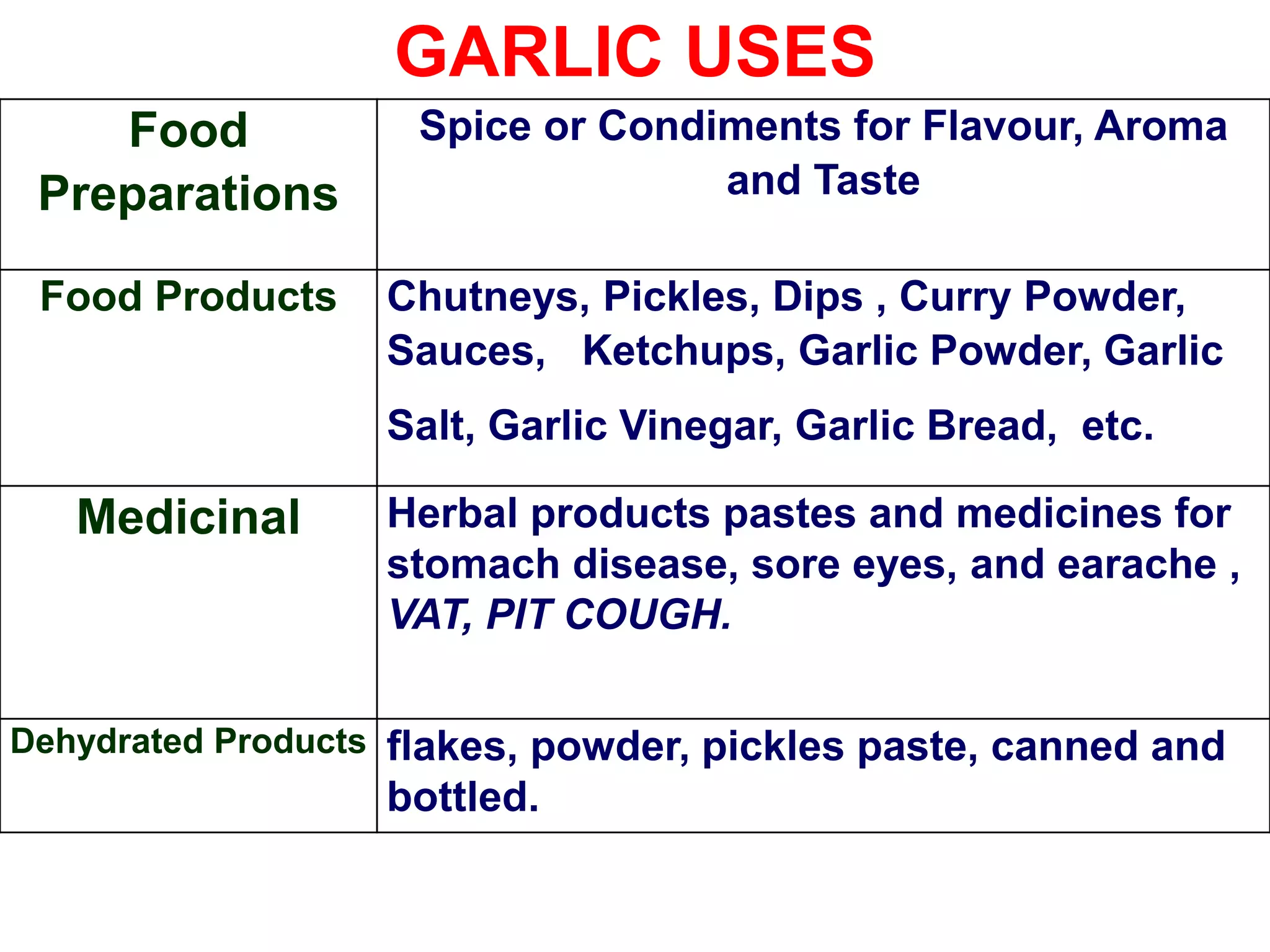

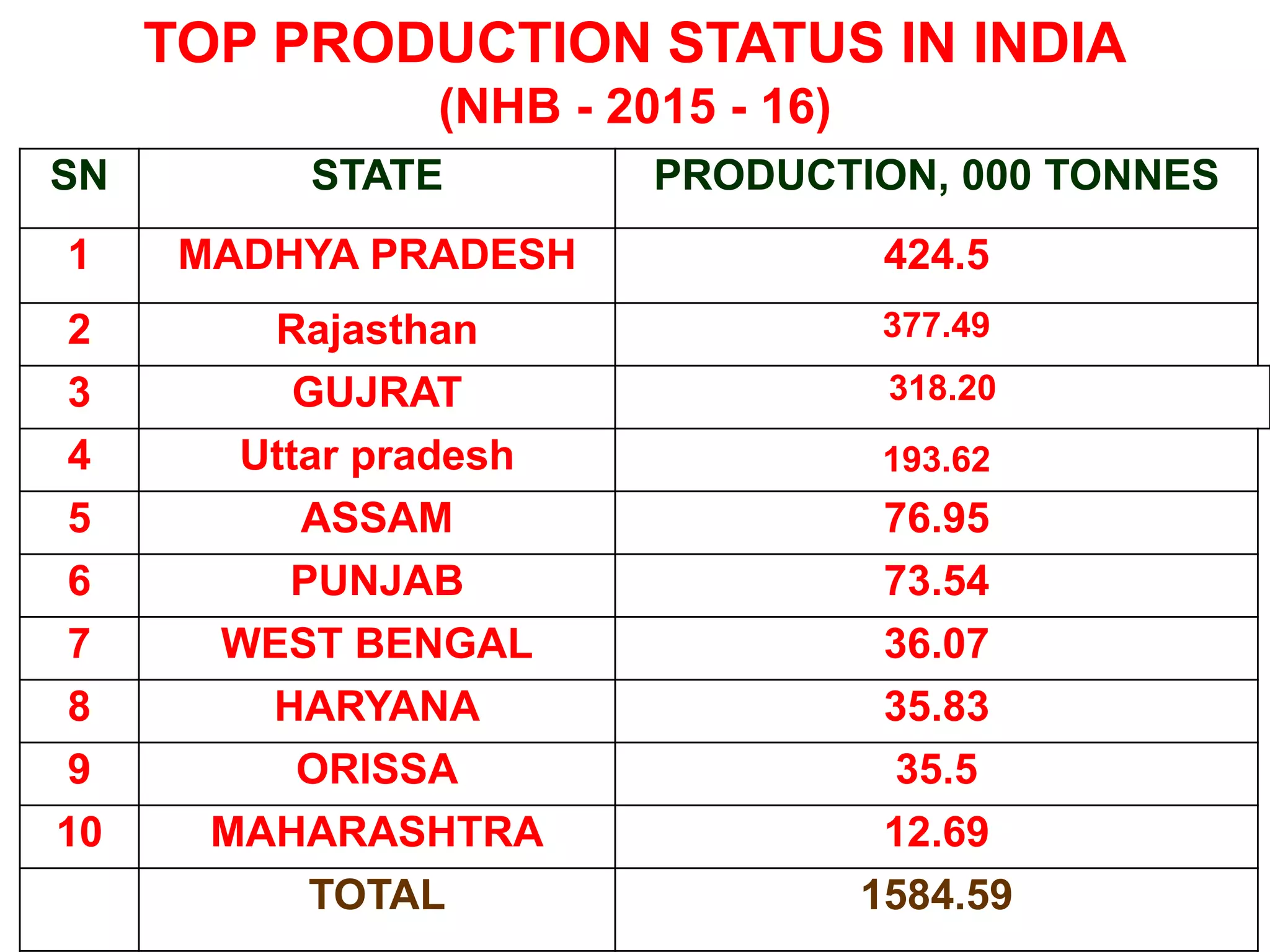

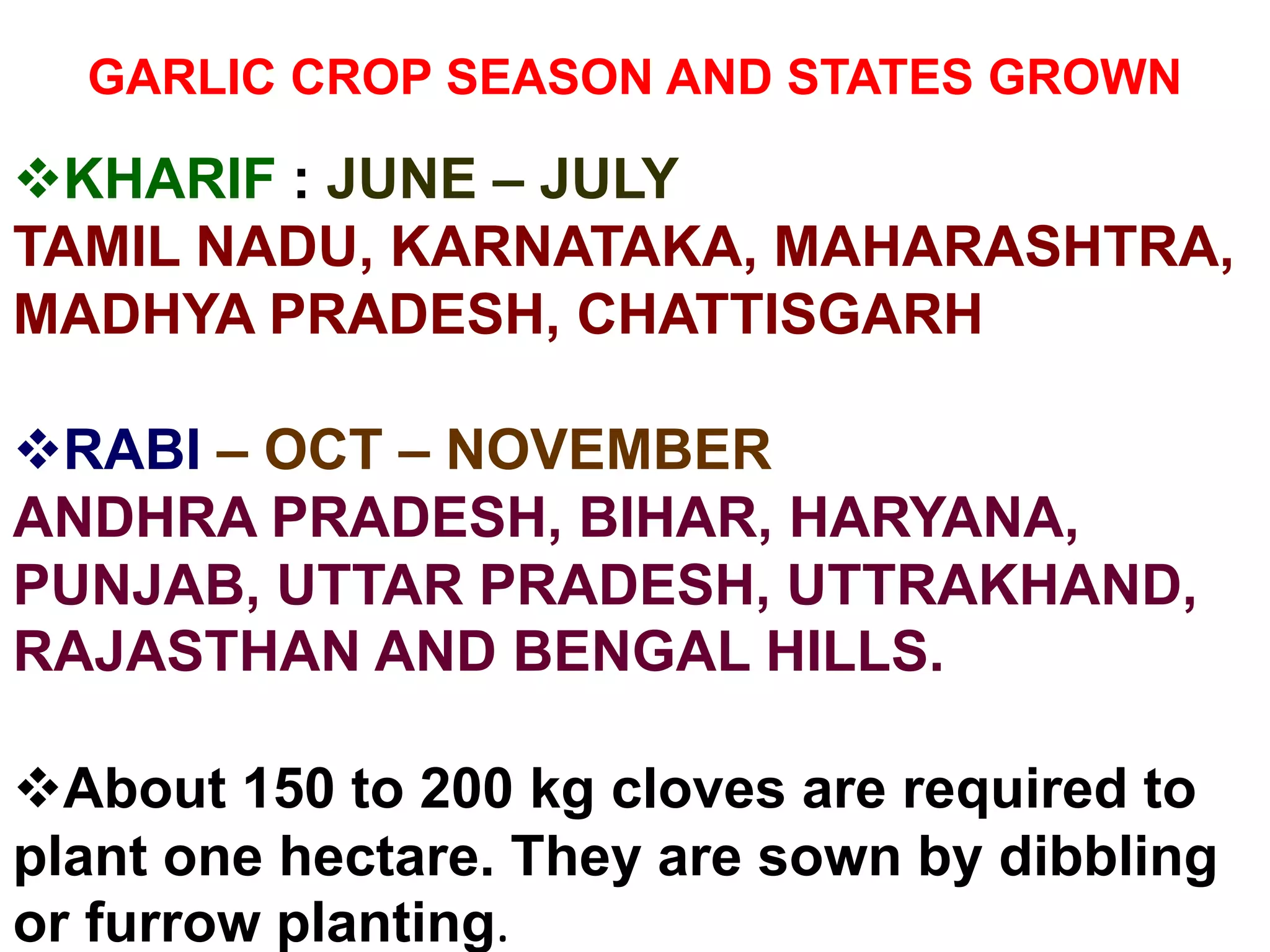

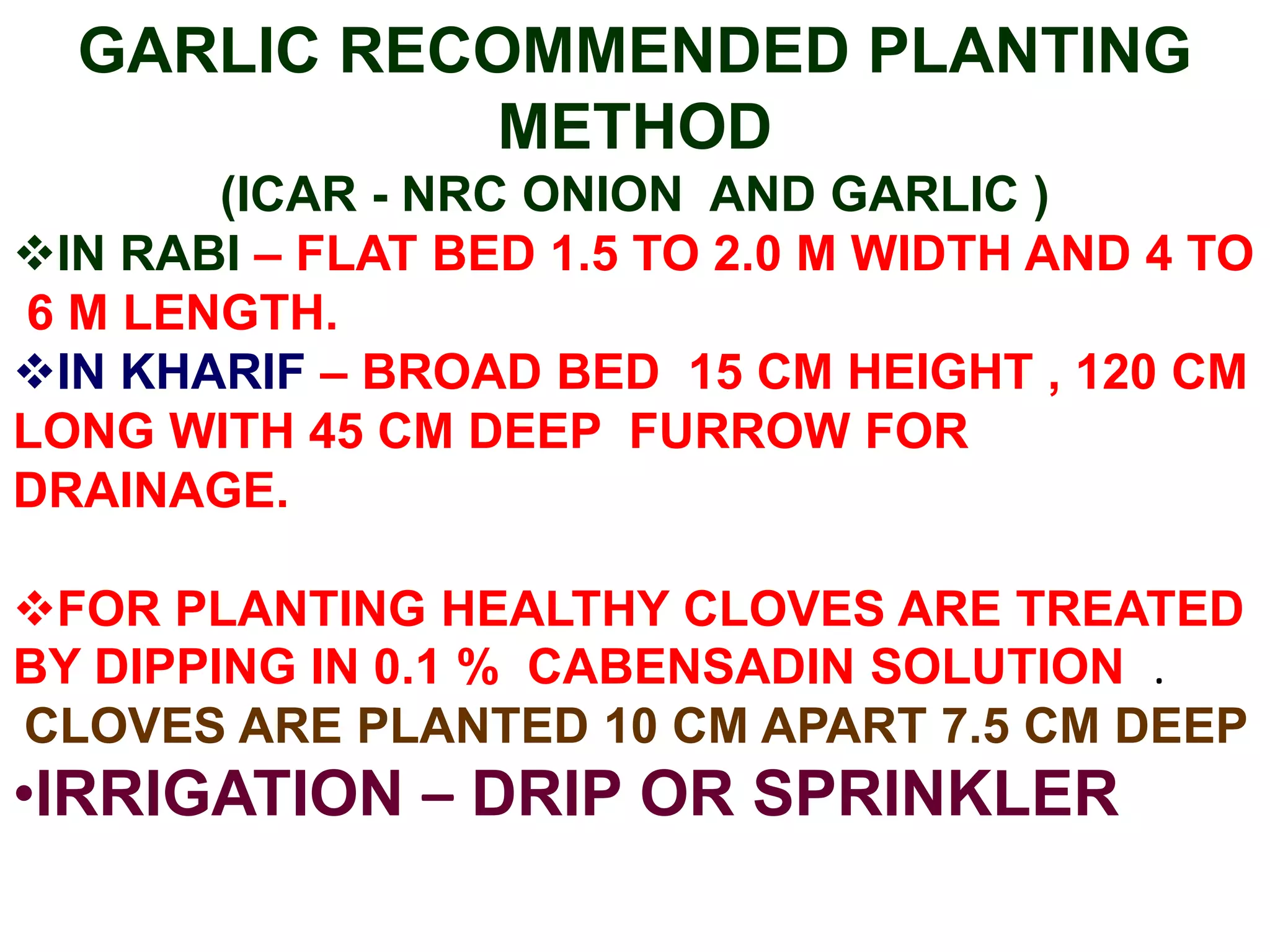

