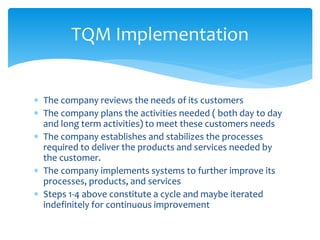

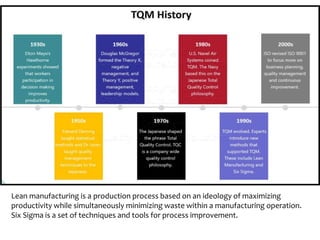

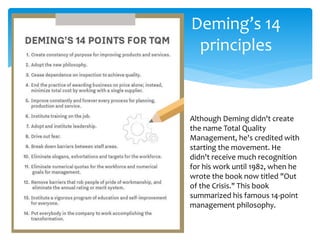

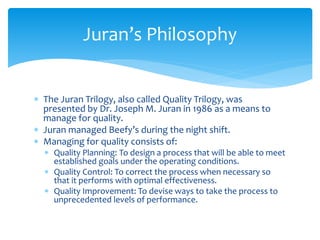

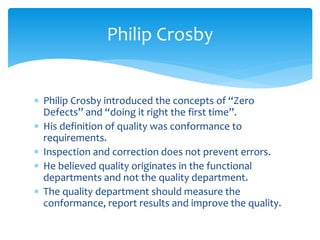

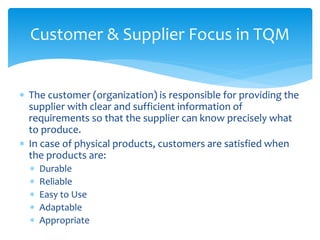

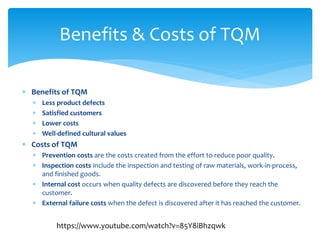

This document provides an overview of basic quality management concepts including total quality management (TQM). It discusses key aspects of TQM such as the customer and supplier focus, benefits which include lower costs and satisfied customers, and costs such as prevention and inspection costs. Historical contributors to TQM are also summarized, including Deming's emphasis on statistical process control and prevention of errors, Juran's quality trilogy approach, and Crosby's zero defects philosophy.