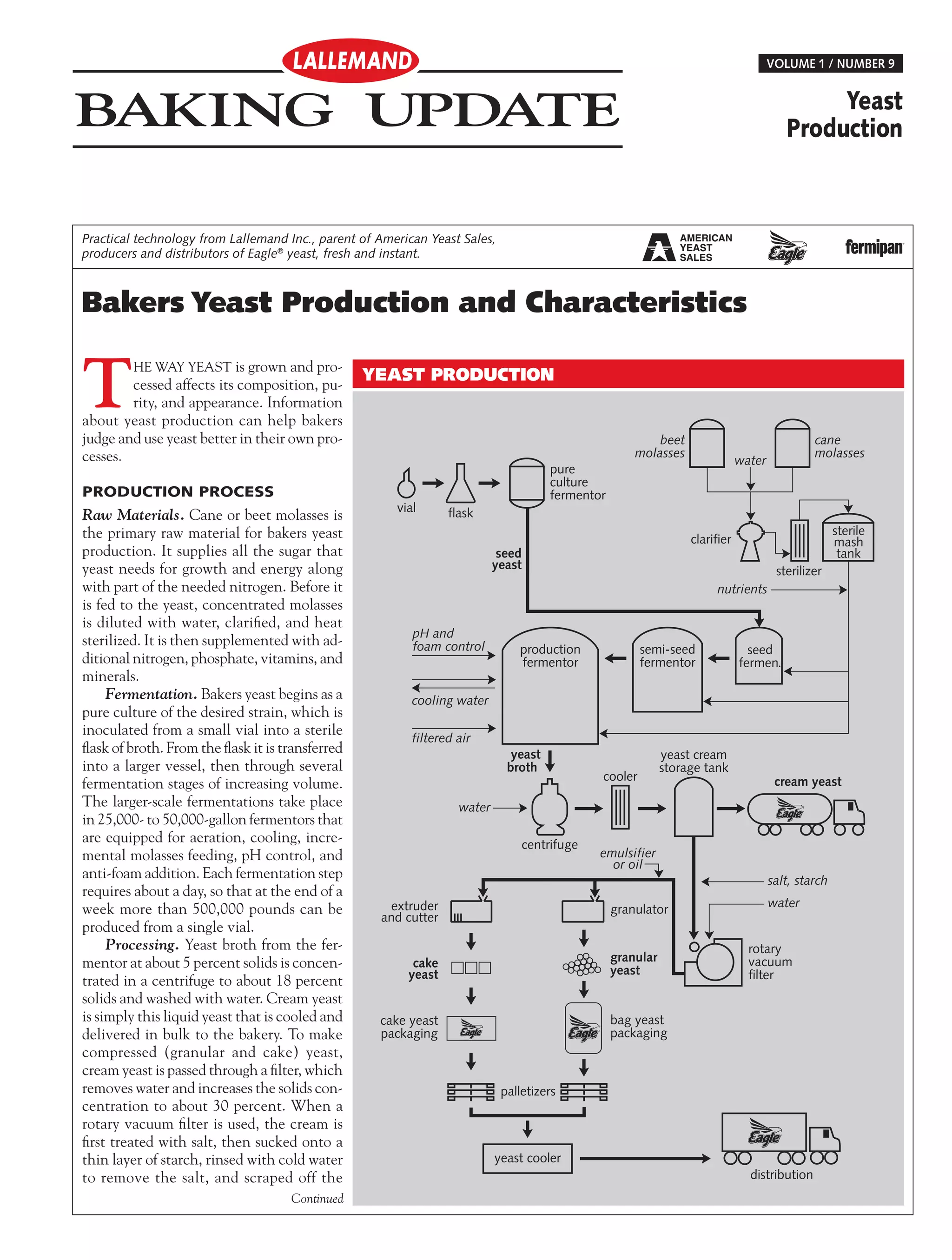

The document summarizes the process for producing bakers' yeast. It begins with raw materials like molasses which are sterilized and supplemented with nutrients. The yeast is then grown through several fermentation stages in large tanks. It is processed by centrifuging and filtering to produce cream yeast or compressed granular and cake yeast. The finished yeast contains proteins, carbohydrates and other components that can vary depending on production methods and conditions.