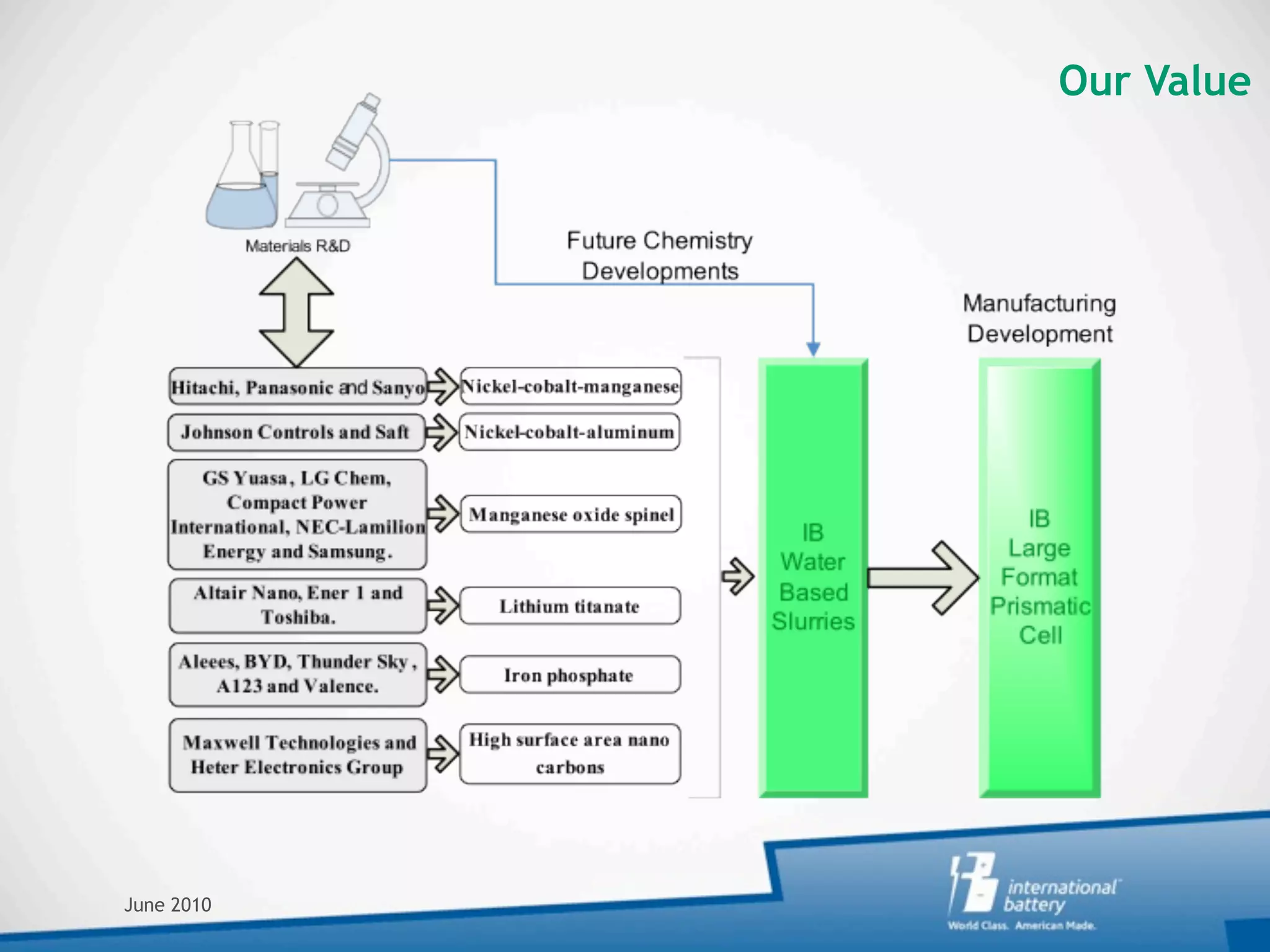

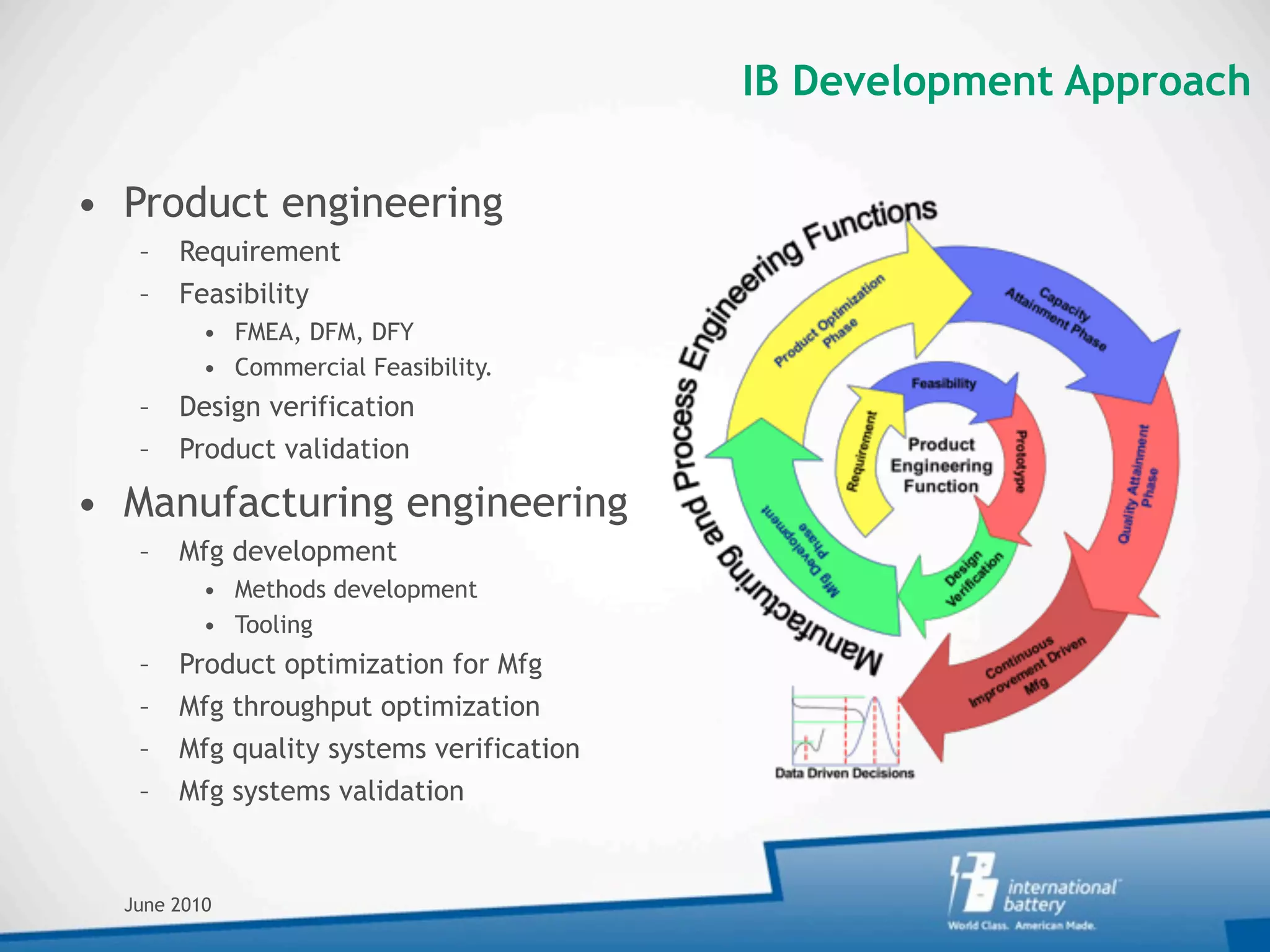

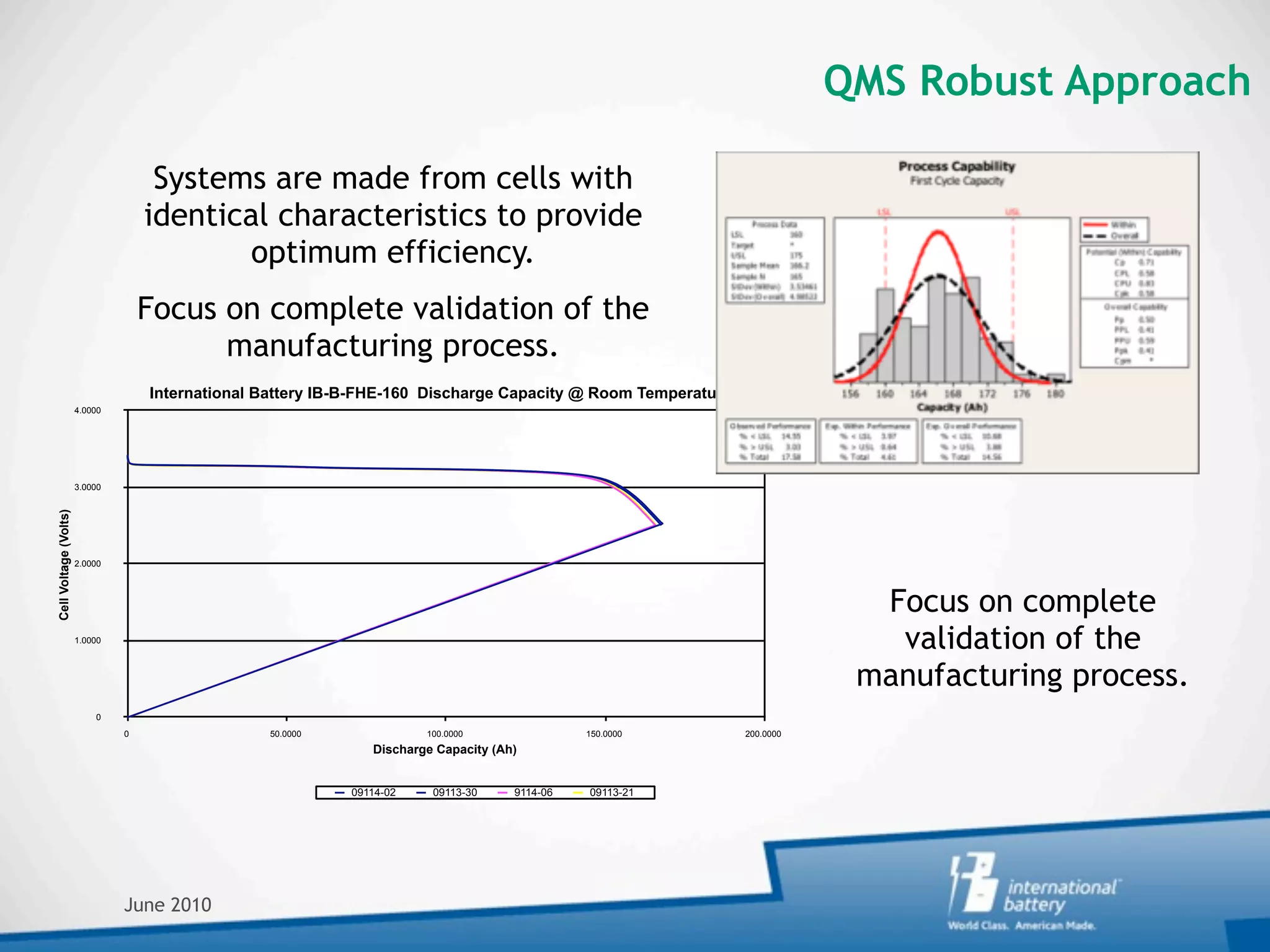