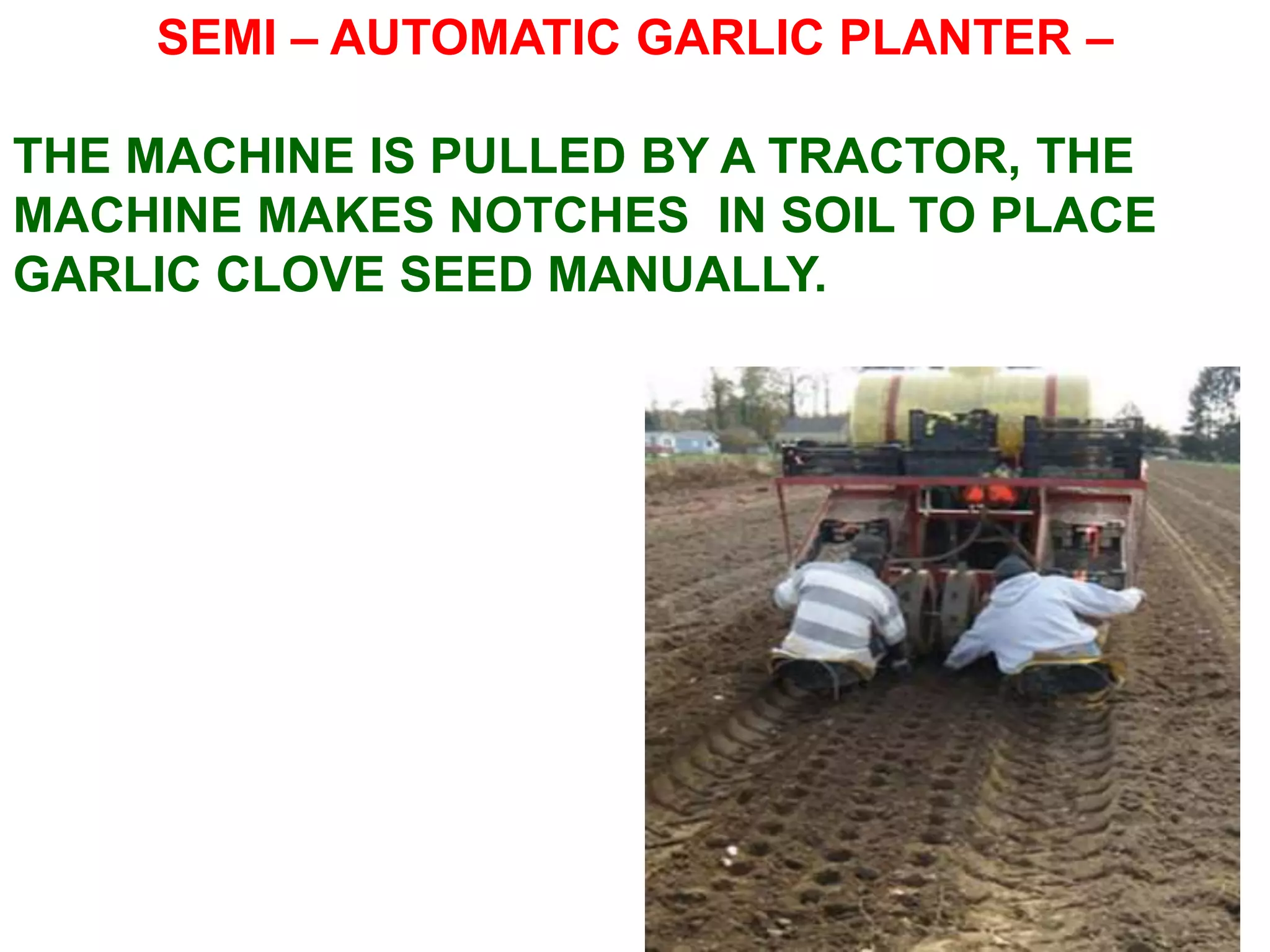

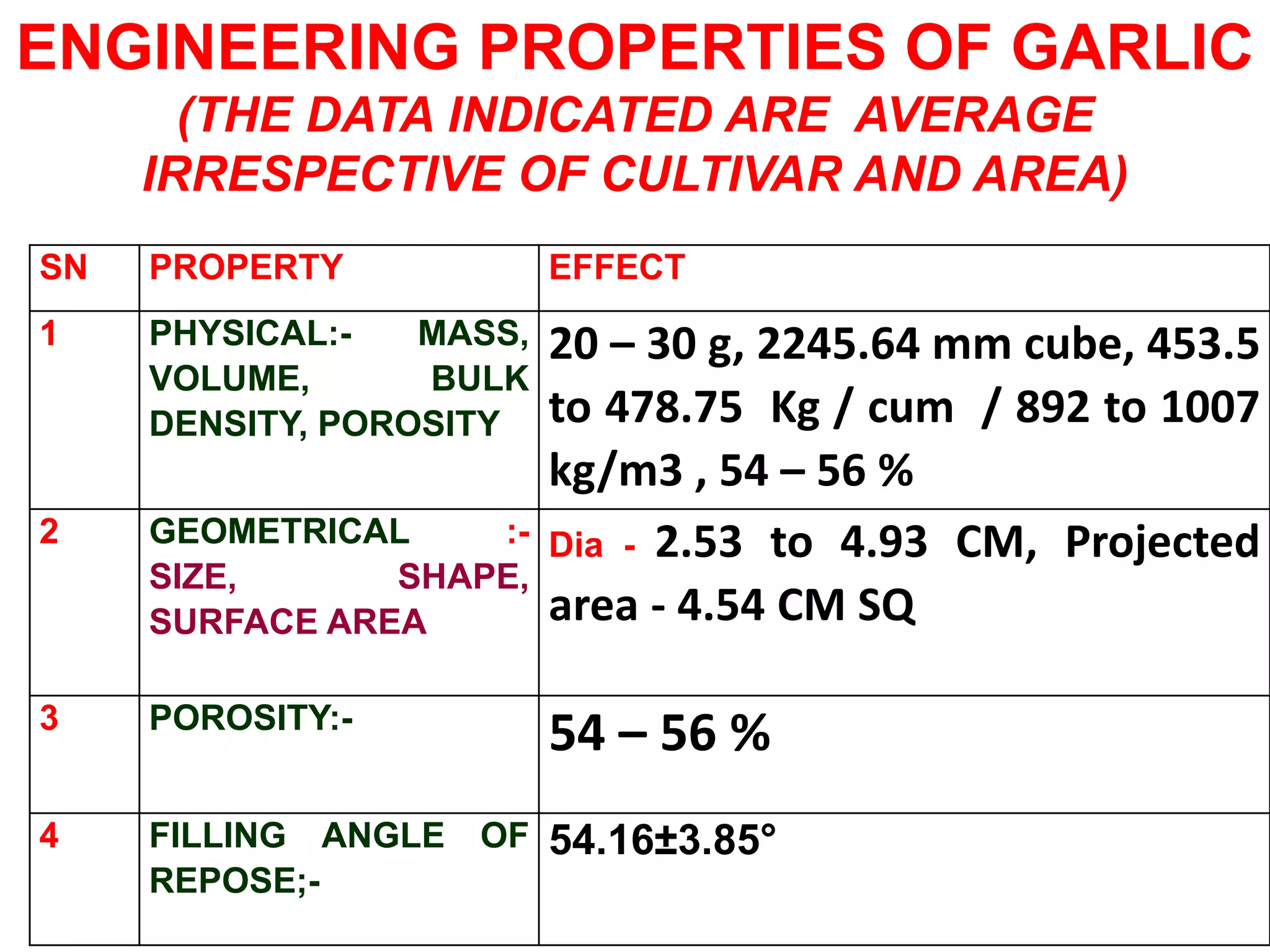

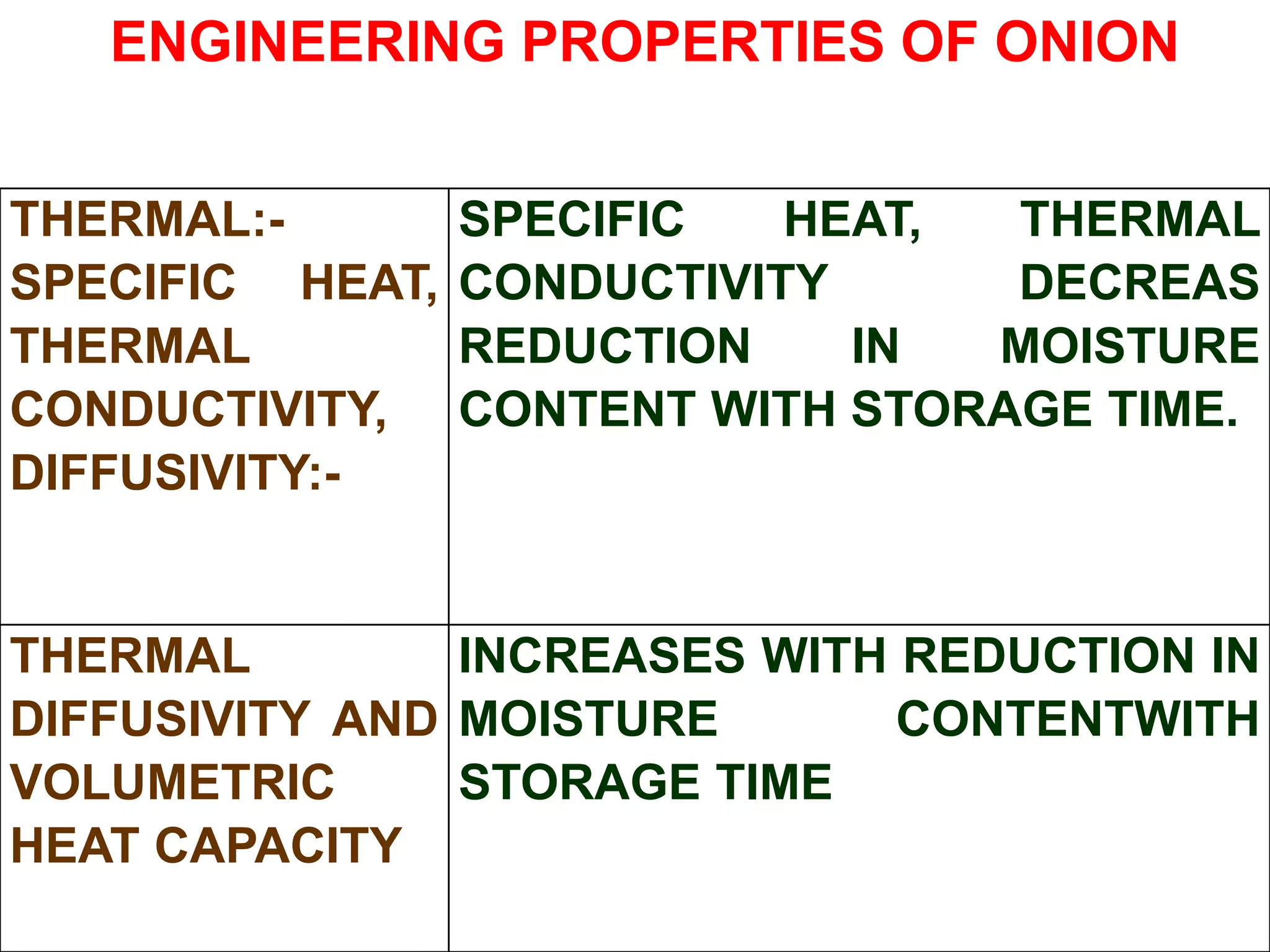

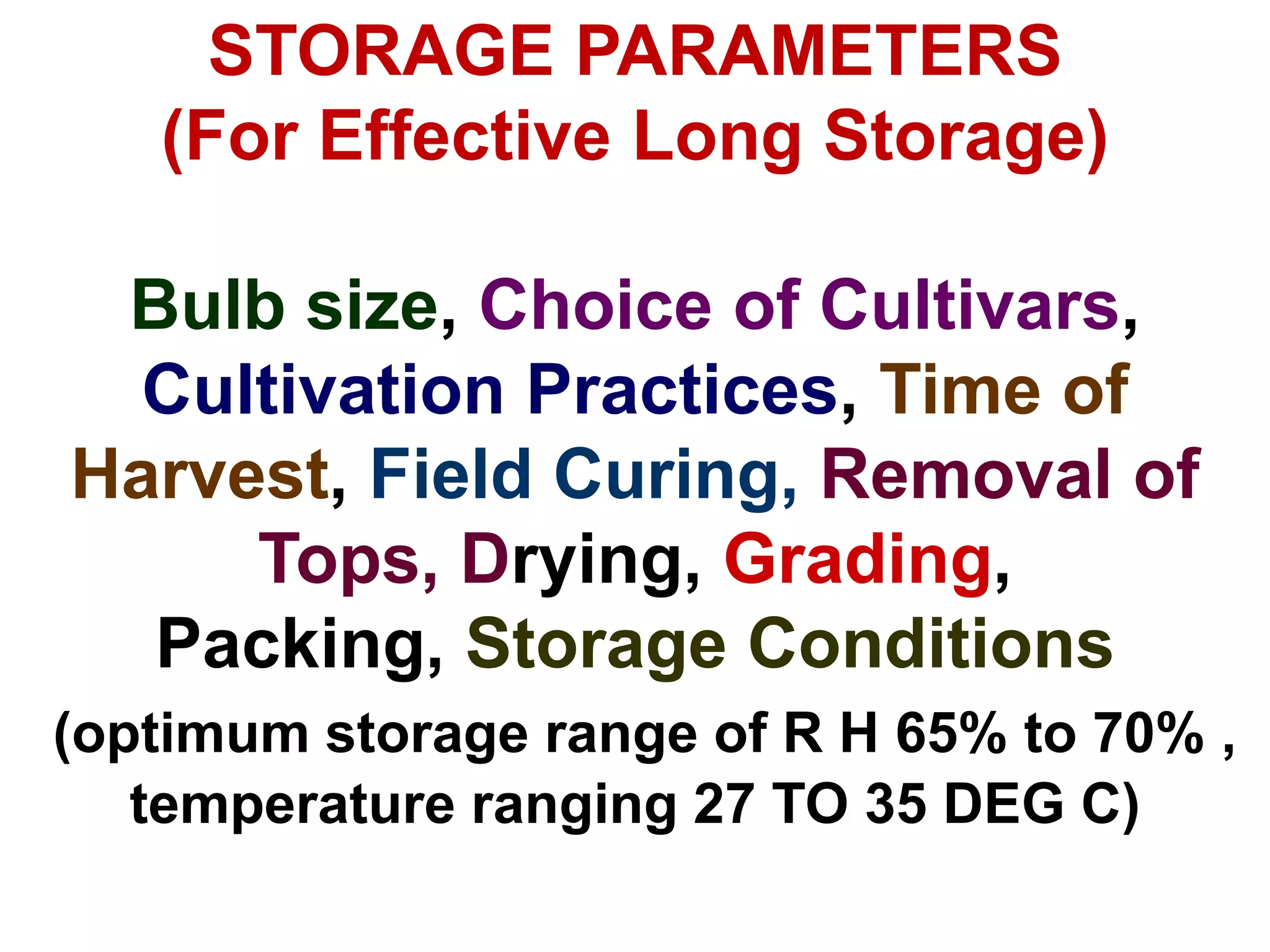

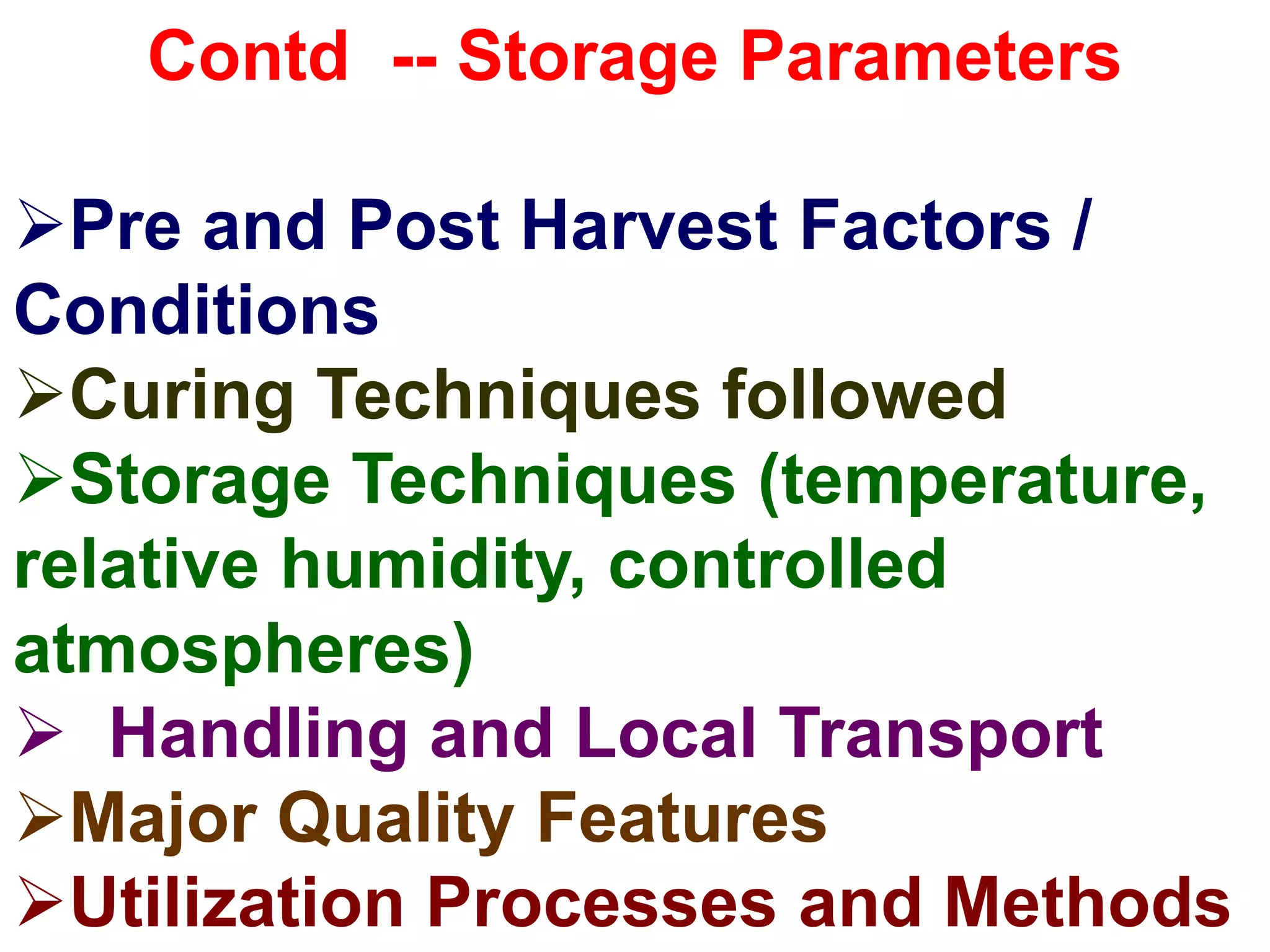

