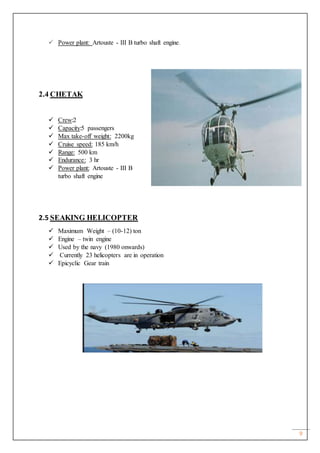

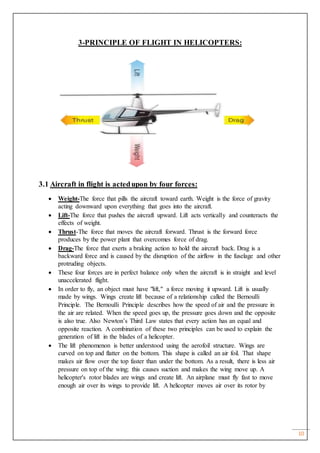

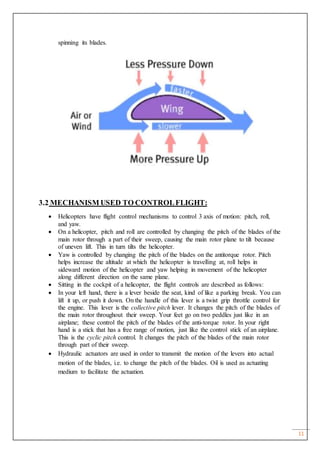

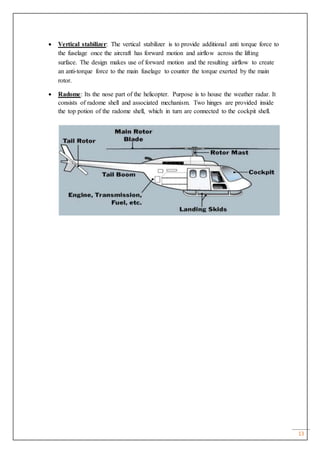

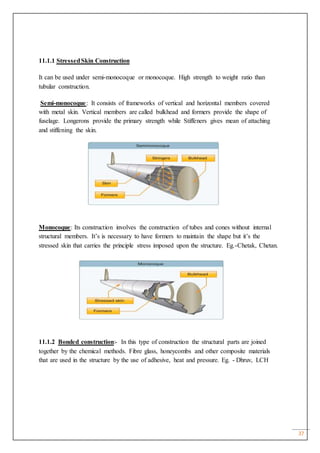

This document provides an overview of Hindustan Aeronautics Limited (HAL) and their Helicopter Division in Bengaluru. It discusses the types of helicopters manufactured by HAL, including the Advanced Light Helicopter (ALH)-Dhruv, its variants (MK1-MK4), and the Light Utility Helicopter (LUH). It also outlines the history of HAL's helicopter manufacturing, from initial licenses with French companies to developing indigenous designs like the Dhruv and new helicopters like the Rudra, LCH, and LUH. The divisions involved in manufacturing, maintenance, repair, overhaul, training, and research and development of helicopters are mentioned.