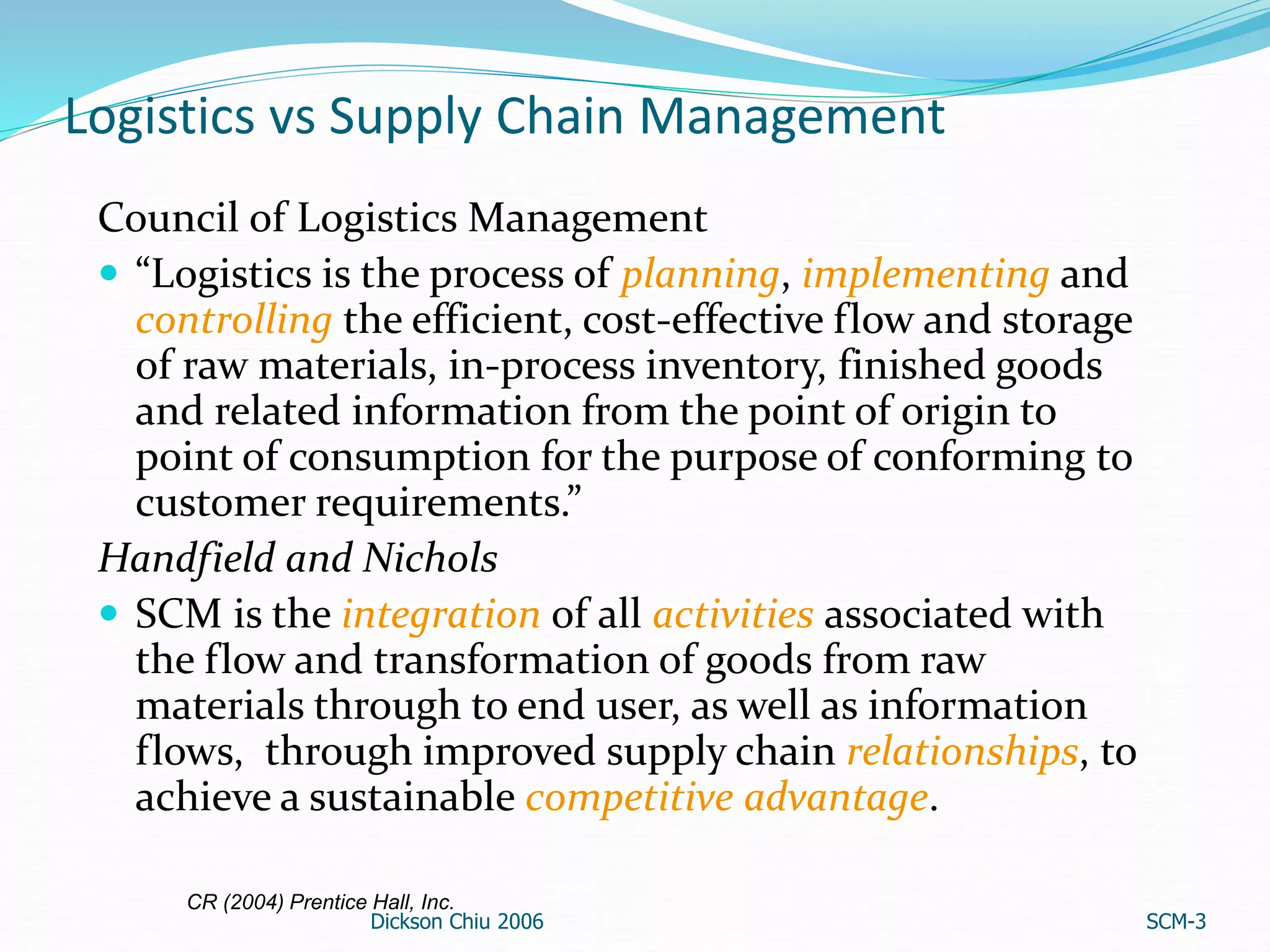

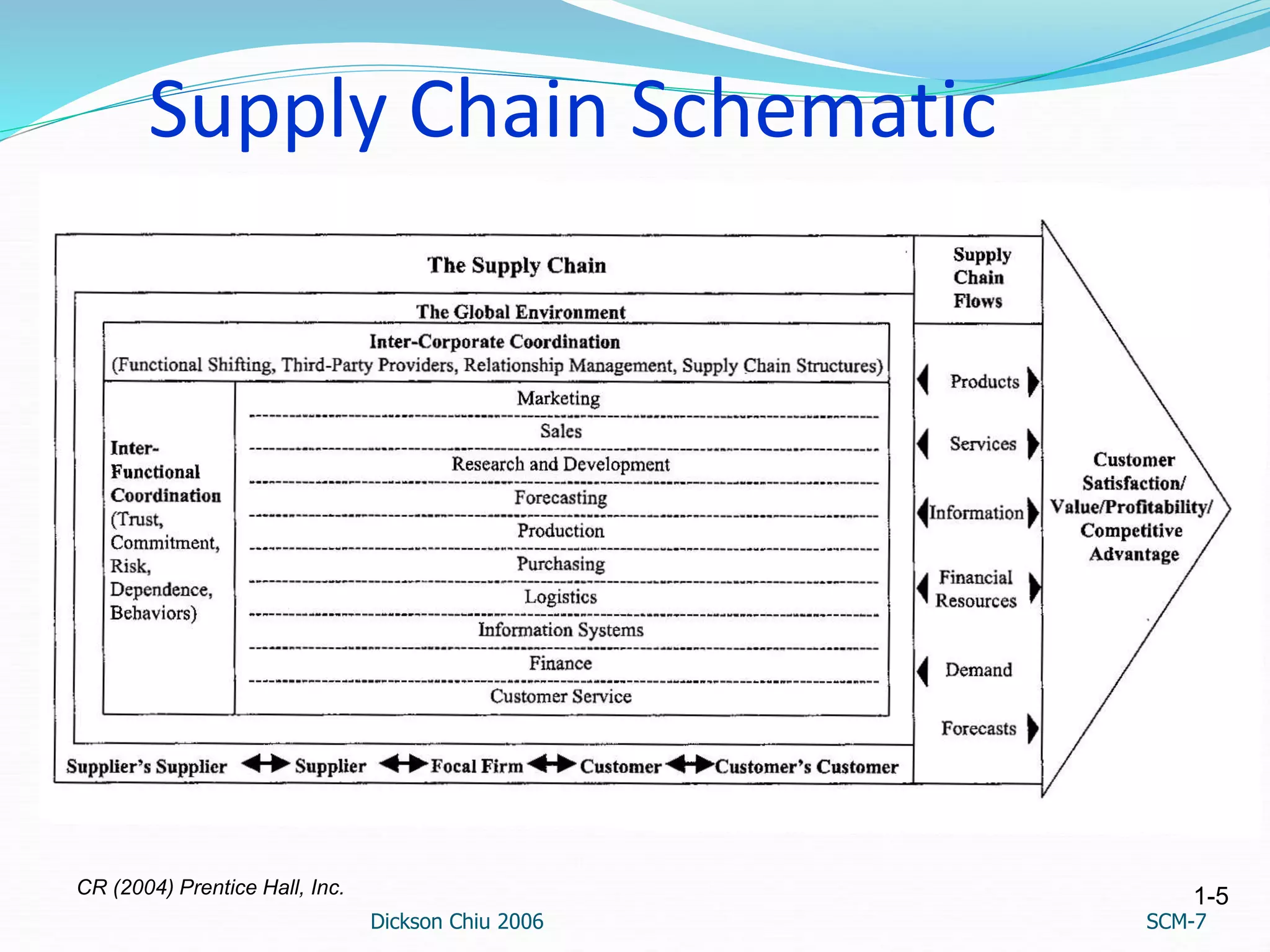

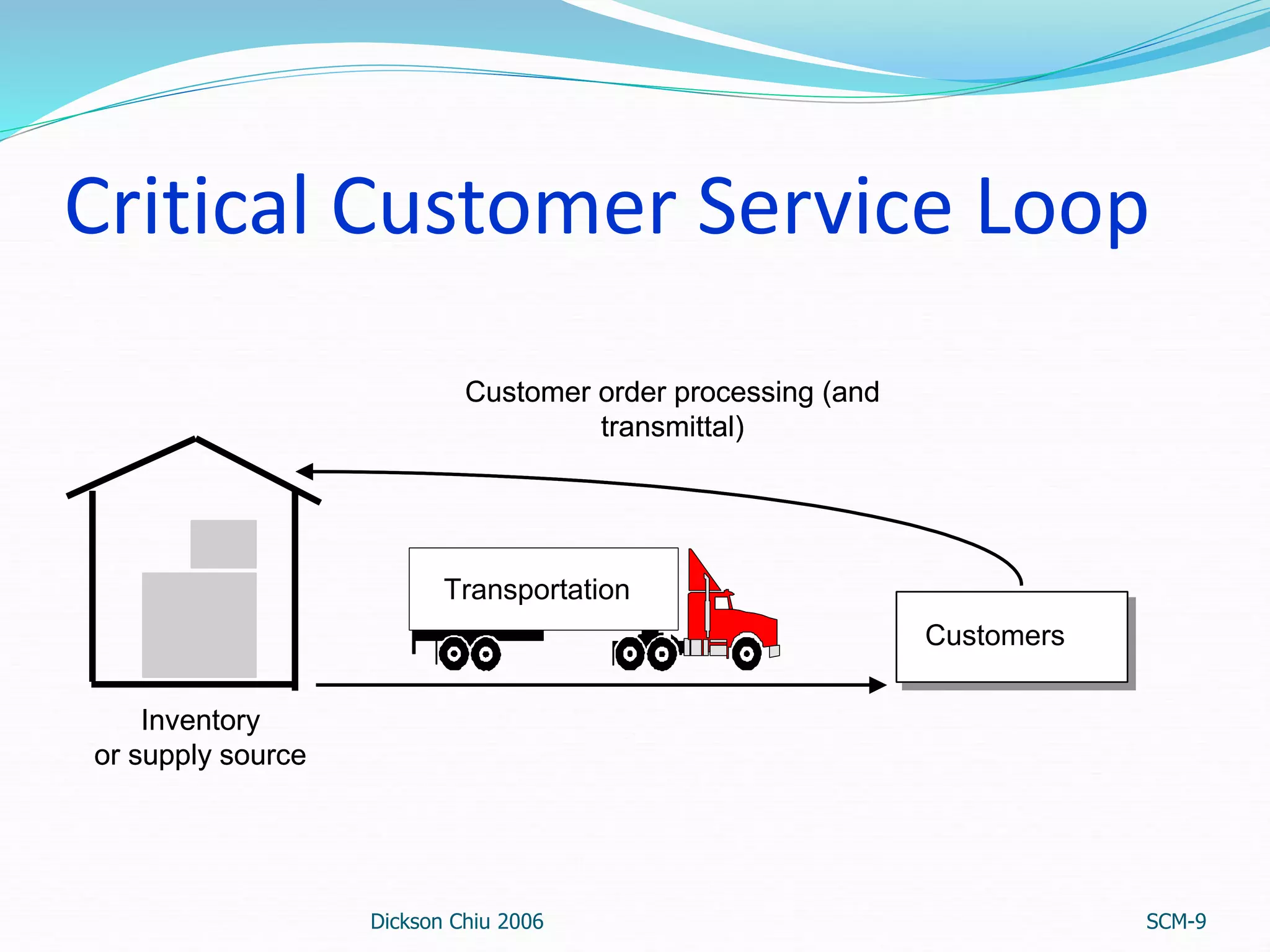