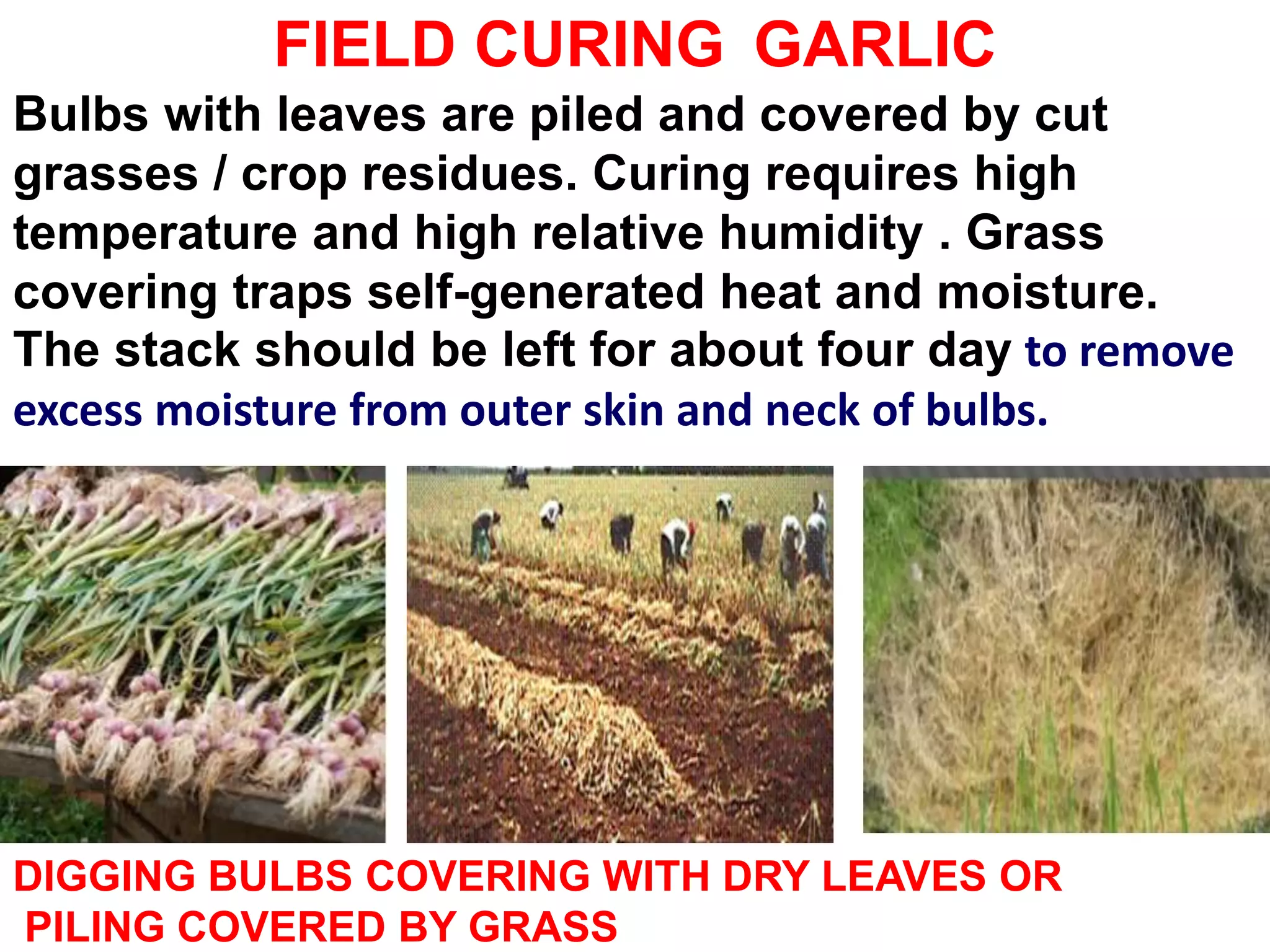

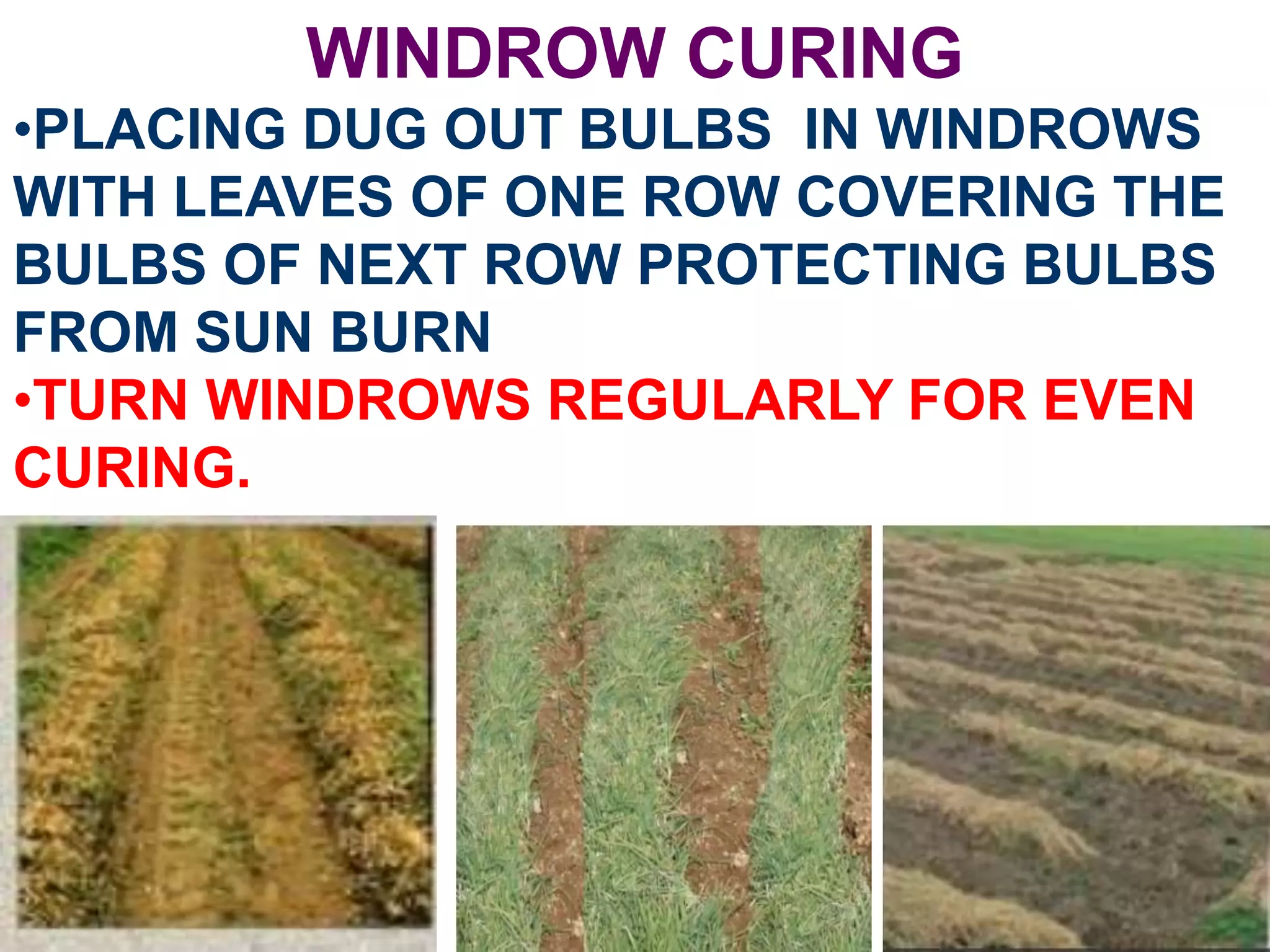

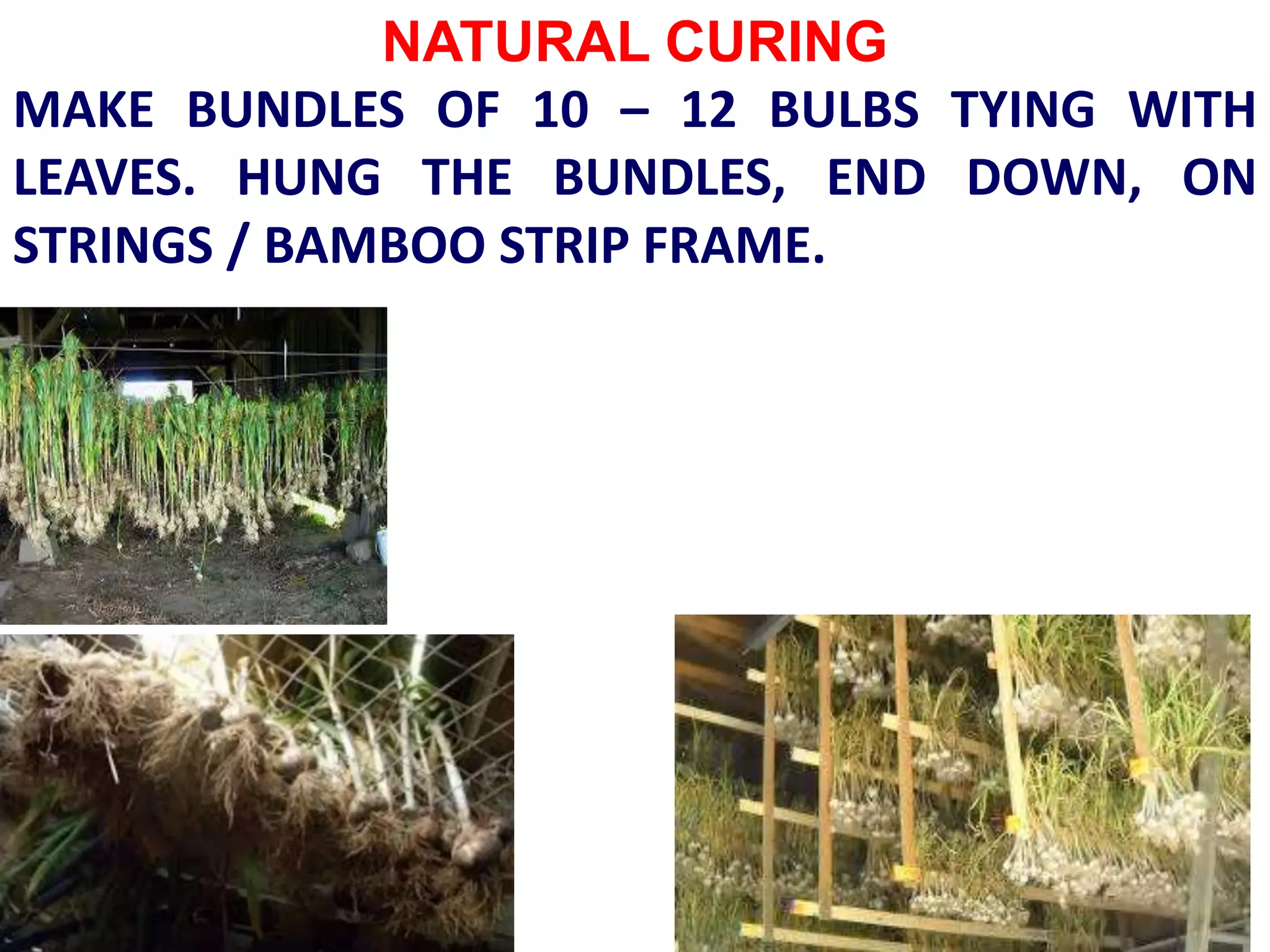

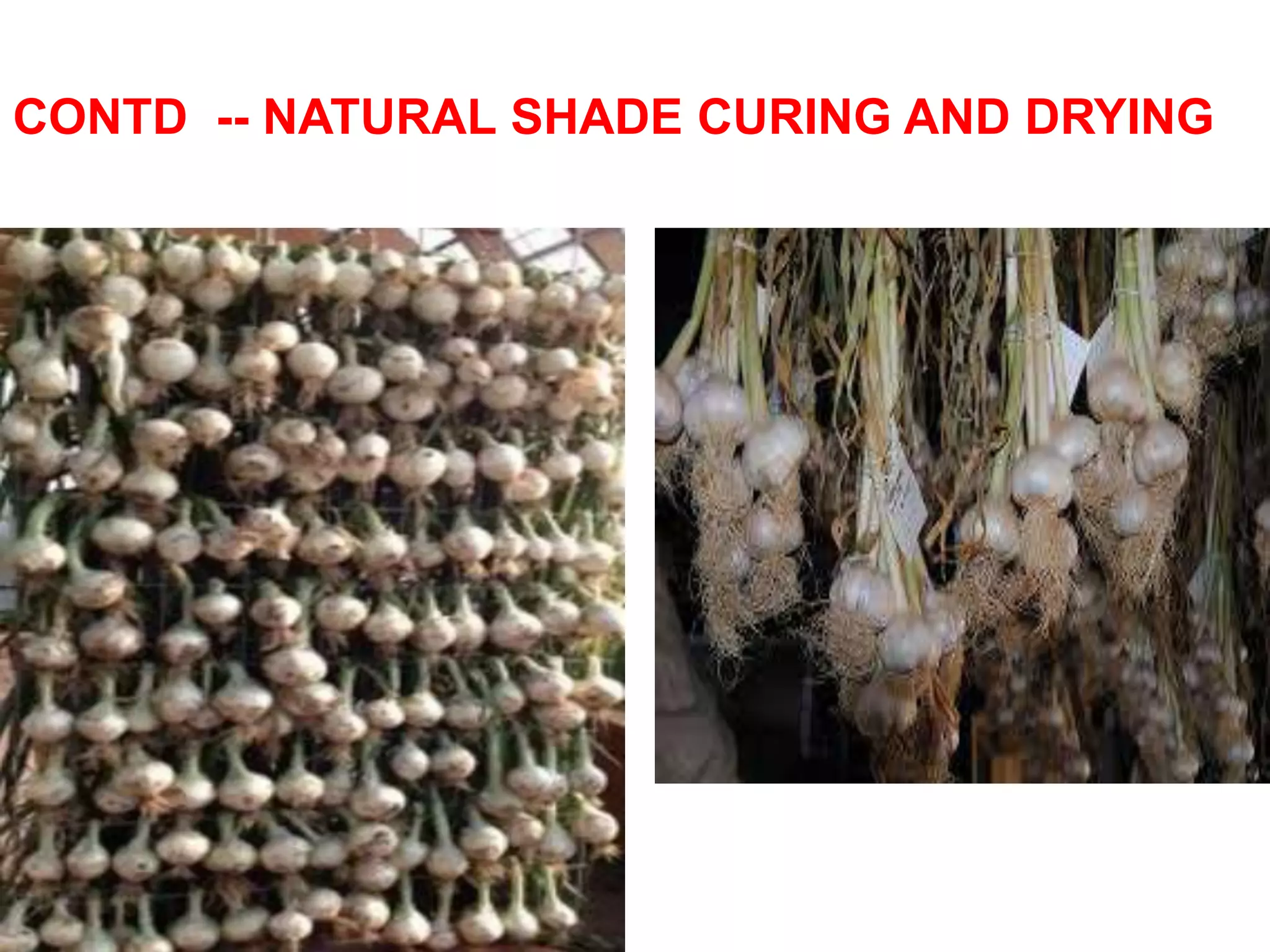

