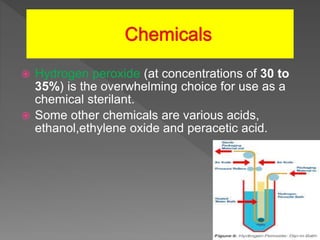

Aseptic packaging involves filling commercially sterile products into sterile containers and hermetically sealing them to prevent reinfection, resulting in shelf-stable products. The process includes sterilizing the product and packaging materials before filling, often utilizing heat, chemicals, or radiation for sterilization. Aseptic packaging offers advantages such as no refrigeration requirements, long shelf life, and enhanced nutrition but presents challenges like high installation costs and potential flavor issues.