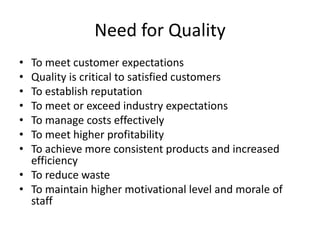

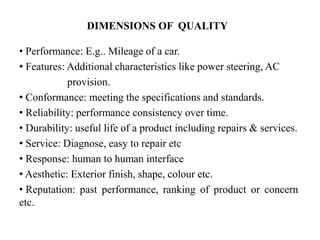

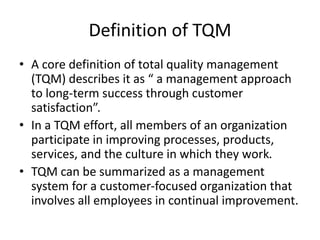

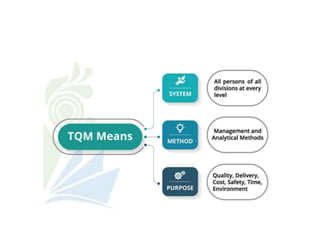

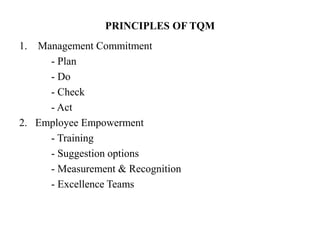

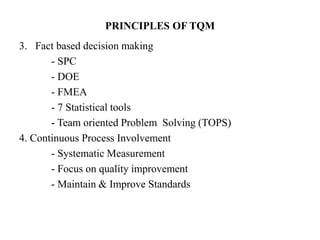

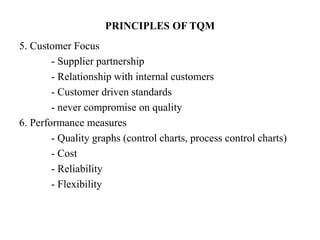

This document provides an overview of the course 20ME505-TOTAL QUALITY MANAGEMENT. It outlines the course objectives, units to be covered, outcomes, textbooks and references. The key concepts that will be learned include an introduction to total quality management (TQM), TQM principles, statistical process control, TQM tools, and quality systems. TQM aims to achieve long-term success through customer satisfaction using a management approach where all employees participate in continual improvement of processes, products, services, and culture.