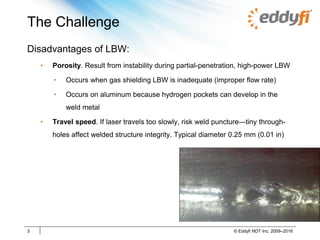

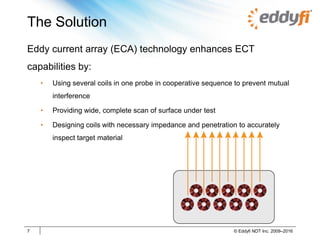

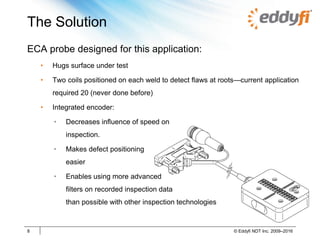

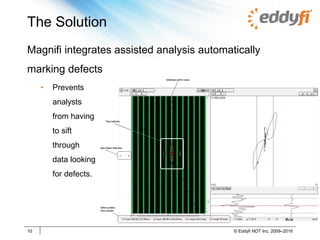

The document discusses the challenges and disadvantages of laser beam welding (LBW) in component manufacturing, including issues like porosity, high cooling rates, and difficulties in inspection using traditional methods. It highlights the advantages of using eddy current array (ECA) technology for efficient inspection of laser welds, which enhances capabilities and allows for simultaneous inspections. The ECA solution offers benefits such as rapid scanning, easy data interpretation, and improved defect identification through integrated software.