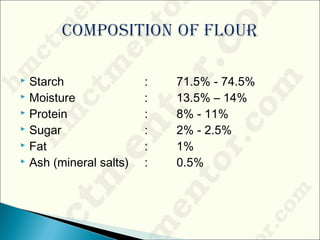

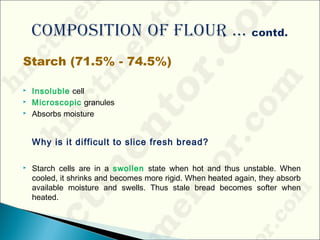

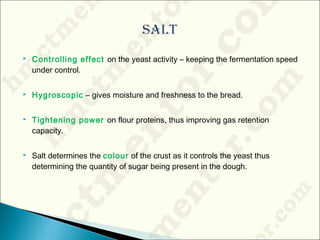

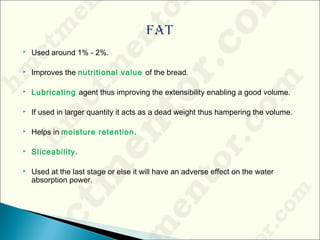

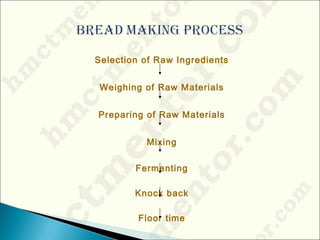

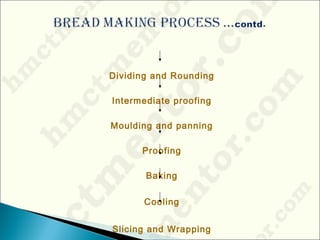

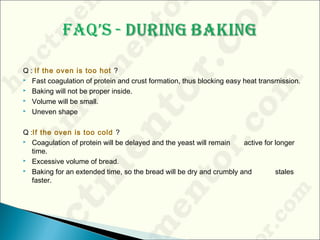

This document provides information on the composition and properties of bread. It states that starch makes up 71.5-74.5% of bread, while moisture is 13.5-14%. Protein (8-11%), sugar (2-2.5%), fat (1%), and ash (0.5%) are also components. Starch granules absorb moisture and cause bread to stiffen when cooled. High moisture reduces bread yield. Proteins provide structure and allow gas retention. Various production steps are outlined, including fermentation, shaping, proofing, and baking. Different bread-making methods such as straight dough, salt delay, and sponge and dough are also summarized.