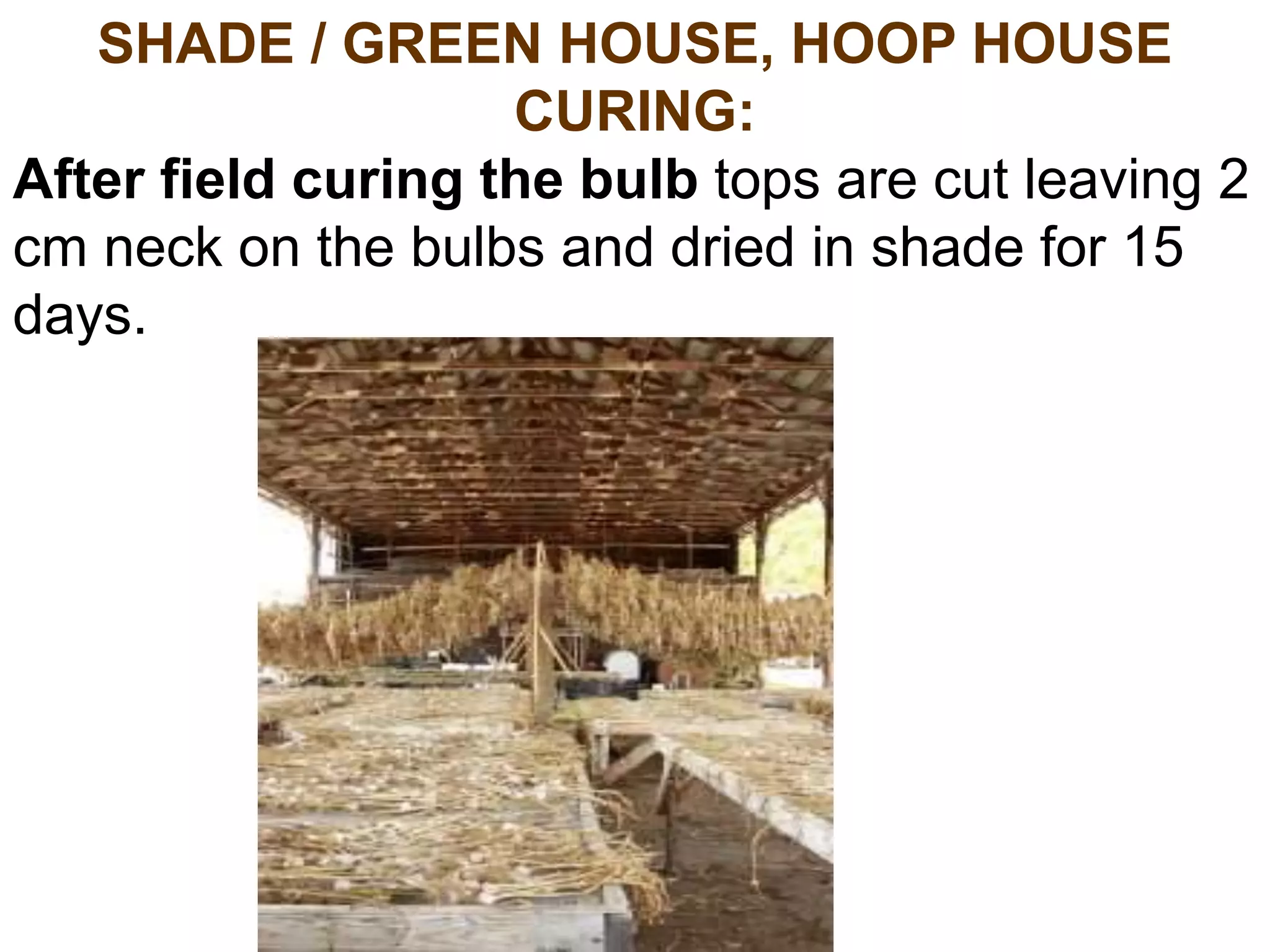

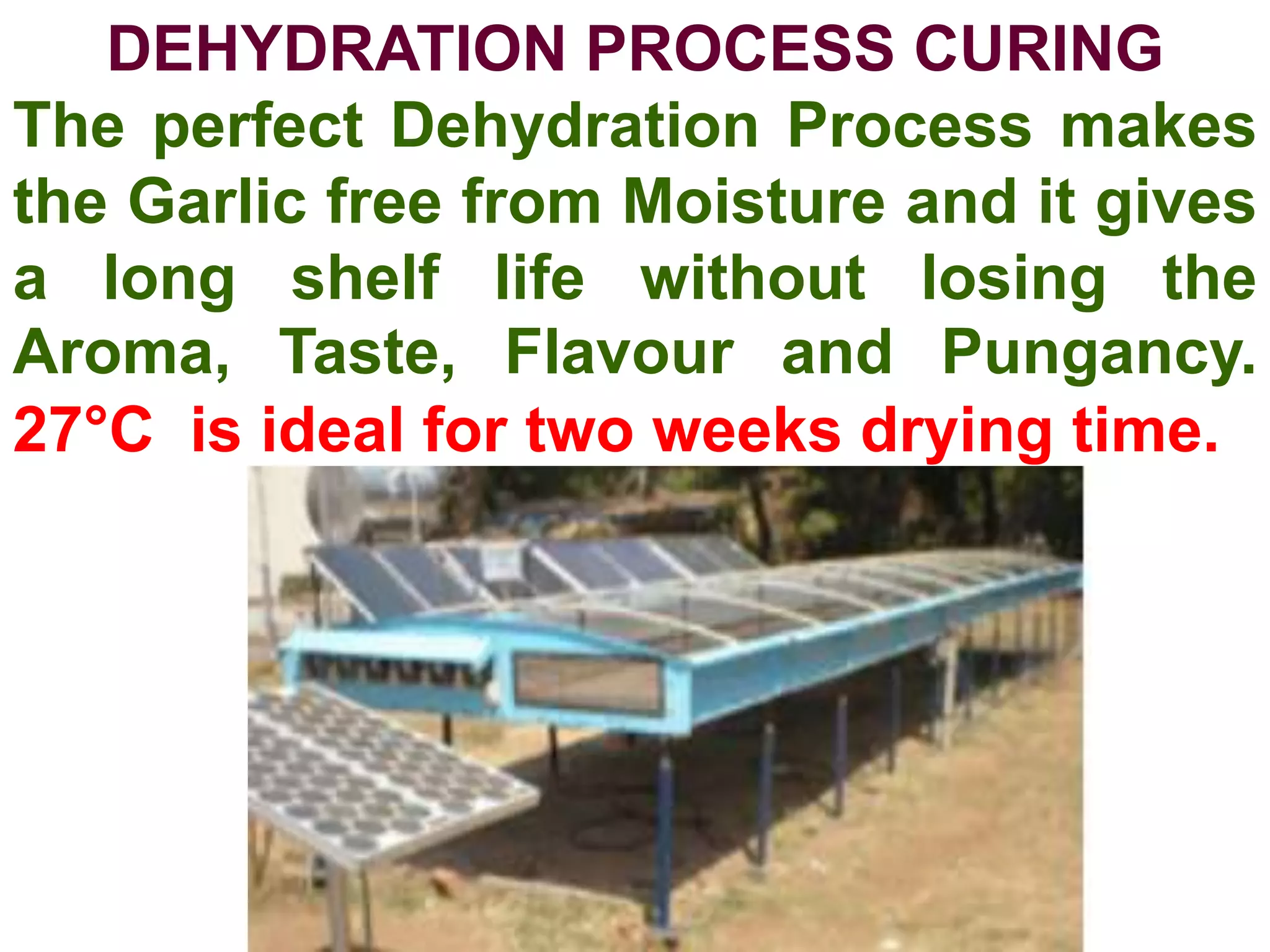

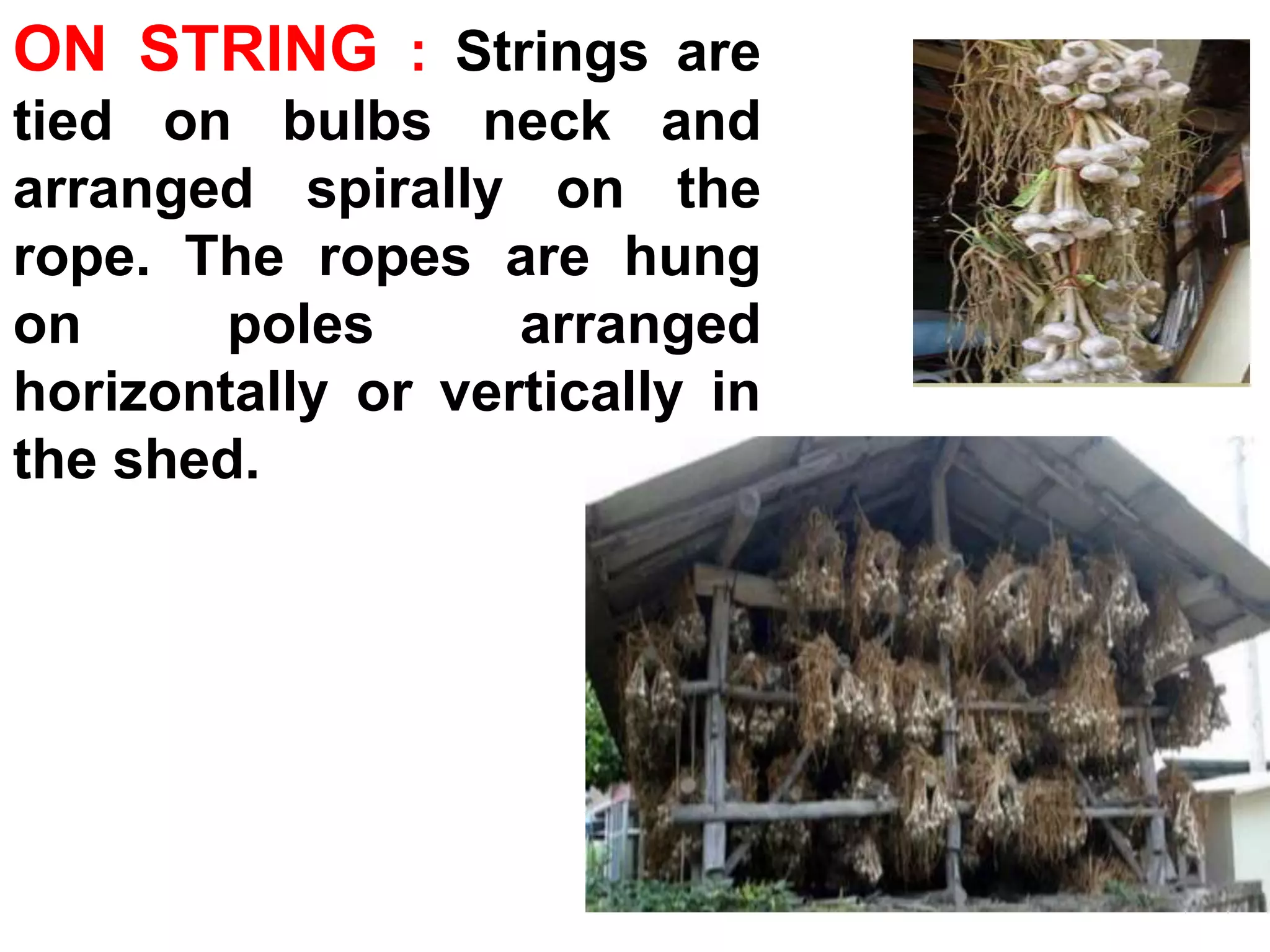

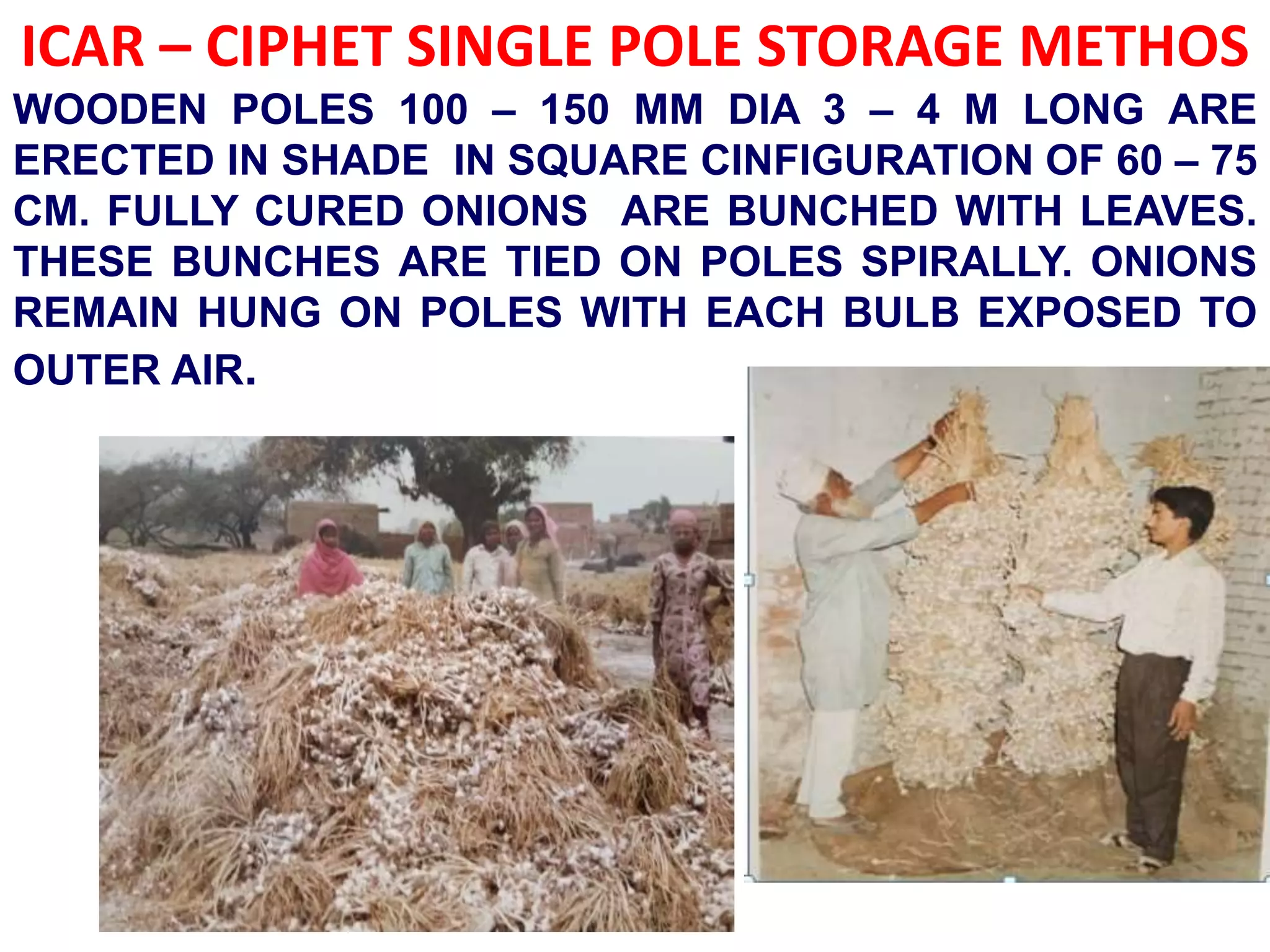

