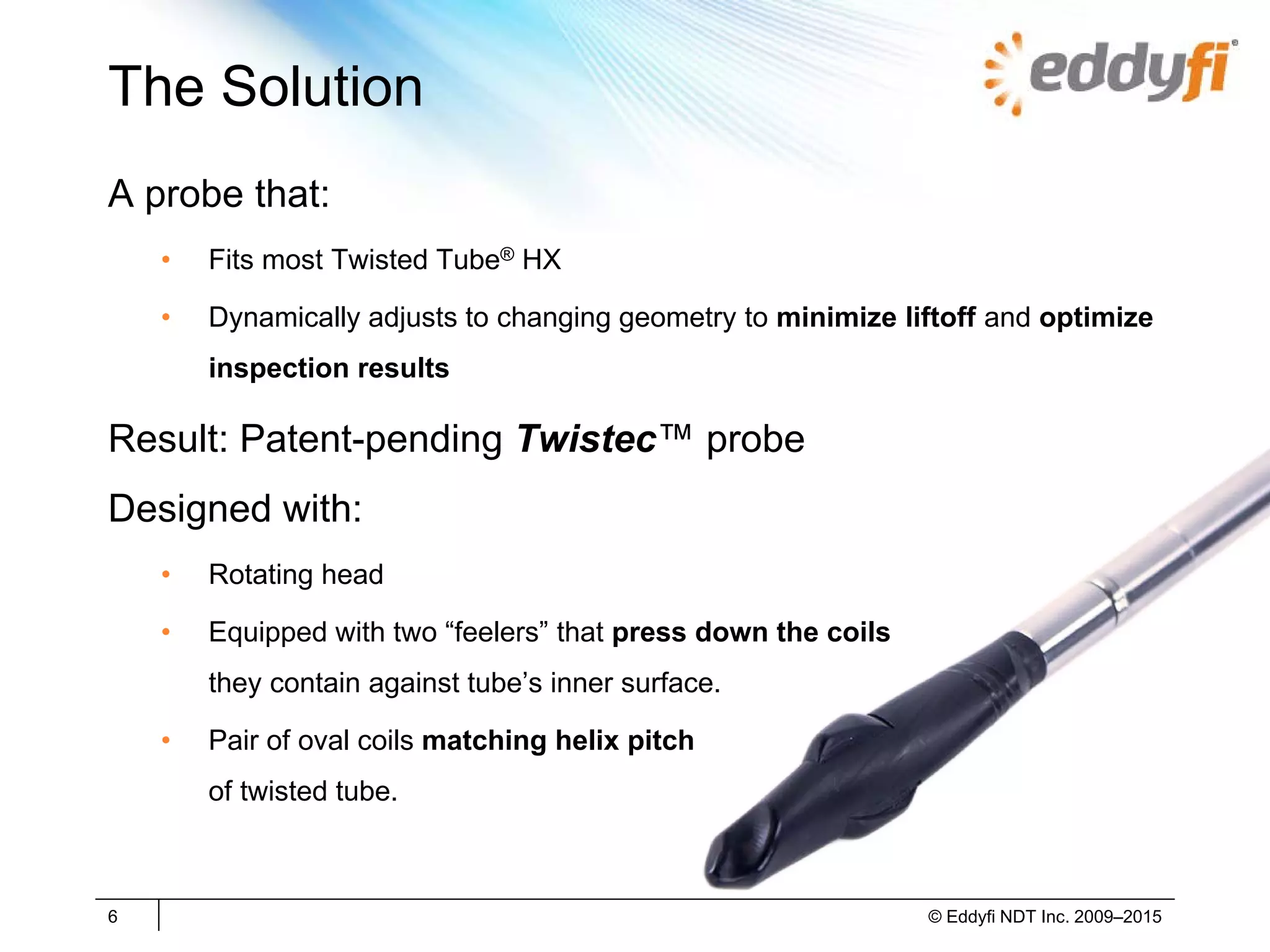

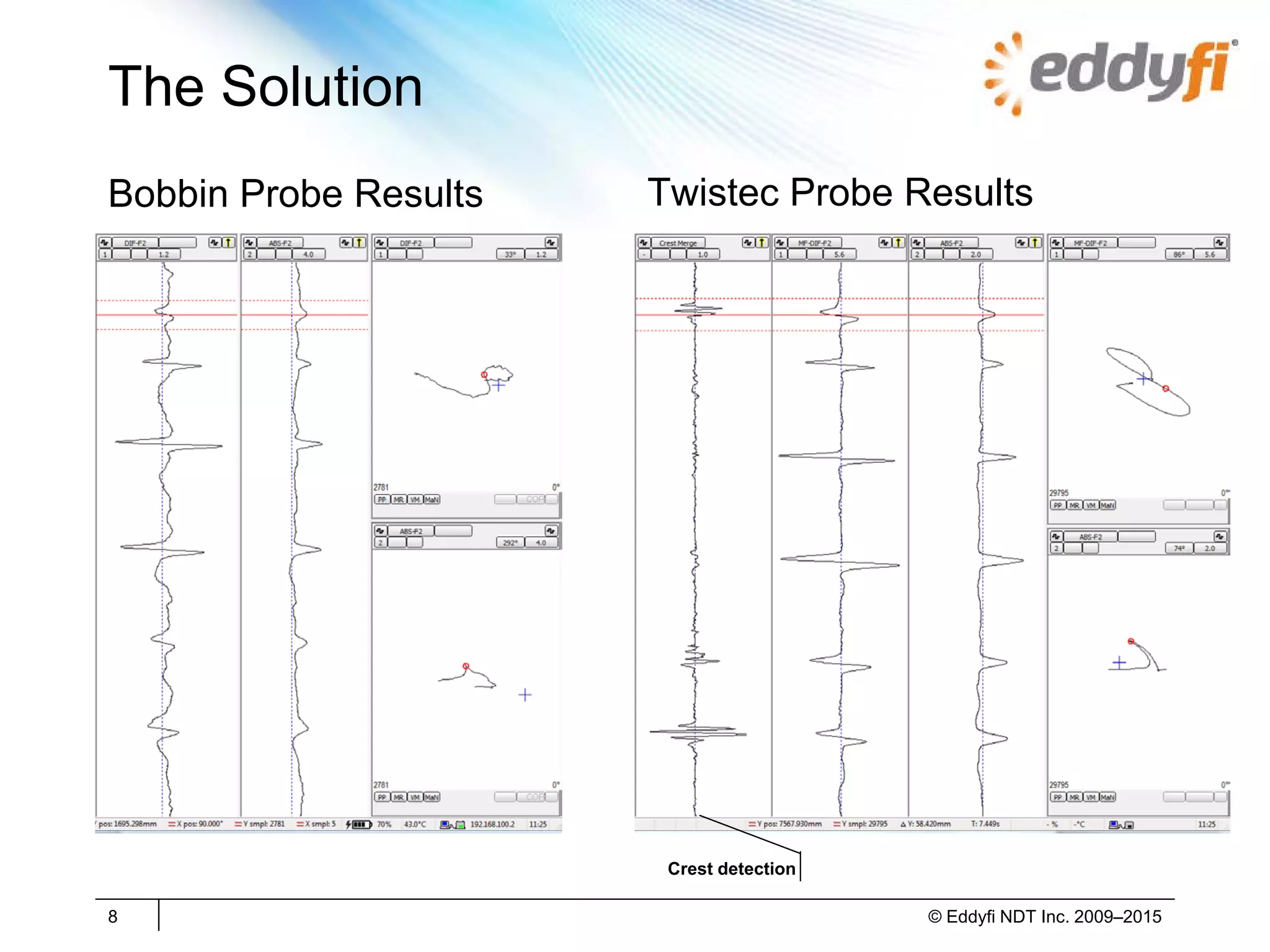

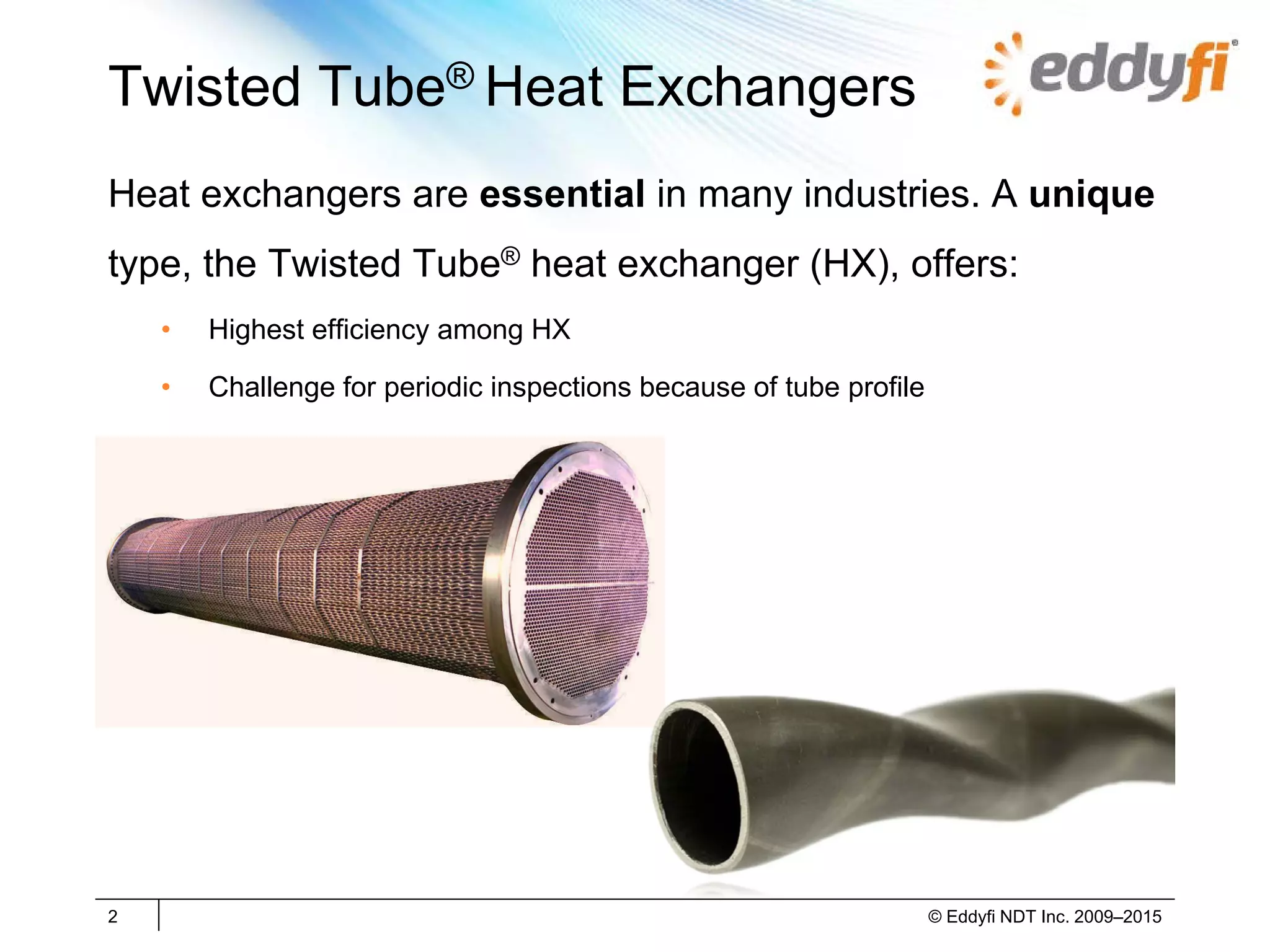

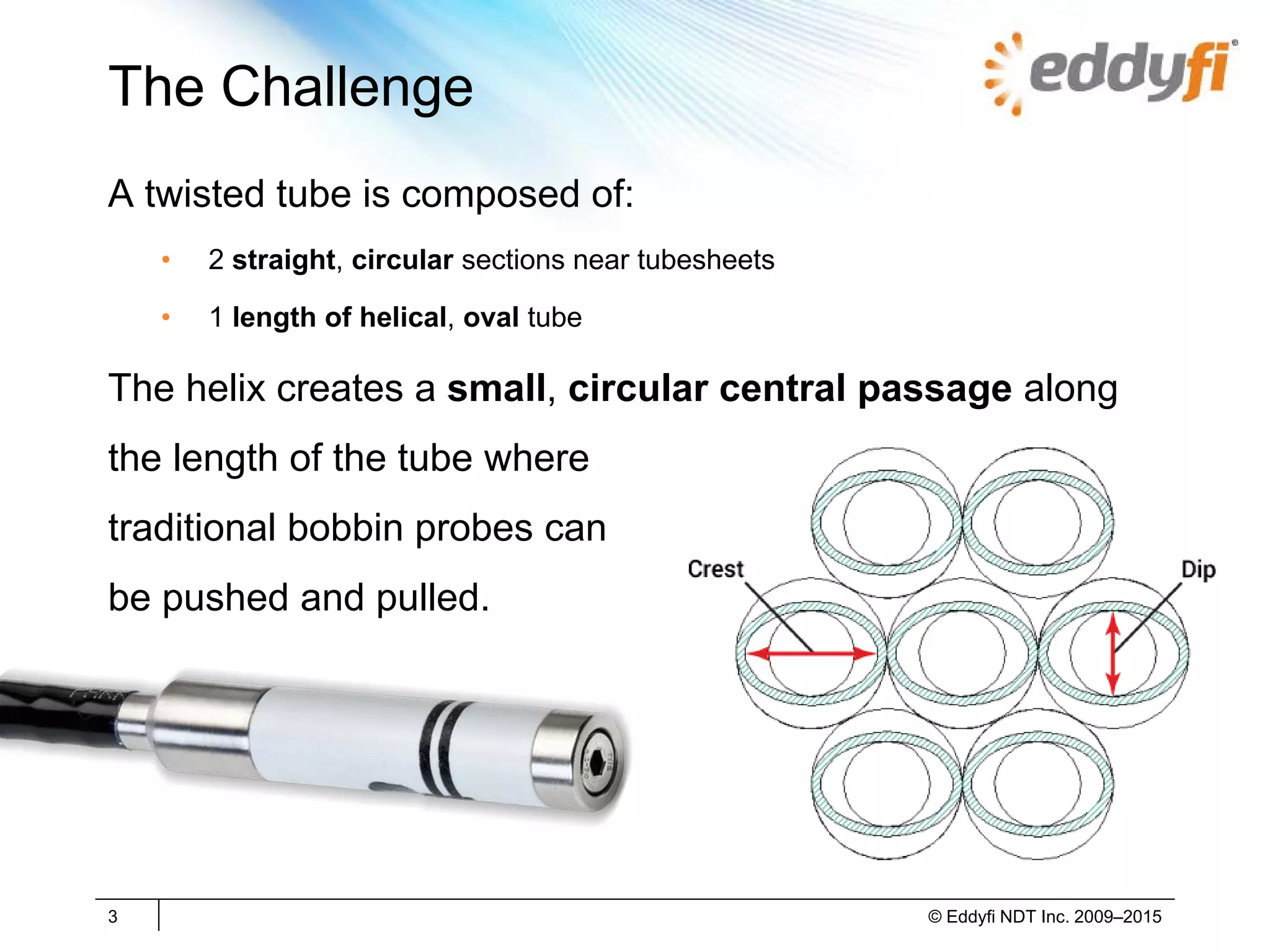

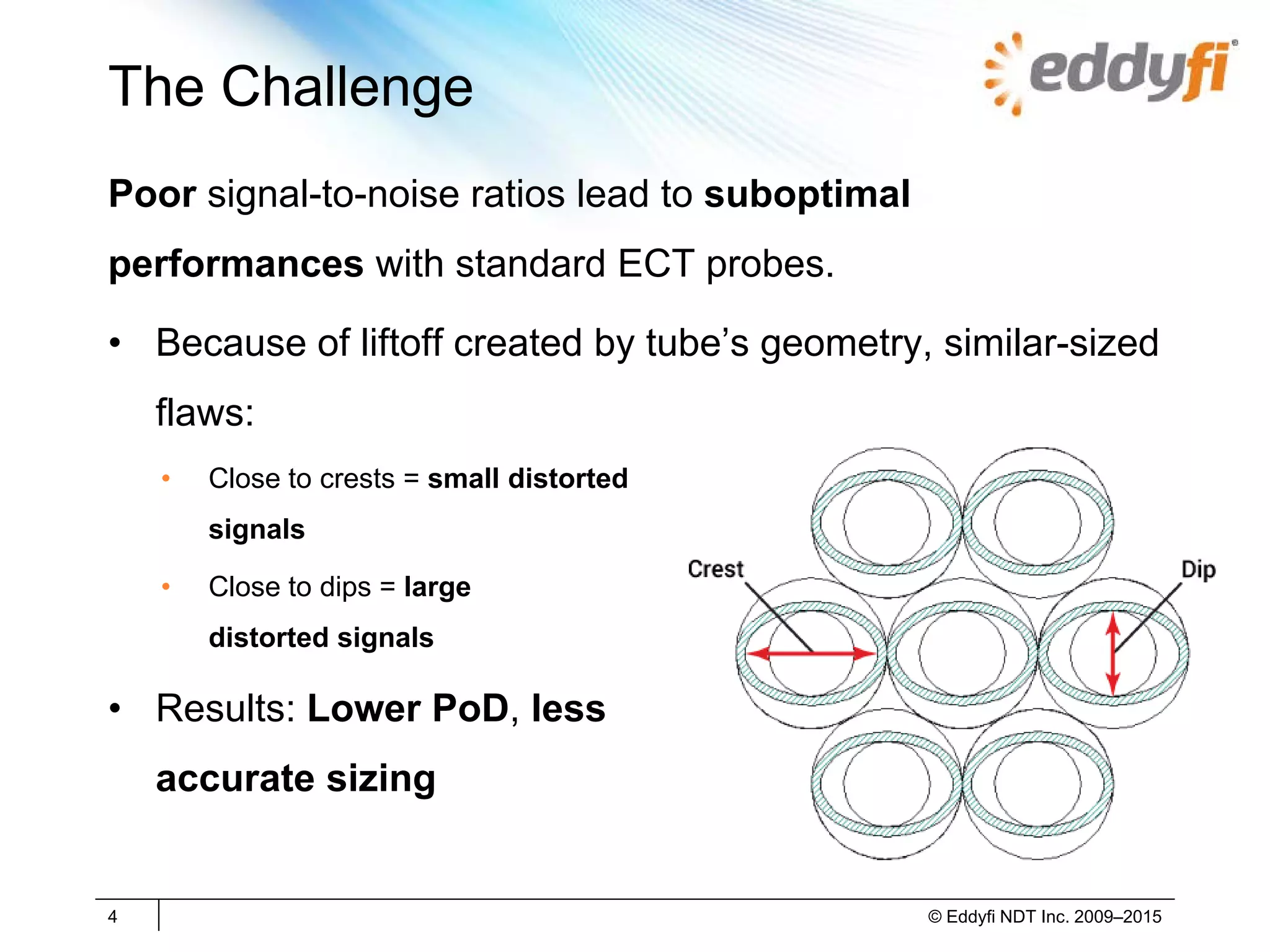

Twisted Tube® heat exchangers are efficient but present challenges for inspection due to their unique tube geometry, affecting signal quality when using standard eddy current probes. The Twistec™ probe has been developed to adapt to these geometric changes, offering enhanced inspection accuracy by minimizing liftoff and noise. This probe allows for clearer defect identification and improved results compared to traditional methods.

![The Challenge

• Common sizing method to determine flaw depth are

inaccurate because:

• Reduced sensitivity

• Large tube signal variations from flaw locations (crest/dip)

• IRIS also affected by non-linear geometry

• Reflecting echoes not perpendicular to inspected wall. Not an alternative.

• Tubes in Twisted Tube® HX come in variety of:

• Pitches

• Diameters (typical: 19.1–25.4 mm [0.75–1 in])

• Non-ferromagnetic and ferromagnetic materials

5 © Eddyfi NDT Inc. 2009–2015](https://image.slidesharecdn.com/applicationnote-twistedheatexchangertubes-20150608-150608132945-lva1-app6891/75/Twisted-Tube-Heat-Exchanger-Inspection-with-Eddy-Currents-5-2048.jpg)