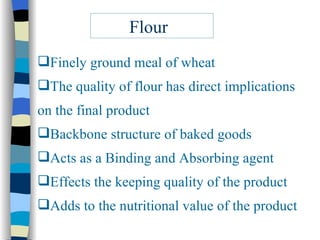

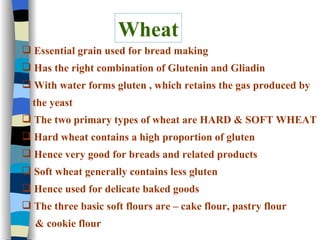

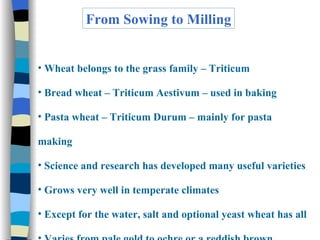

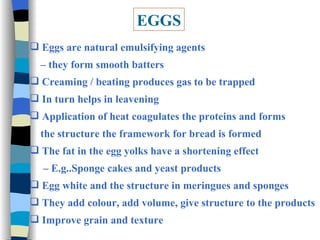

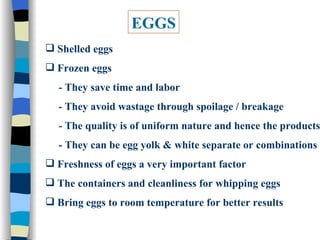

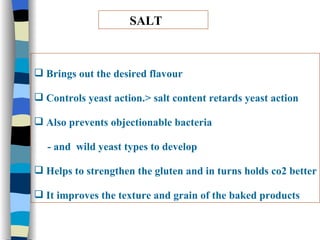

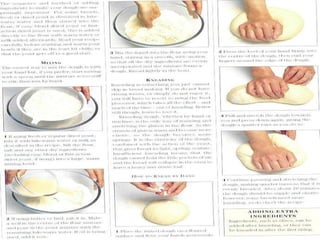

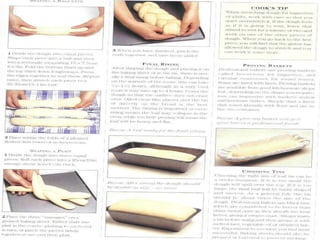

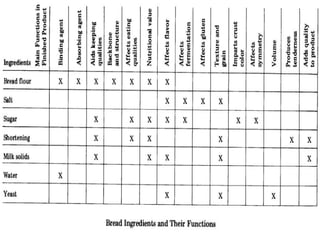

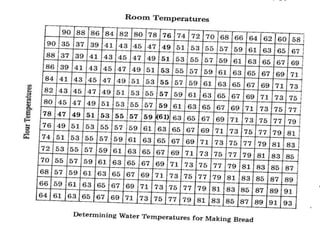

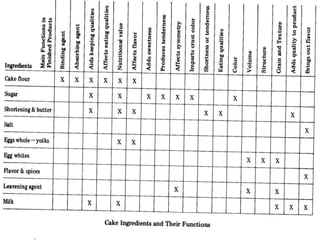

The document discusses various ingredients and processes used in baking. It describes flour as the backbone of baked goods and wheat as the primary grain used. It explains the milling process that separates wheat into bran, germ, and flour kernel. Different types of flour are produced depending on whether the bran and germ are kept in or removed. The document also outlines the roles of other ingredients like eggs, salt, milk, yeast, and chemical leaveners in bread making and how temperature and fermentation impact the dough.