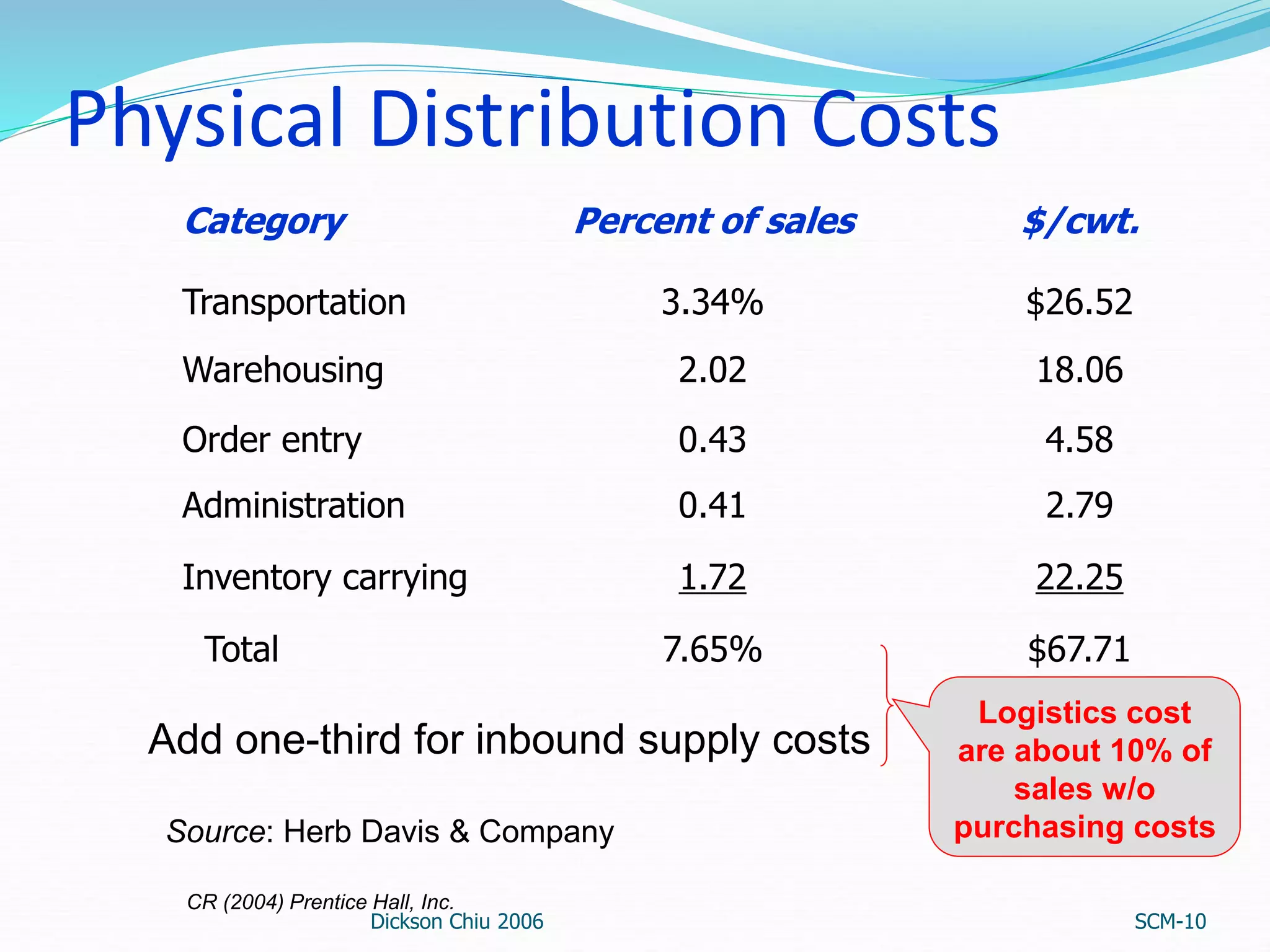

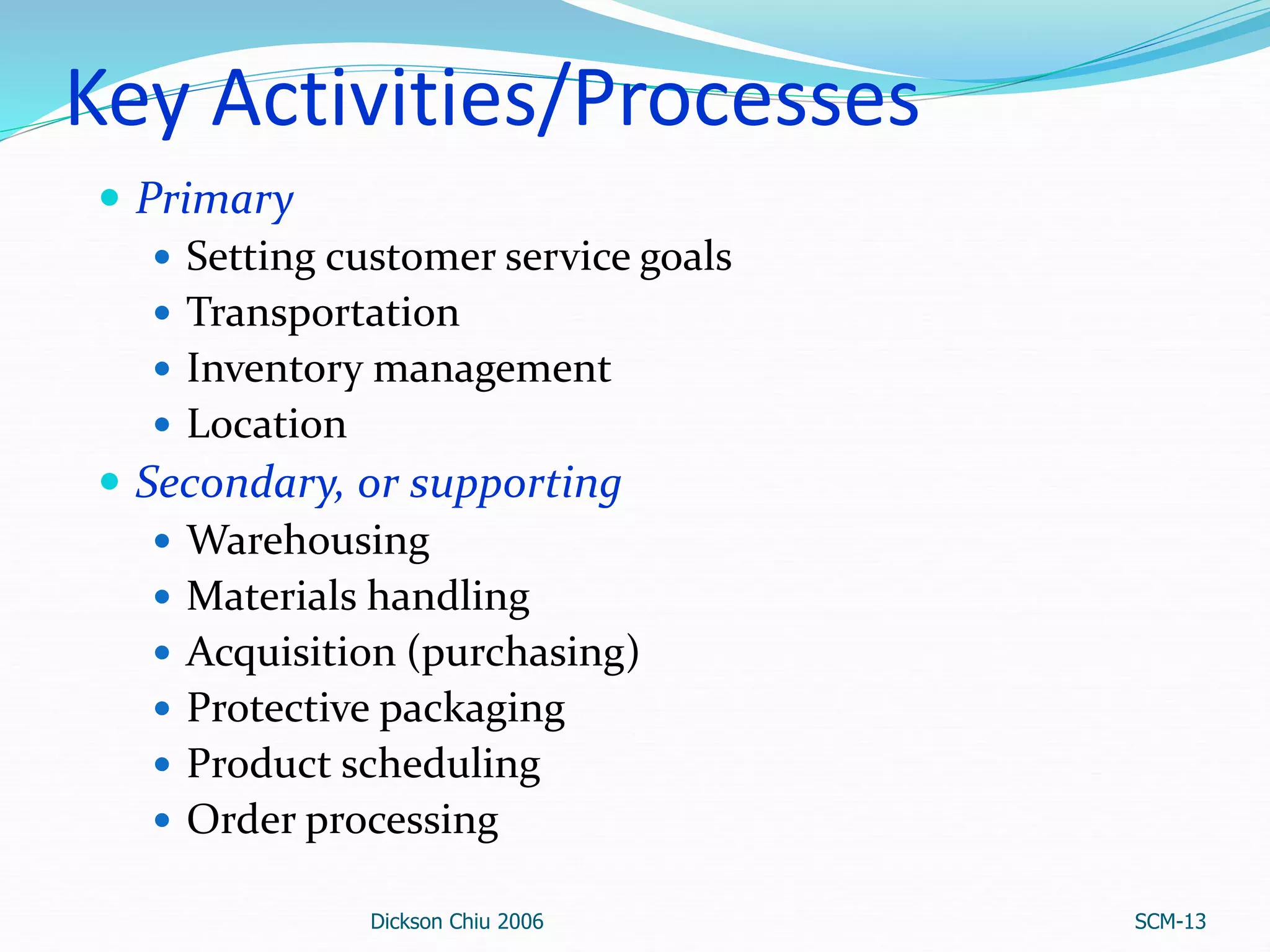

