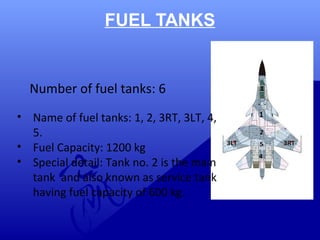

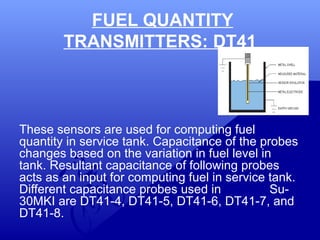

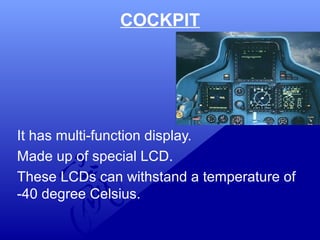

This document provides information about the fuel system of the Sukhoi SU-30 MKI aircraft. It discusses that the purpose of the aircraft fuel system is to store and deliver clean fuel to the engine under various flight conditions. The SU-30 MKI has 6 fuel tanks with a total capacity of 1200kg, including a main tank of 600kg capacity. It then describes the major components of the fuel system, including the fuel flow and metering system, fuel quantity transmitters, fuel flow transmitters, fuel quantity unit, fueling control panel, electronic transducer unit, and semiconductor relay control unit. The cockpit has multi-function displays that can withstand high and low temperatures and impacts.