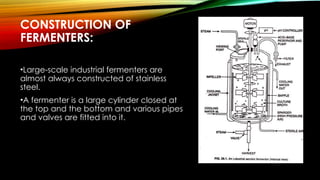

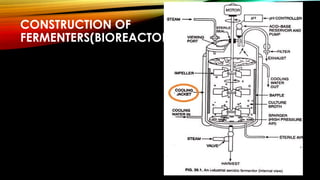

The document details the industrial production of antibiotics through fermentation processes involving genetically modified microorganisms, optimal growth conditions, and various purification methods. It outlines the steps in antibiotic production, including organism identification, fermentation, isolation, and purification, as well as the roles of different raw materials and bioreactors. Additionally, it highlights the diverse applications of microbial transformation in biotechnology, pharmaceuticals, agriculture, and environmental remediation.