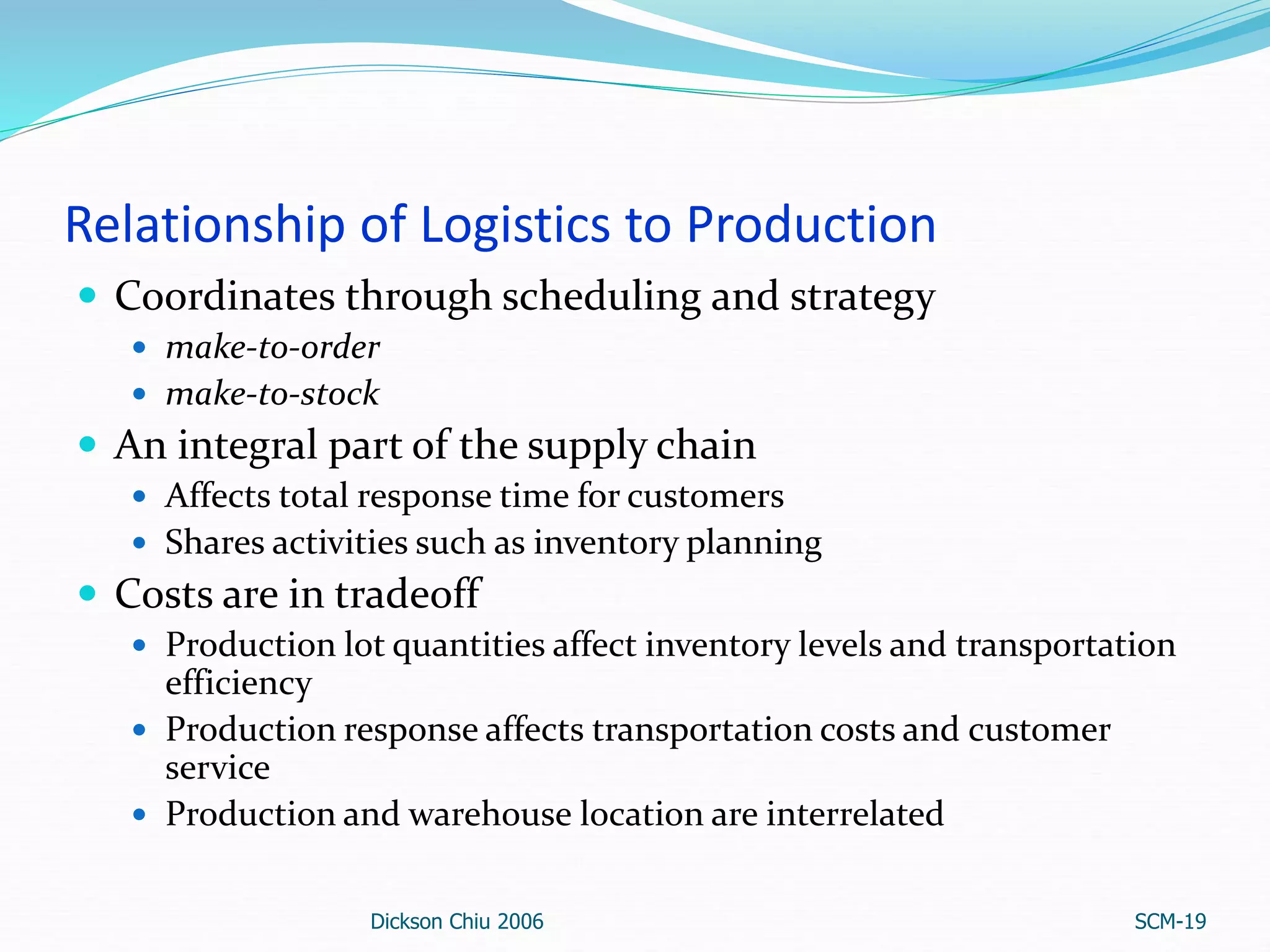

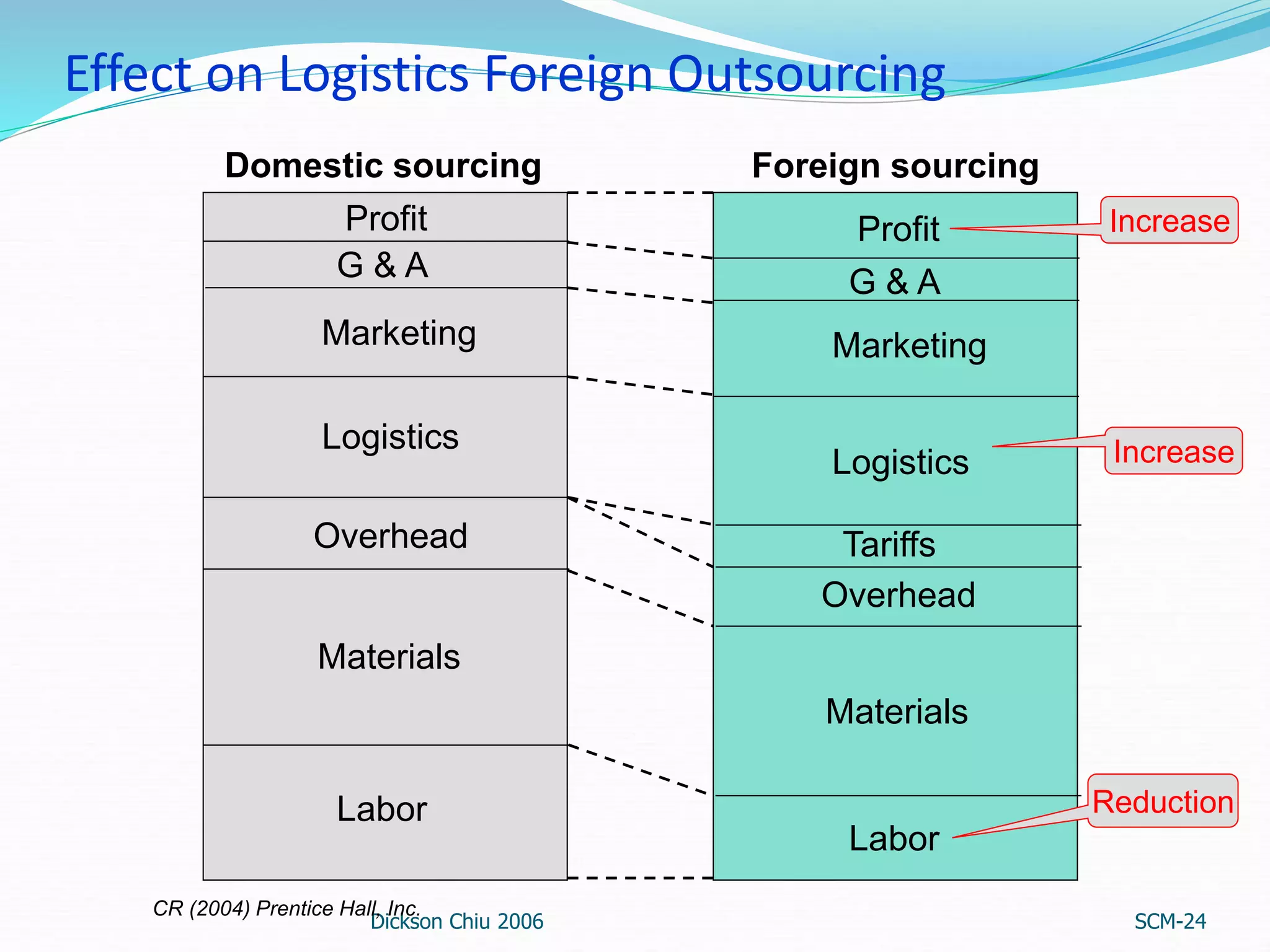

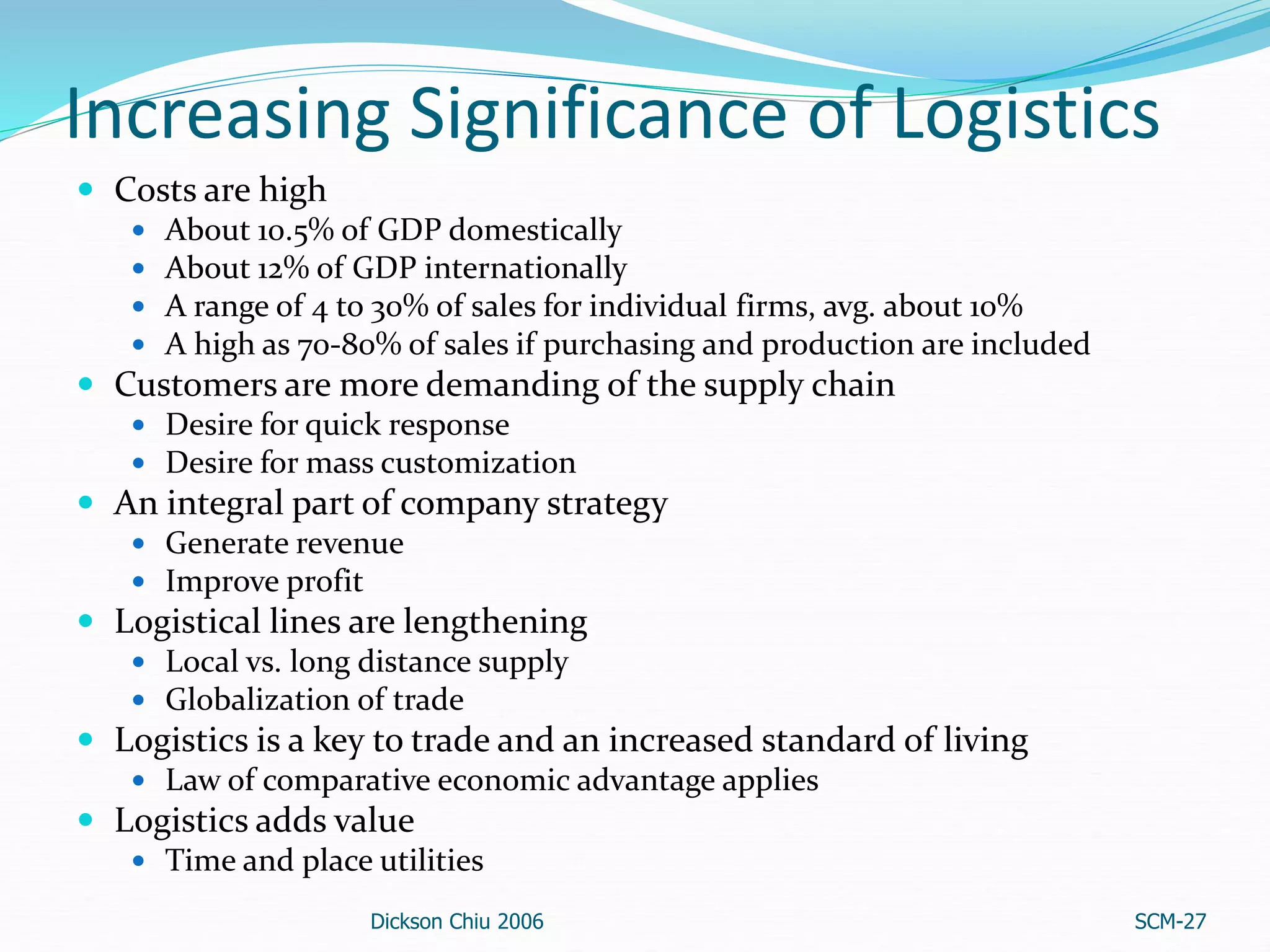

This document provides an overview of supply chain management and logistics. It defines logistics and supply chain management, describing logistics as planning and controlling efficient product flow, and SCM as integrating all activities from raw materials to end user. The document outlines the evolution of SCM from separate functions to integrated management. It also discusses key logistics processes, strategies, and relationships to other functions. Overall, the document presents foundational concepts about logistics and SCM.