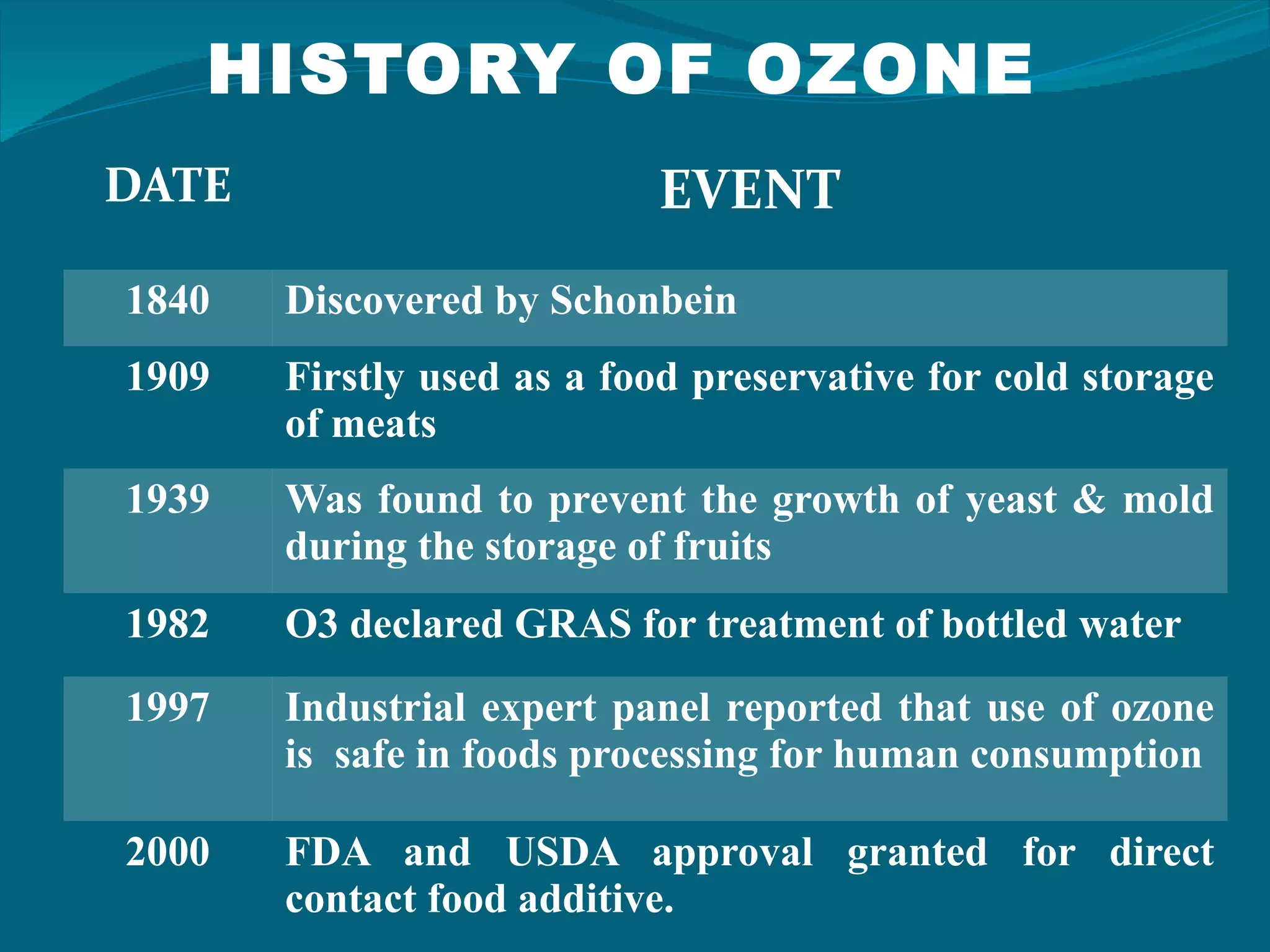

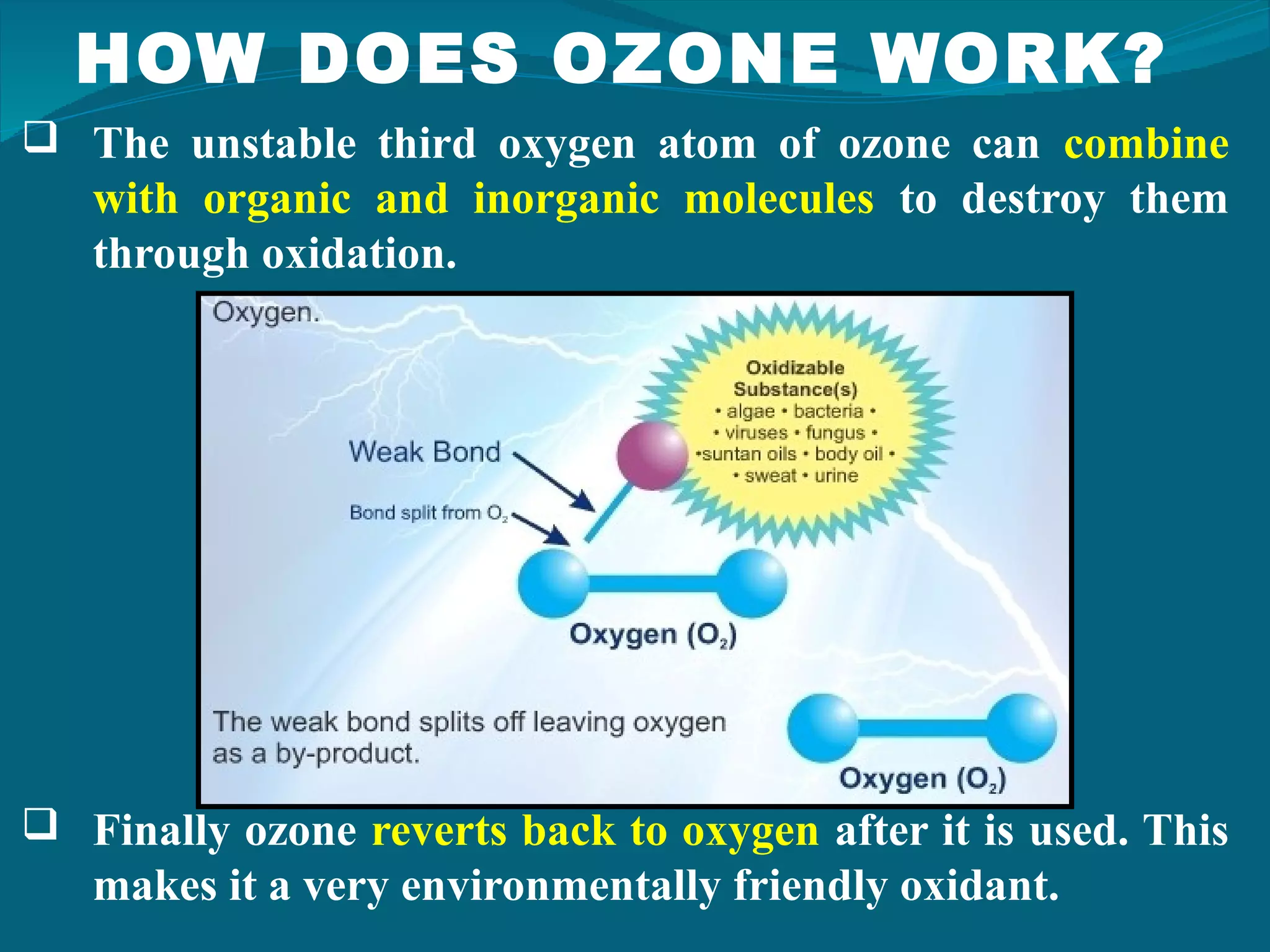

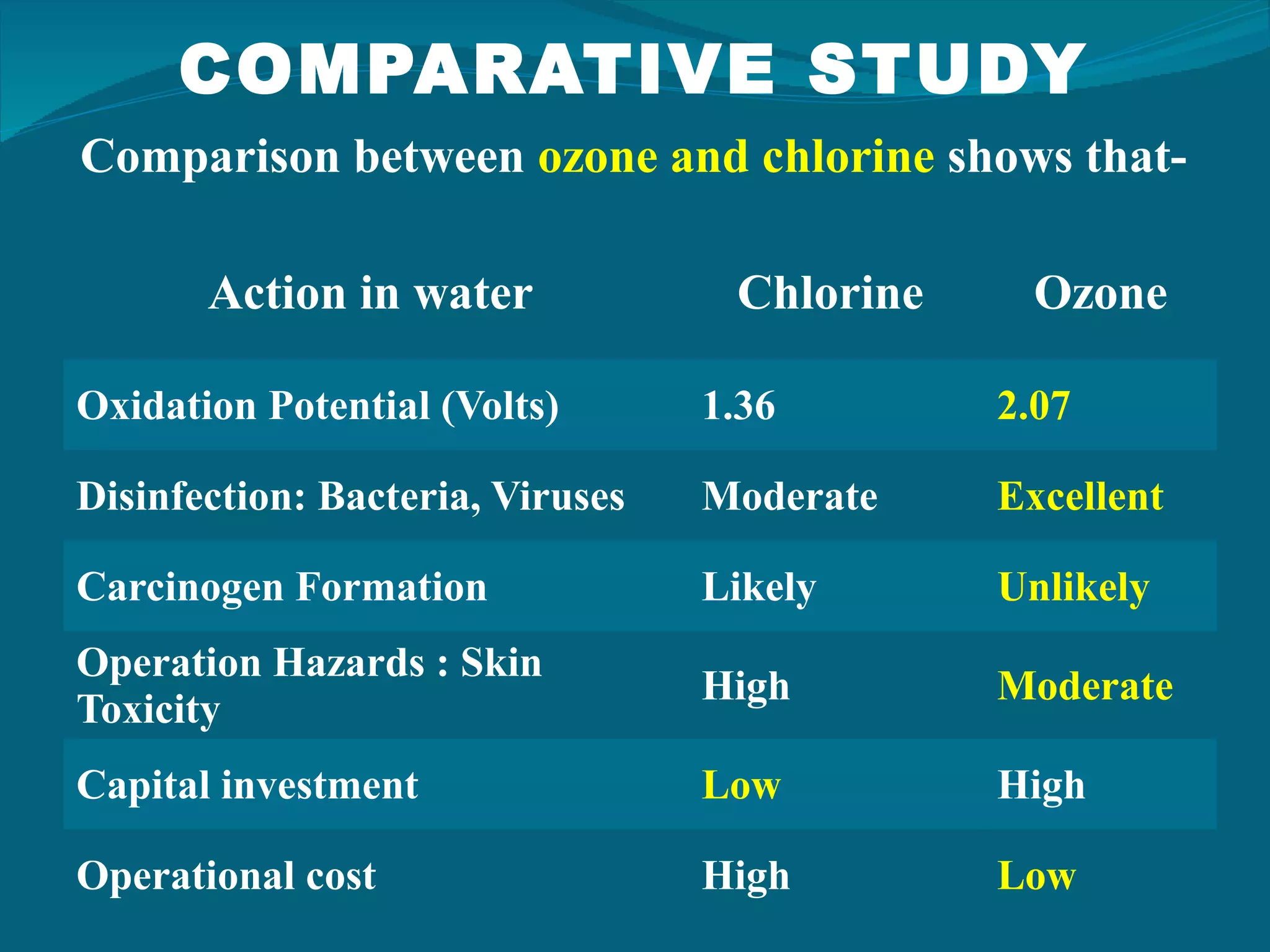

The document discusses the application of ozone in food processing, highlighting its history, production methods, and effectiveness as a powerful sanitizer. Ozone is recognized for its environmental benefits and diverse applications, including seafood processing, fruits and vegetables treatment, milling, and surface sanitation. While ozone offers advantages such as cost-effectiveness and high efficacy against pathogens, it also presents challenges such as complex installation and potential byproducts.