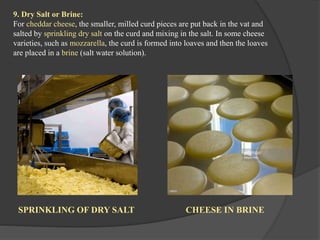

Cheese is made through a multi-step production process. Milk is standardized, pasteurized, cooled, and inoculated with starter bacteria. Rennet is added to coagulate the milk into a curd. The curd is cut, heated, drained, pressed, salted, and aged. The aging process can last from a few months to years depending on the cheese variety. The finished cheese is then packaged.