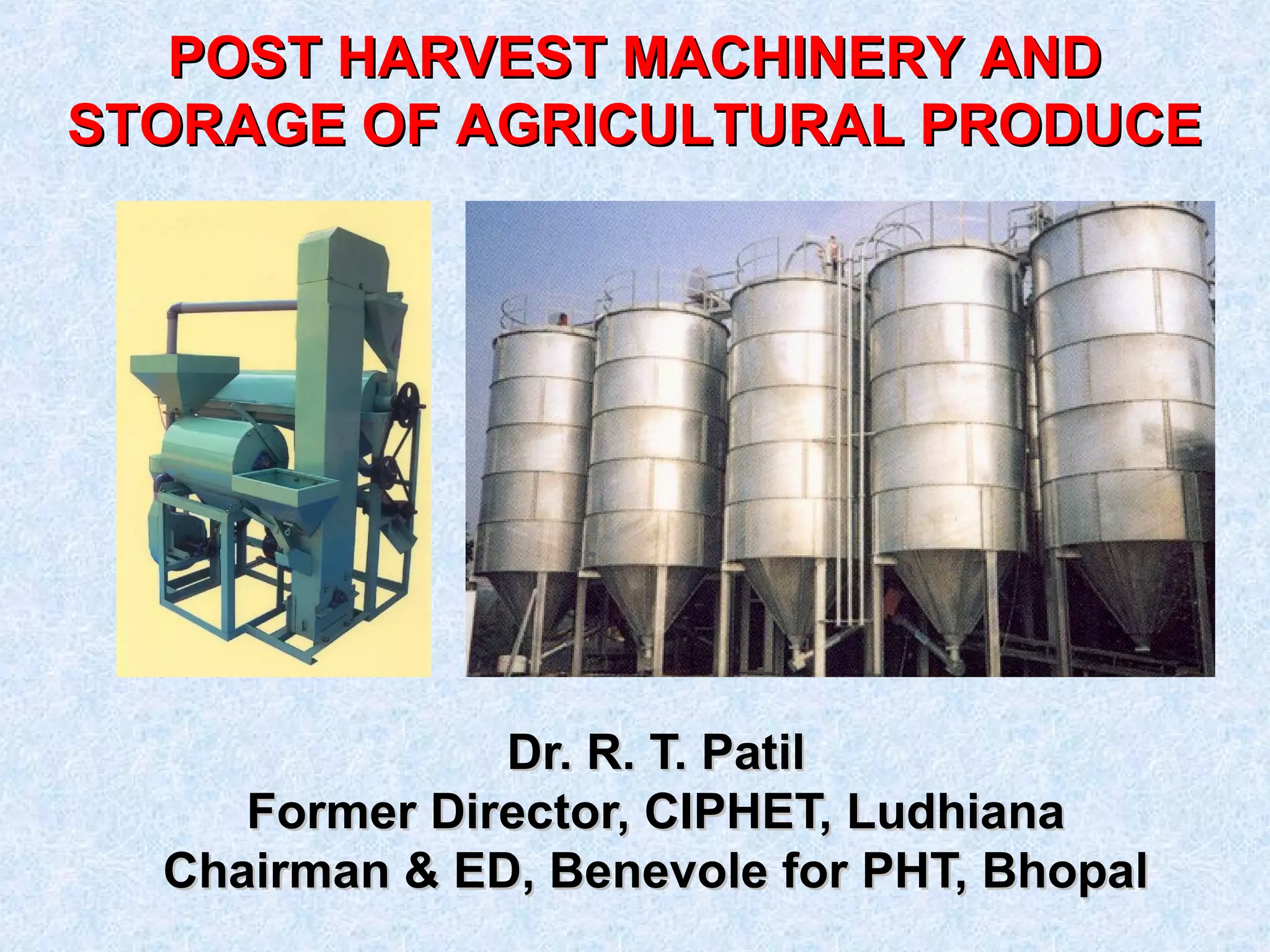

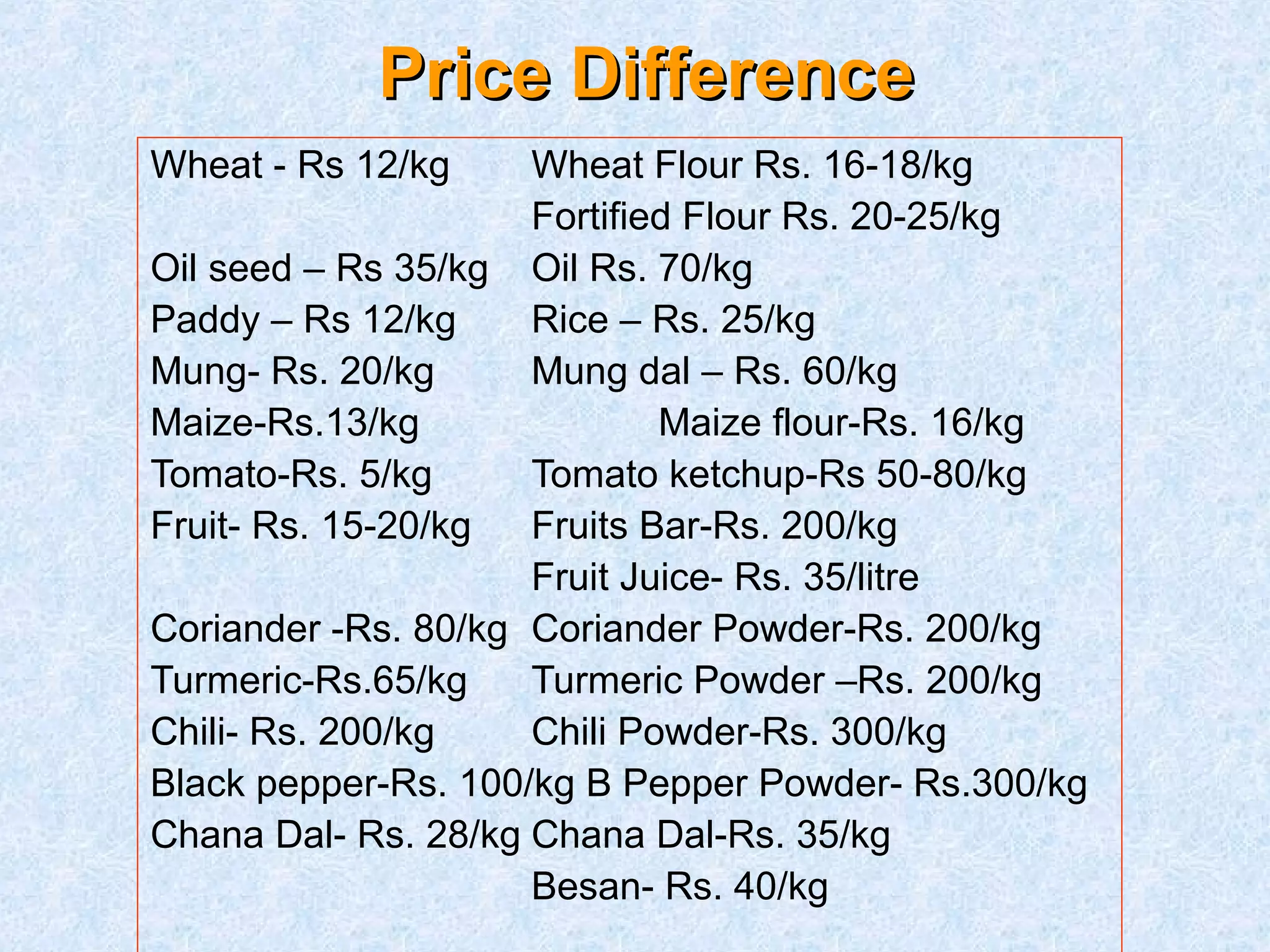

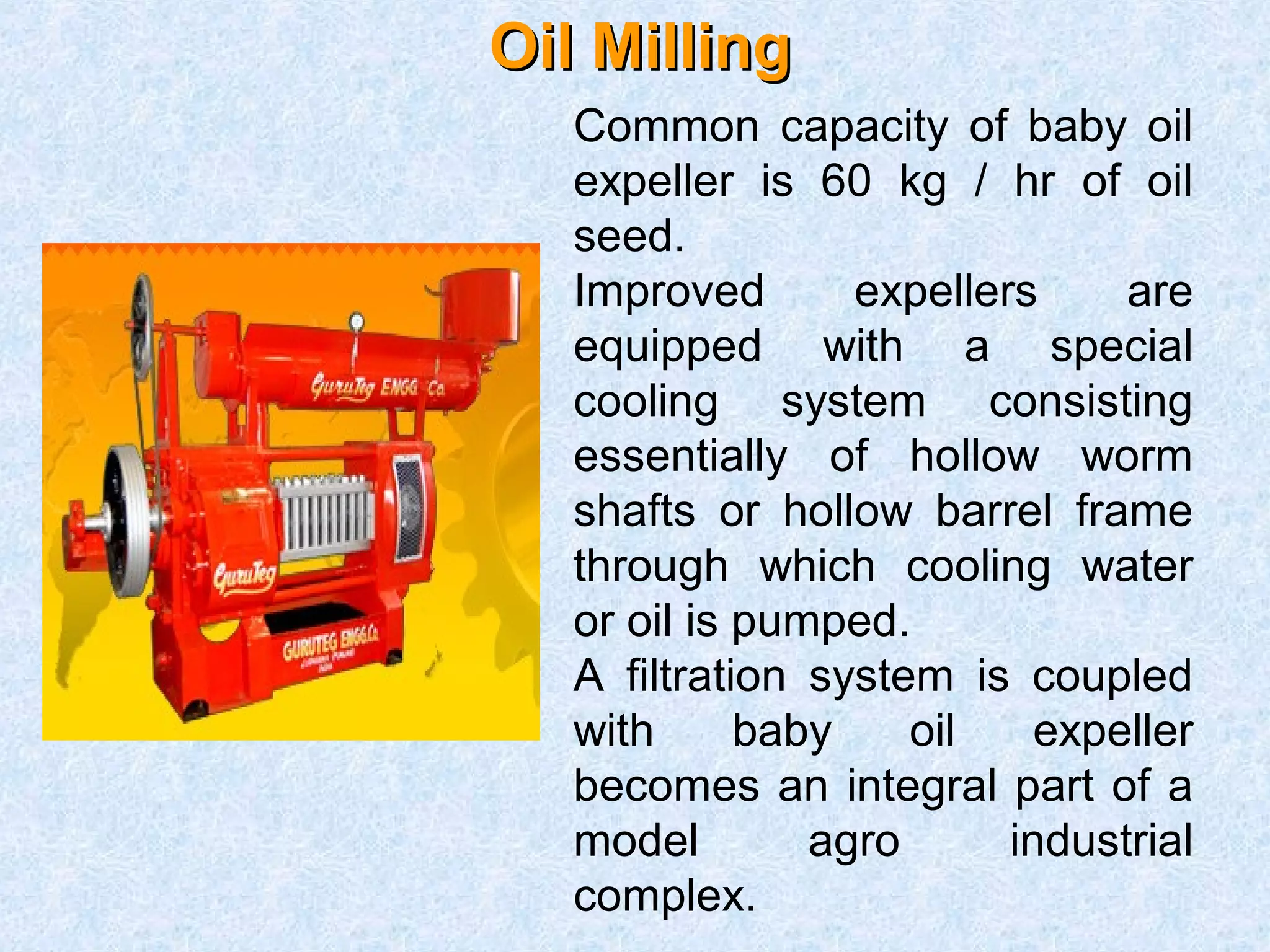

