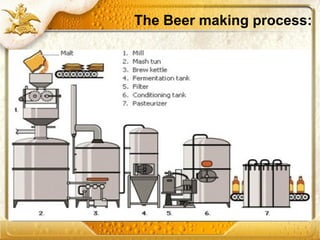

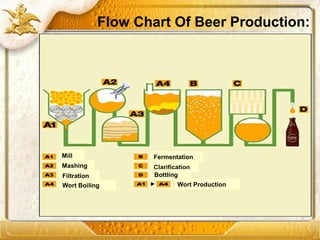

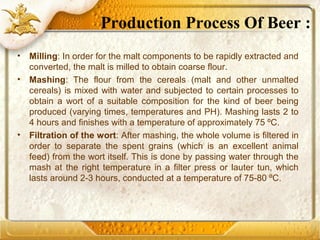

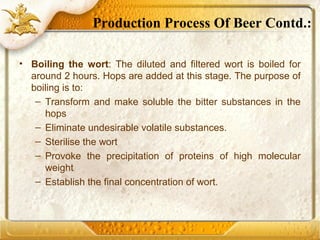

The document summarizes the process of beer production. It begins with a brief history of beer, noting it originated in Babylon in 6000 BC and was improved by Egyptians and commercially produced by Romans. It defines beer as a fermented alcoholic beverage made from grains like barley flavored with hops. The main ingredients in beer - barley, yeast, hops, water and other adjunct grains - are described along with their roles. The production process involves milling, mashing, boiling the wort, fermentation, clarification and bottling. Bottom and top fermenting beers are also defined based on the type of yeast used.