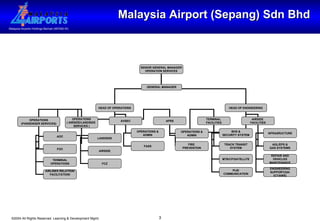

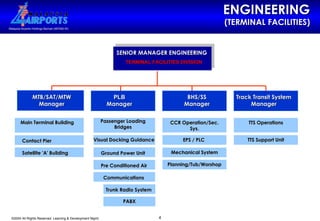

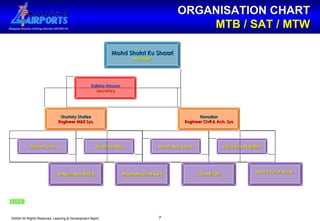

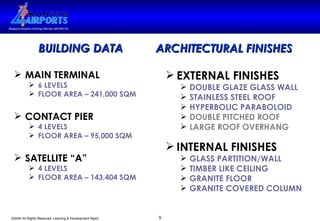

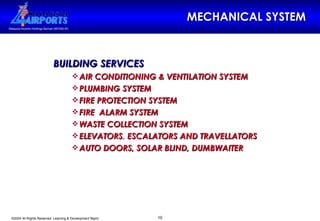

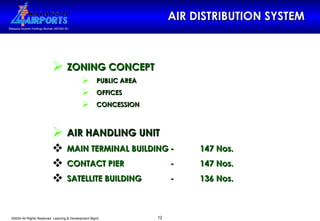

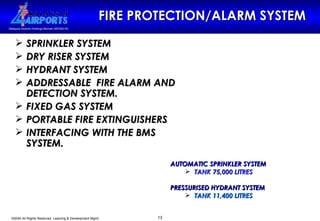

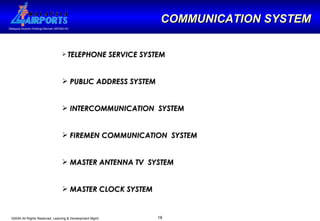

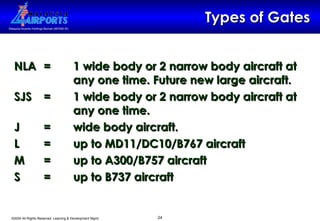

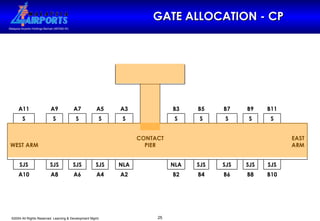

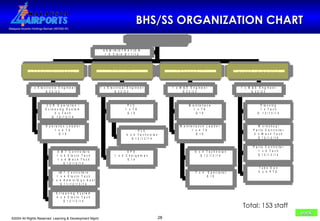

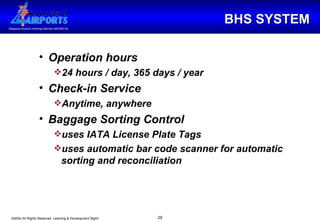

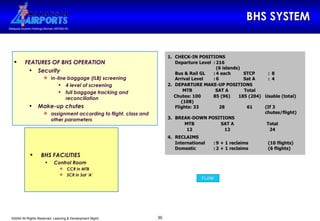

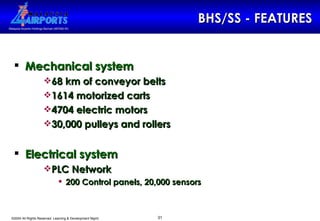

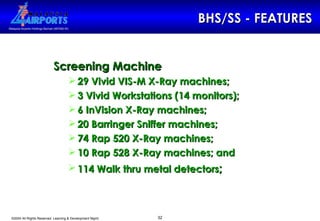

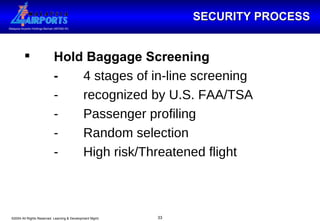

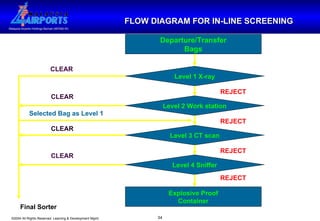

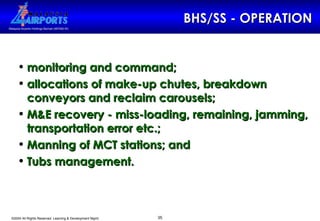

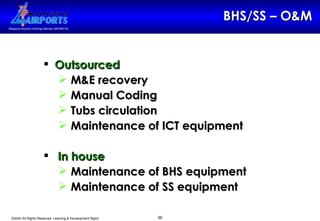

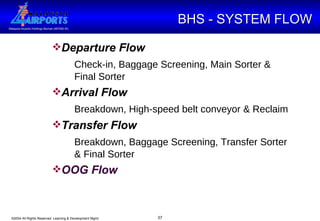

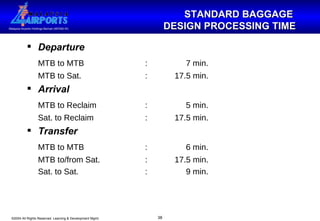

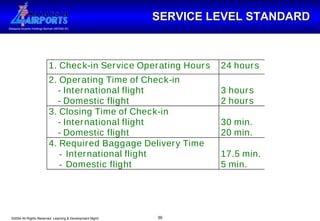

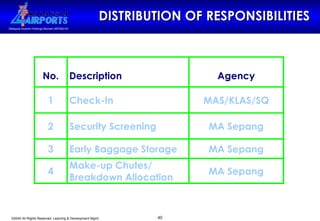

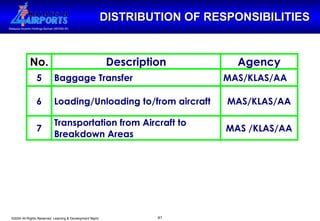

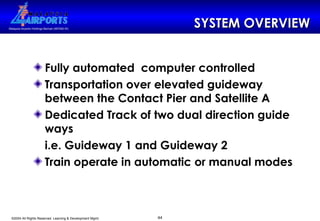

The document describes the facilities and operations of an airport terminal. It outlines the organizational structure and responsibilities of various divisions including terminal facilities, engineering, operations, security systems, baggage handling systems, and track transit systems. It provides details on the maintenance and operations of the terminal buildings, mechanical systems, electrical systems, and other infrastructure.