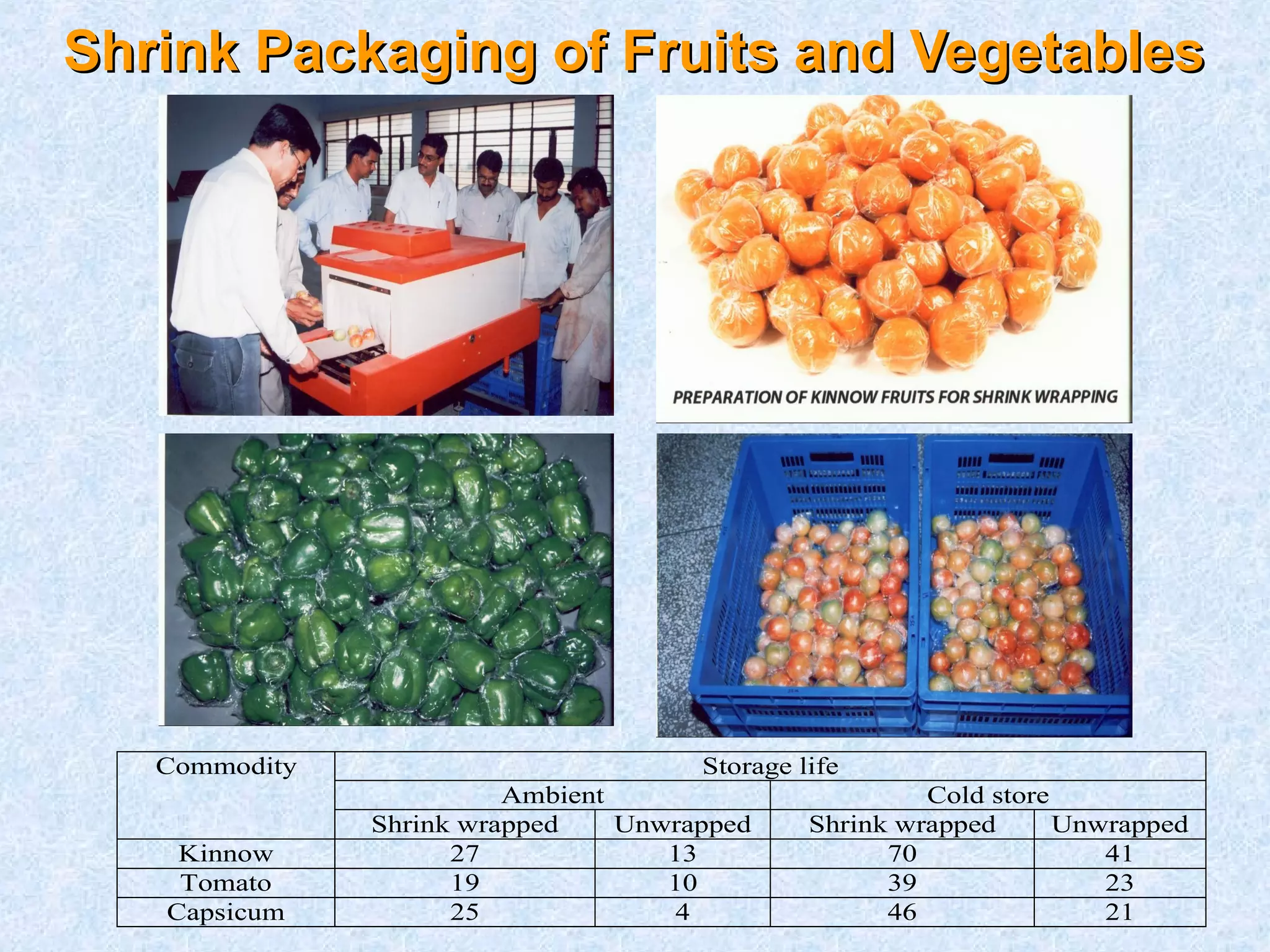

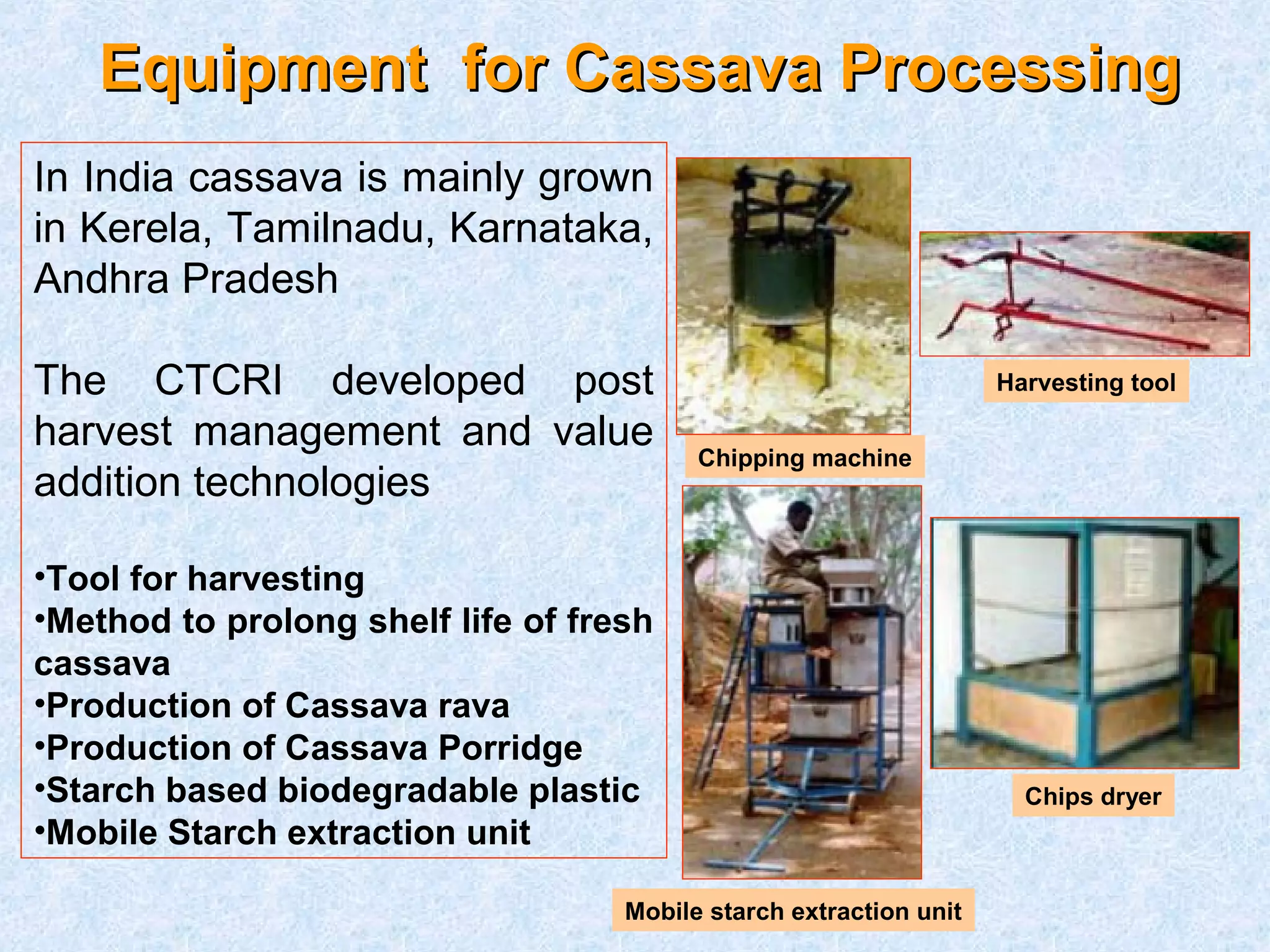

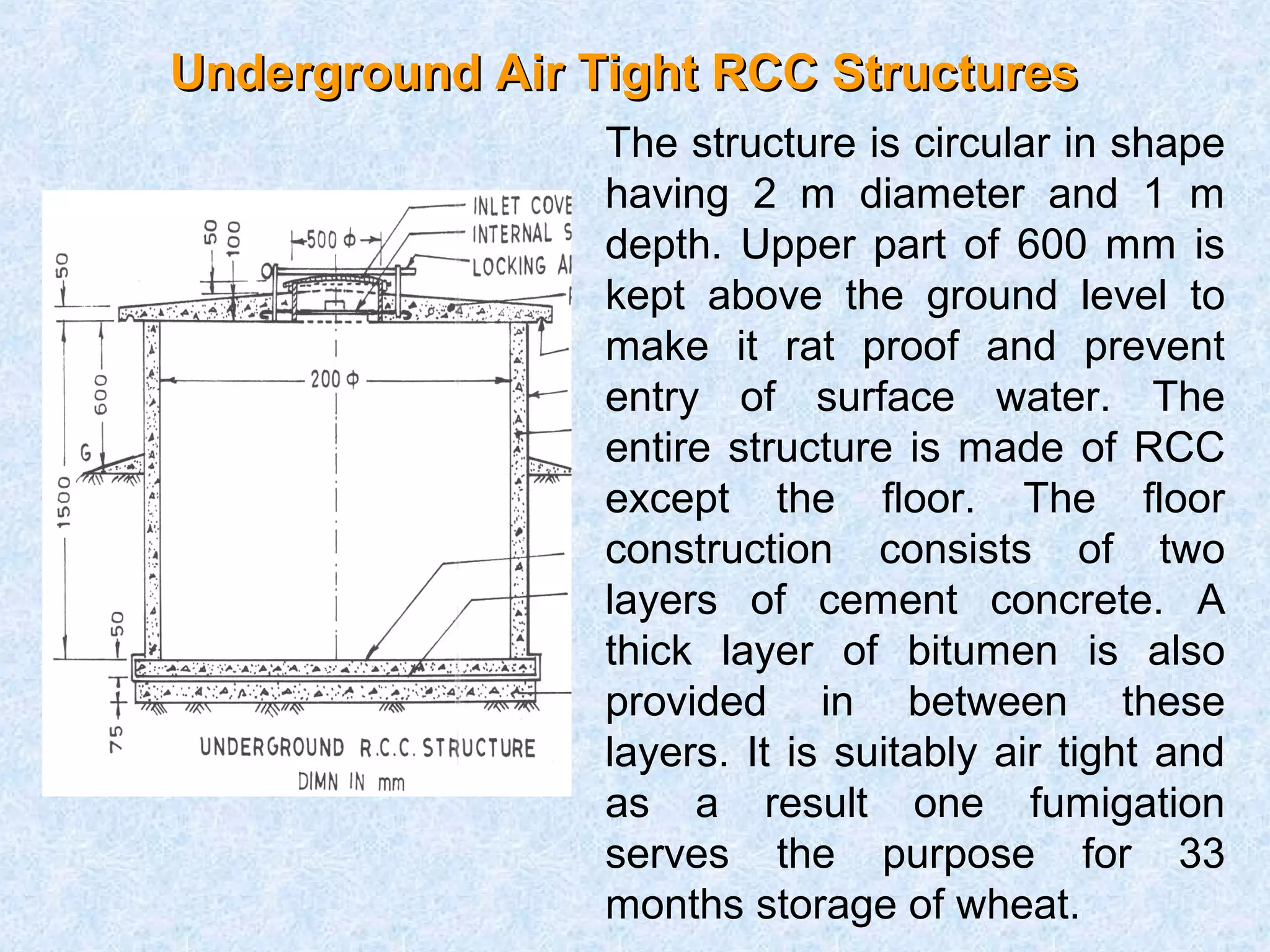

The document discusses the significance of post-harvest management and processing technologies in Indian agriculture, highlighting that the sector contributes significantly to GDP and employs a large workforce. It emphasizes the necessity for modern machinery in food processing to minimize losses and improve the profitability of farmers, providing various examples of machinery and their capacities. Recommendations for enhancing processing standards and storage solutions are also presented to align with modern agricultural needs.