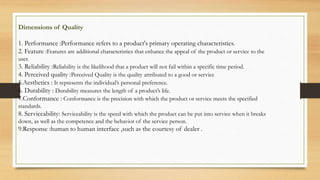

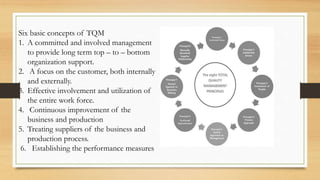

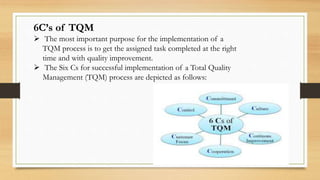

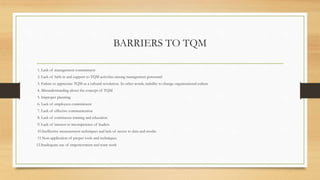

The document outlines the principles and components of quality management systems, emphasizing total quality management (TQM) as a holistic approach to achieving excellence in products and services through continuous improvement and customer satisfaction. Key concepts include customer focus, leadership, and the importance of involving all employees in the quality process. TQM has evolved over time, influenced by historical figures and events, and can encounter barriers such as lack of management commitment and inadequate planning.