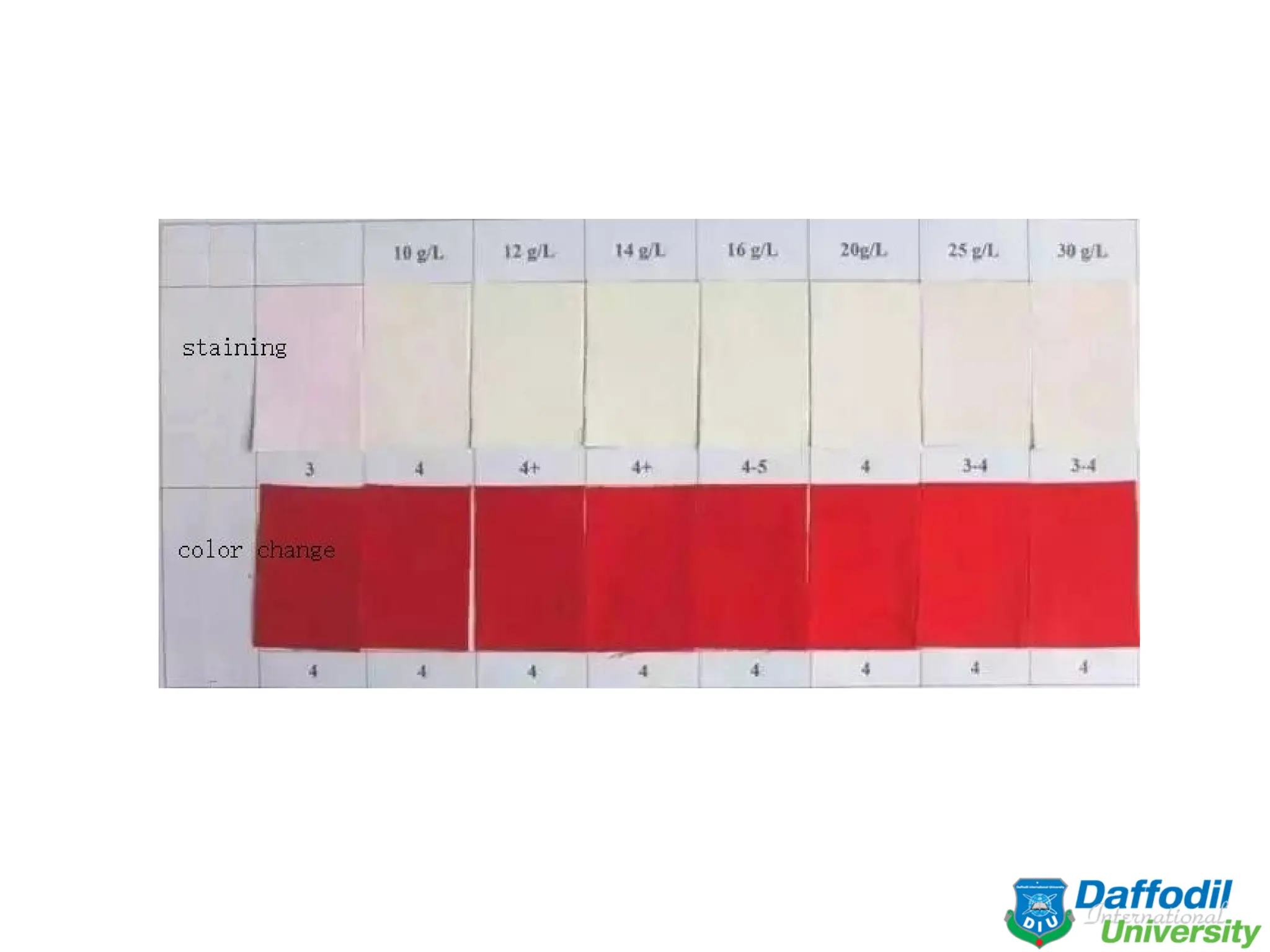

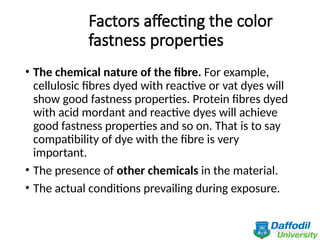

Color fastness is a crucial property of dyed textiles that measures resistance to fading or bleeding under various conditions such as water, light, and abrasion. It is assessed through several types of fastness tests, standardized by organizations like AATCC and ISO, which evaluate changes in color and staining. Factors influencing color fastness include the dye's molecular structure, bonding with the fiber, depth of shade, and the chemical nature of the fiber itself.