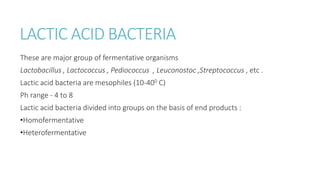

This document summarizes information about lactic acid bacteria and fermented foods. It discusses how lactic acid bacteria play an important role in food fermentation and preservation through producing lactic acid. Common fermented foods produced with lactic acid bacteria include sauerkraut, pickles, yogurt, cheese, buttermilk, kimchi, idli and dosa. The document provides details on the microorganisms involved and production processes for several of these fermented foods.