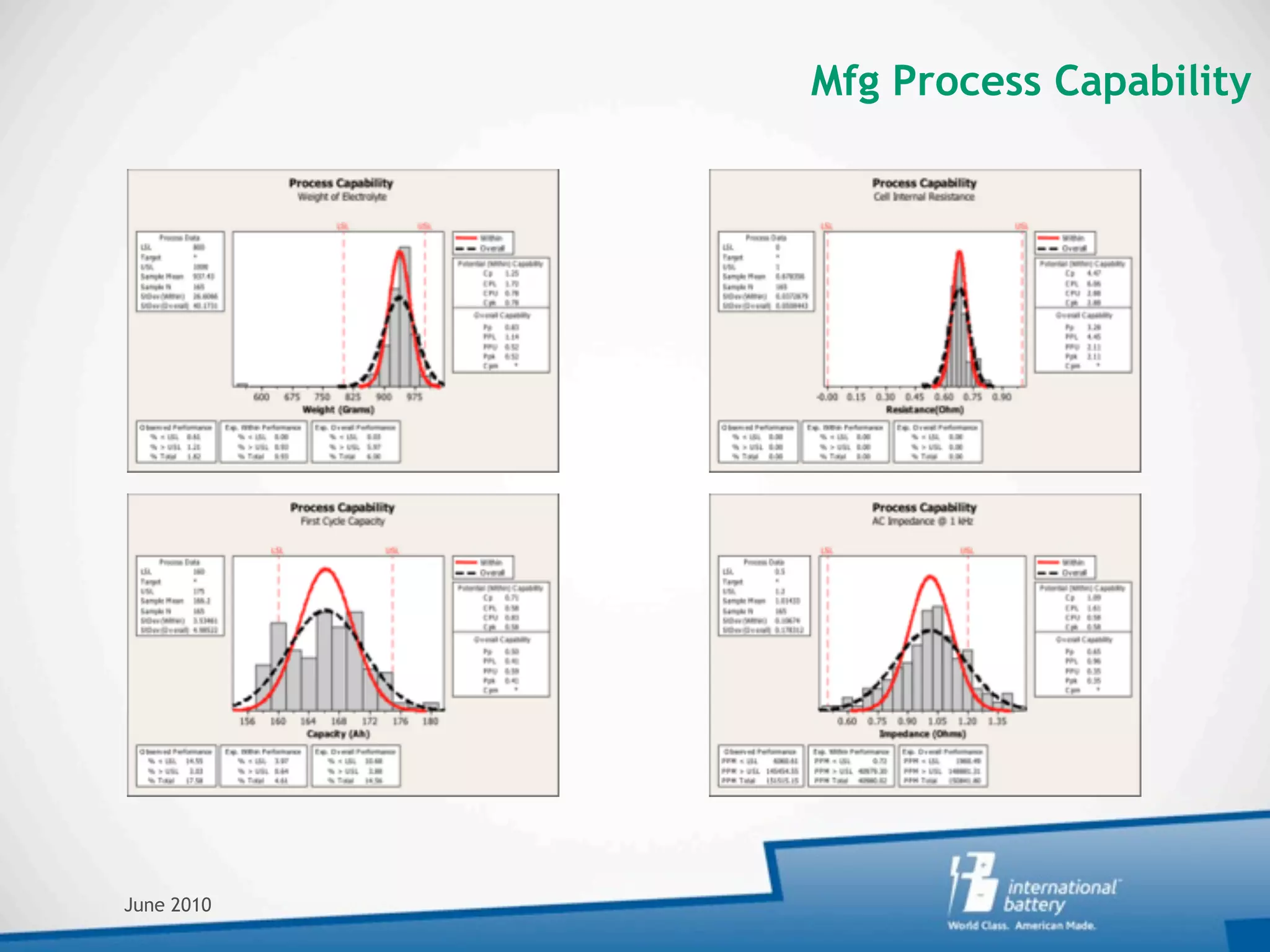

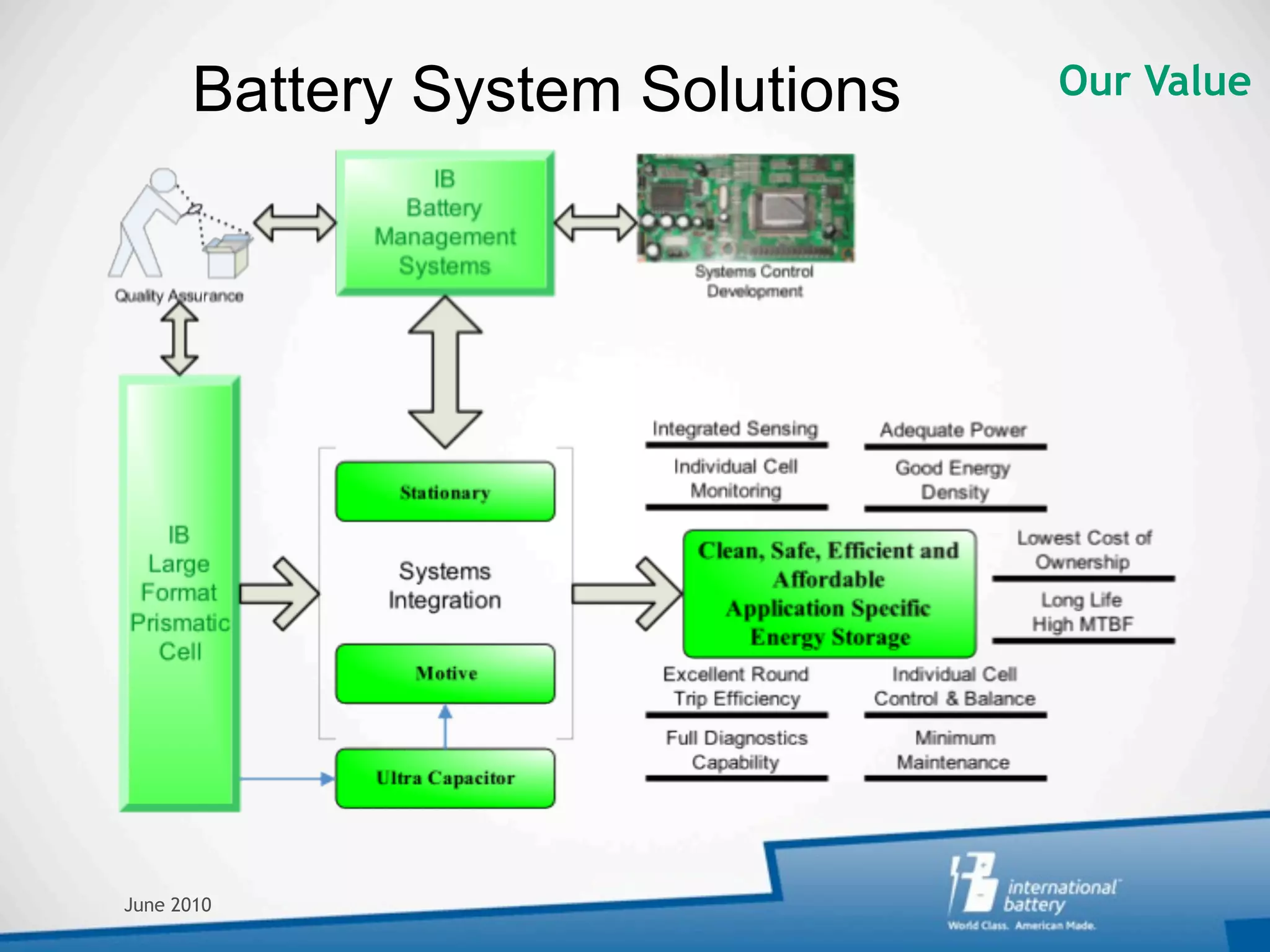

International Battery is developing innovative manufacturing processes for large format lithium ion batteries using water-based slurries. They are implementing lean manufacturing and process validation to achieve efficiency. Their goal is to engage customers in product development and provide robust metrics to determine battery life cycle. International Battery aims to be the first US manufacturer of large lithium ion batteries using chemistry-agnostic and scalable manufacturing processes.