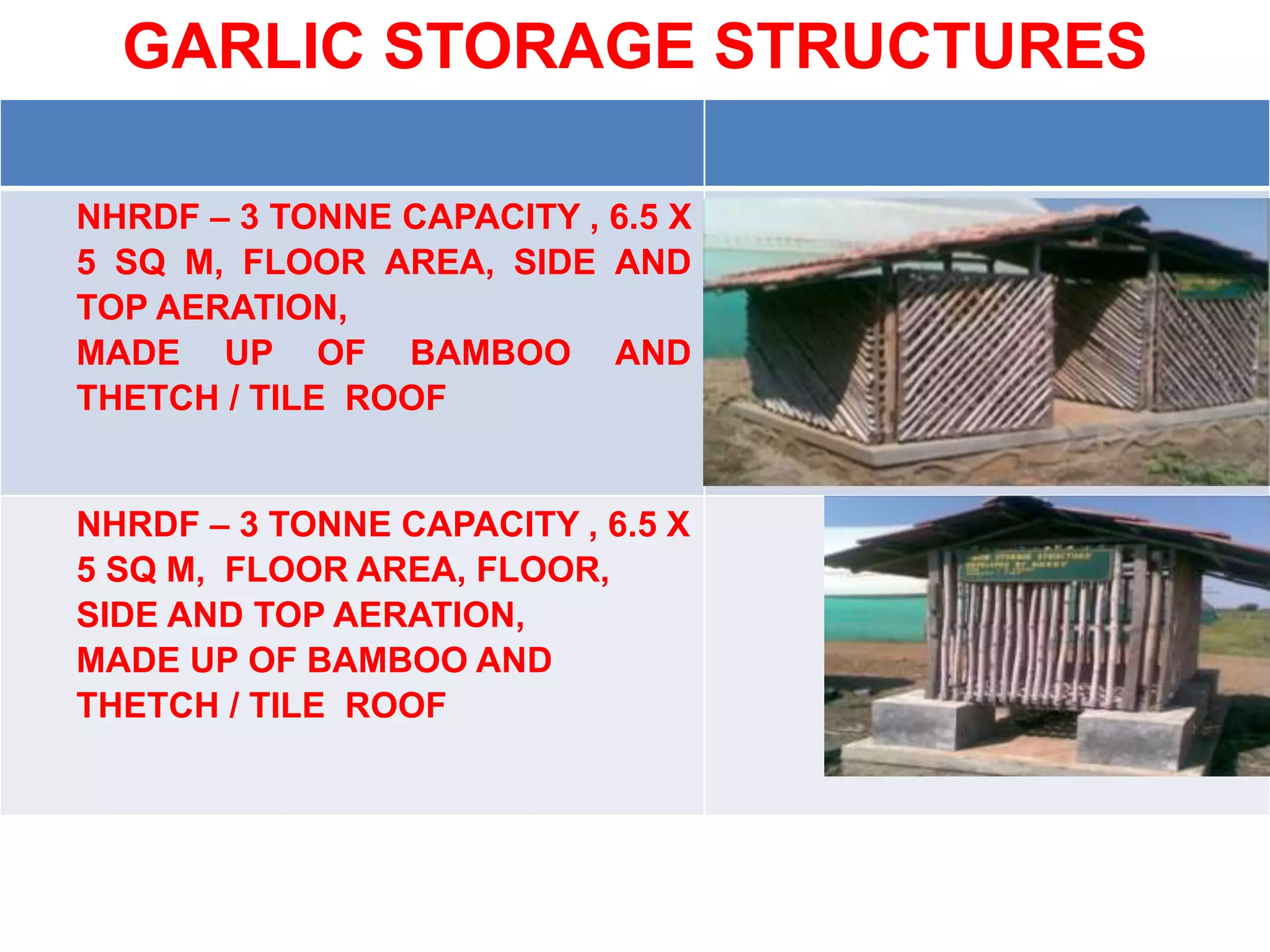

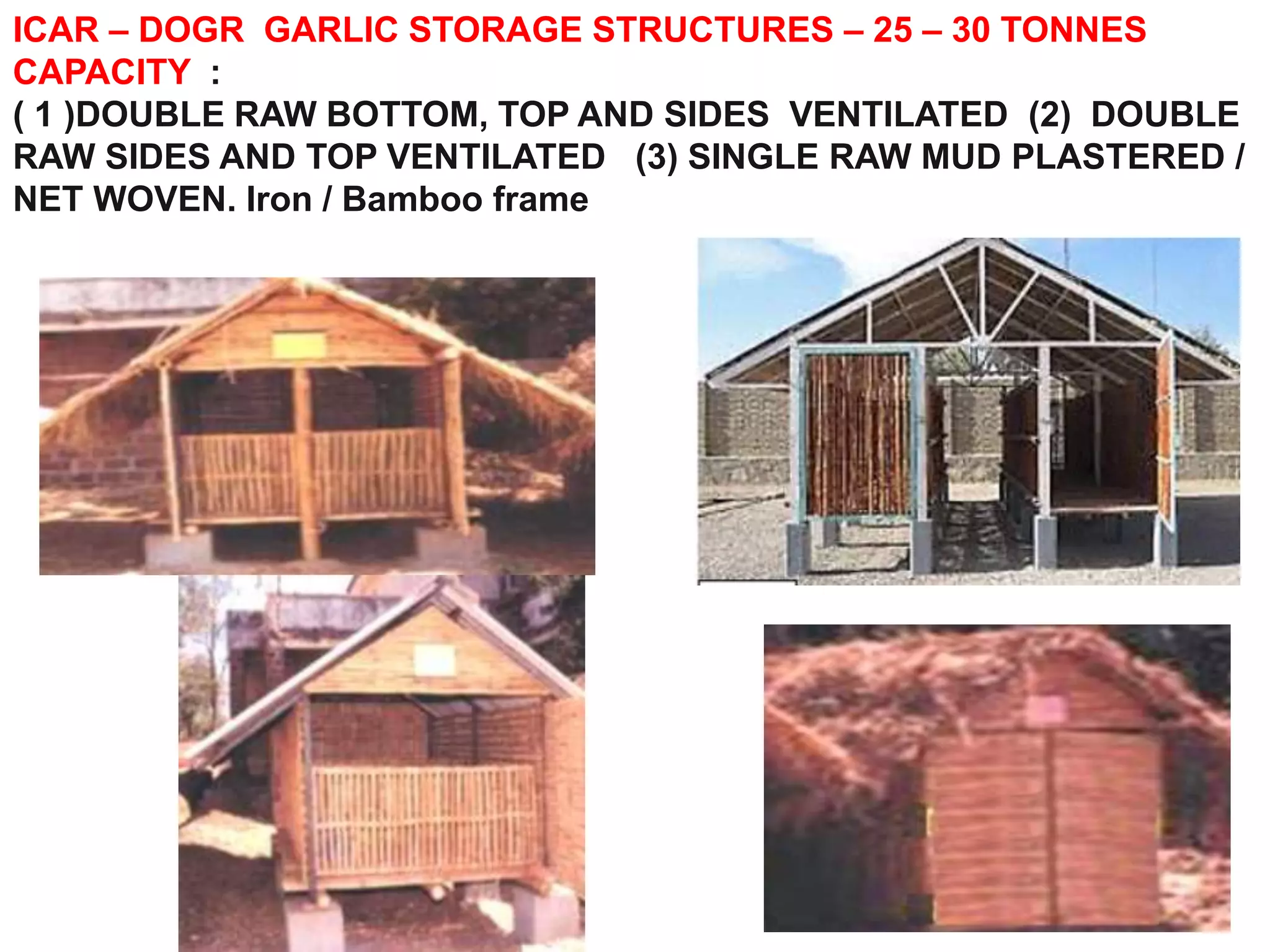

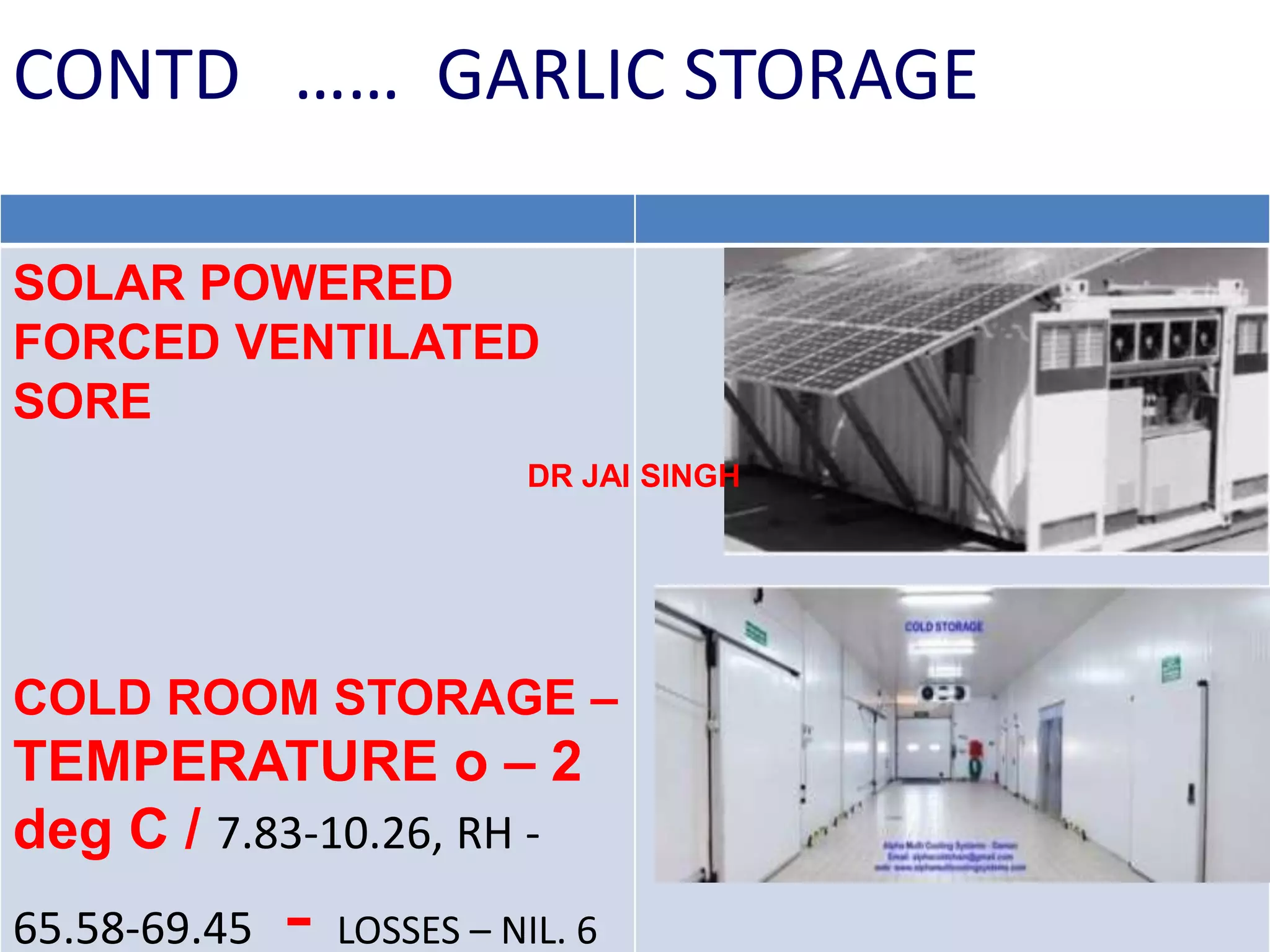

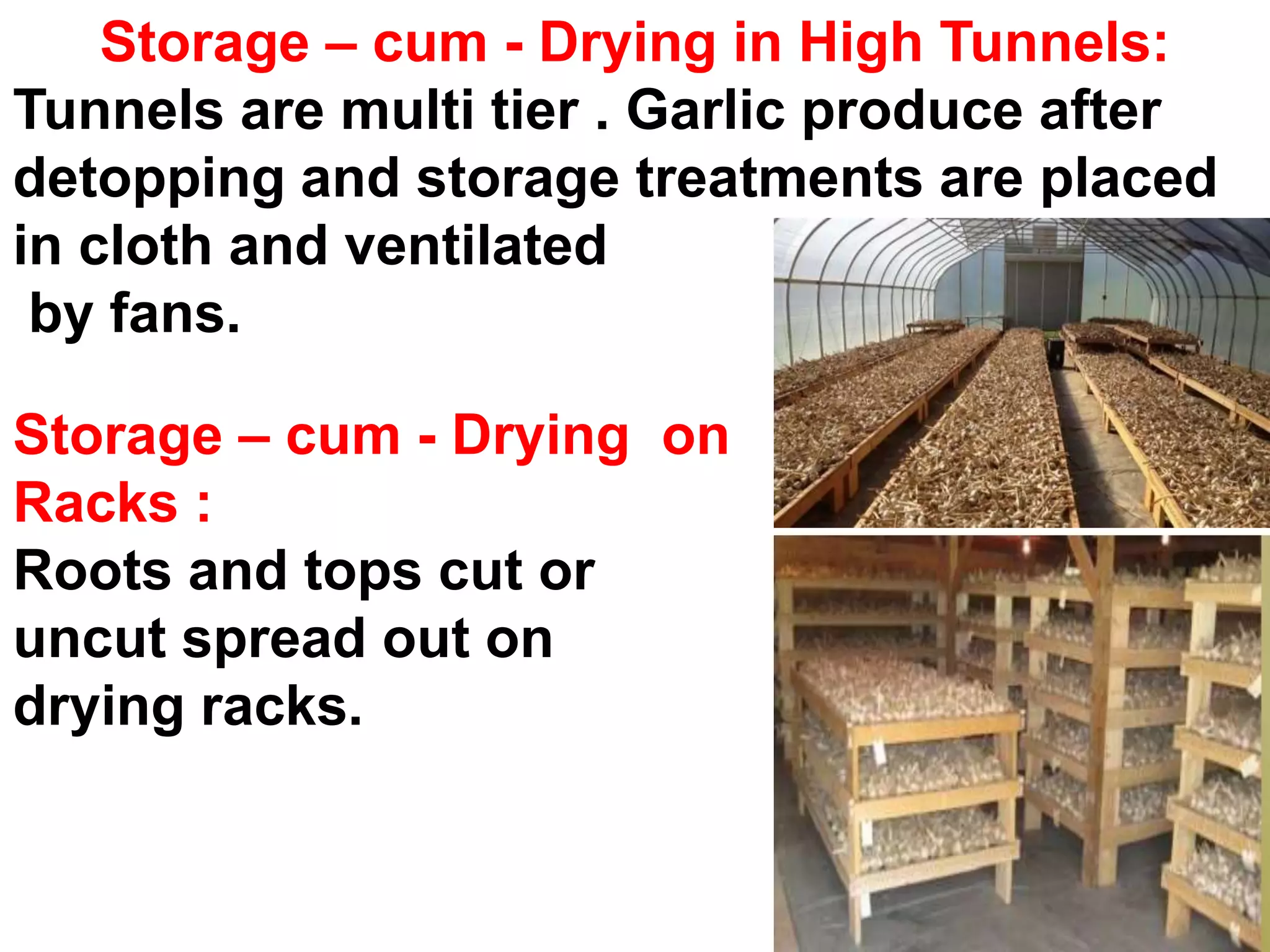

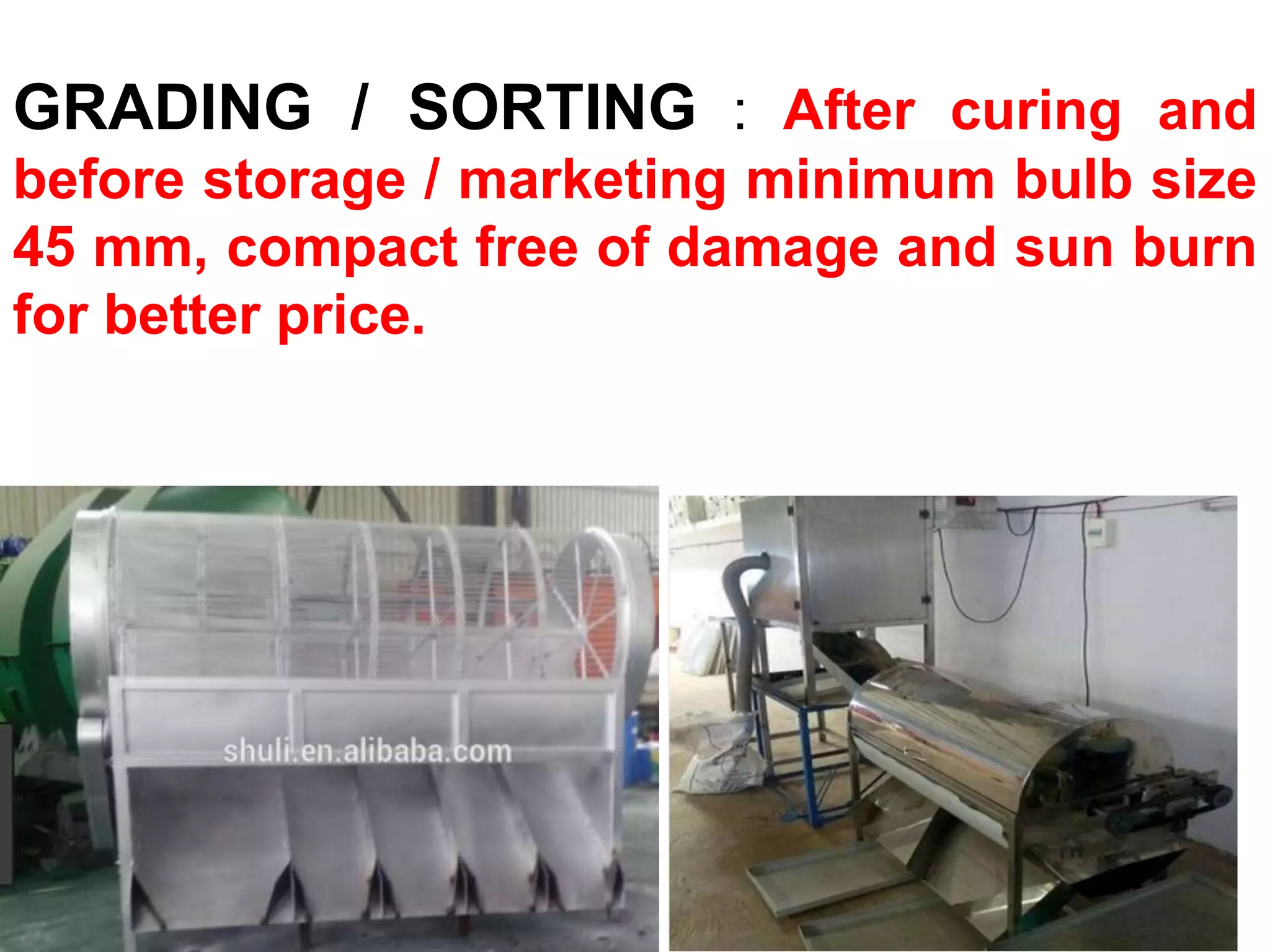

This document provides information on growing, harvesting, curing, and storing garlic. It discusses popular garlic varieties in India, their uses, top producing states, and growing seasons. Methods of planting, harvesting, curing, and storing garlic are described, including field curing, windrow curing, shade curing, and mechanical curing. Key factors that affect storage life are also outlined. Different types of storage structures used in India are illustrated, including single pole, hanging, and ventilated designs.