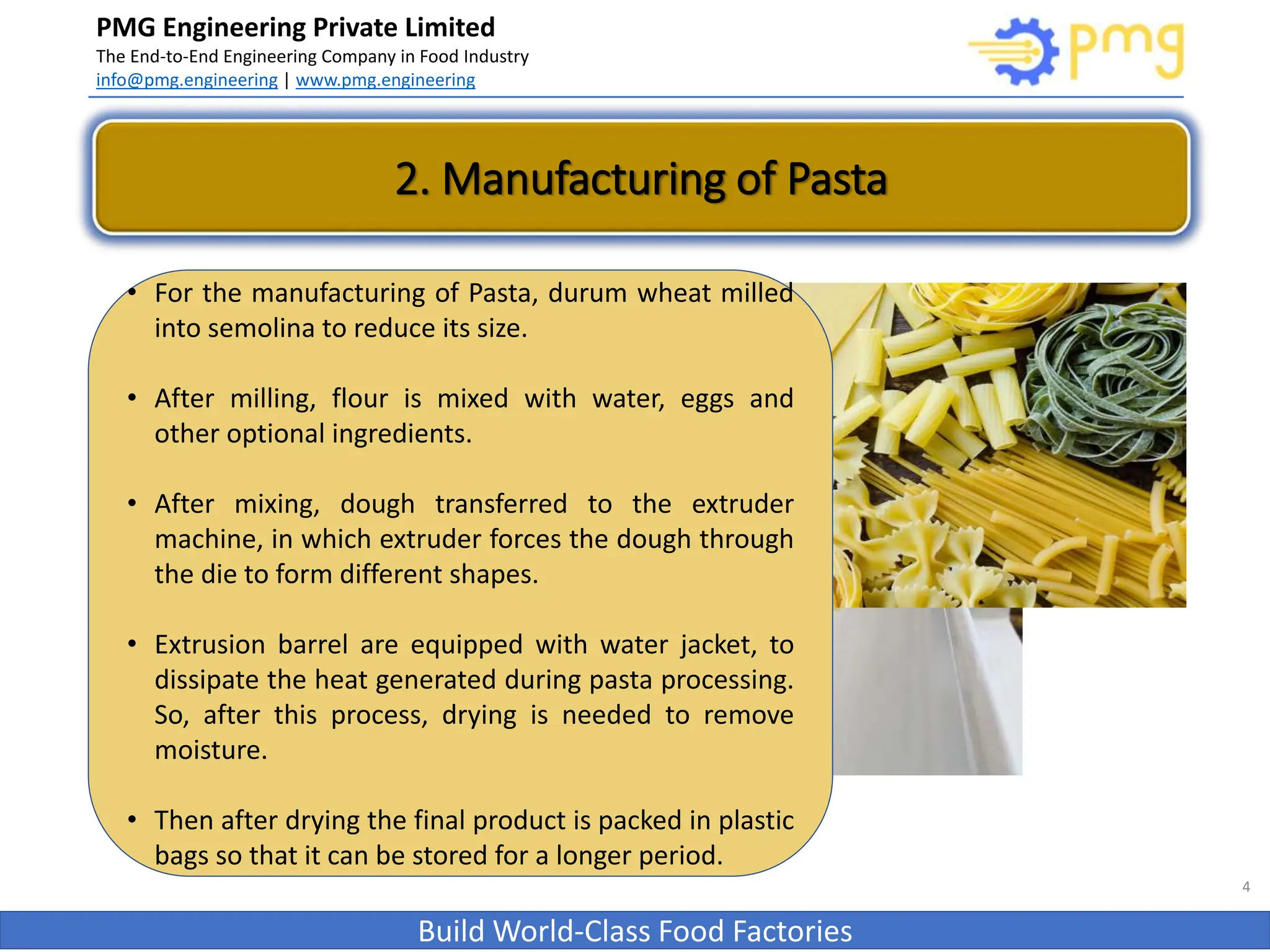

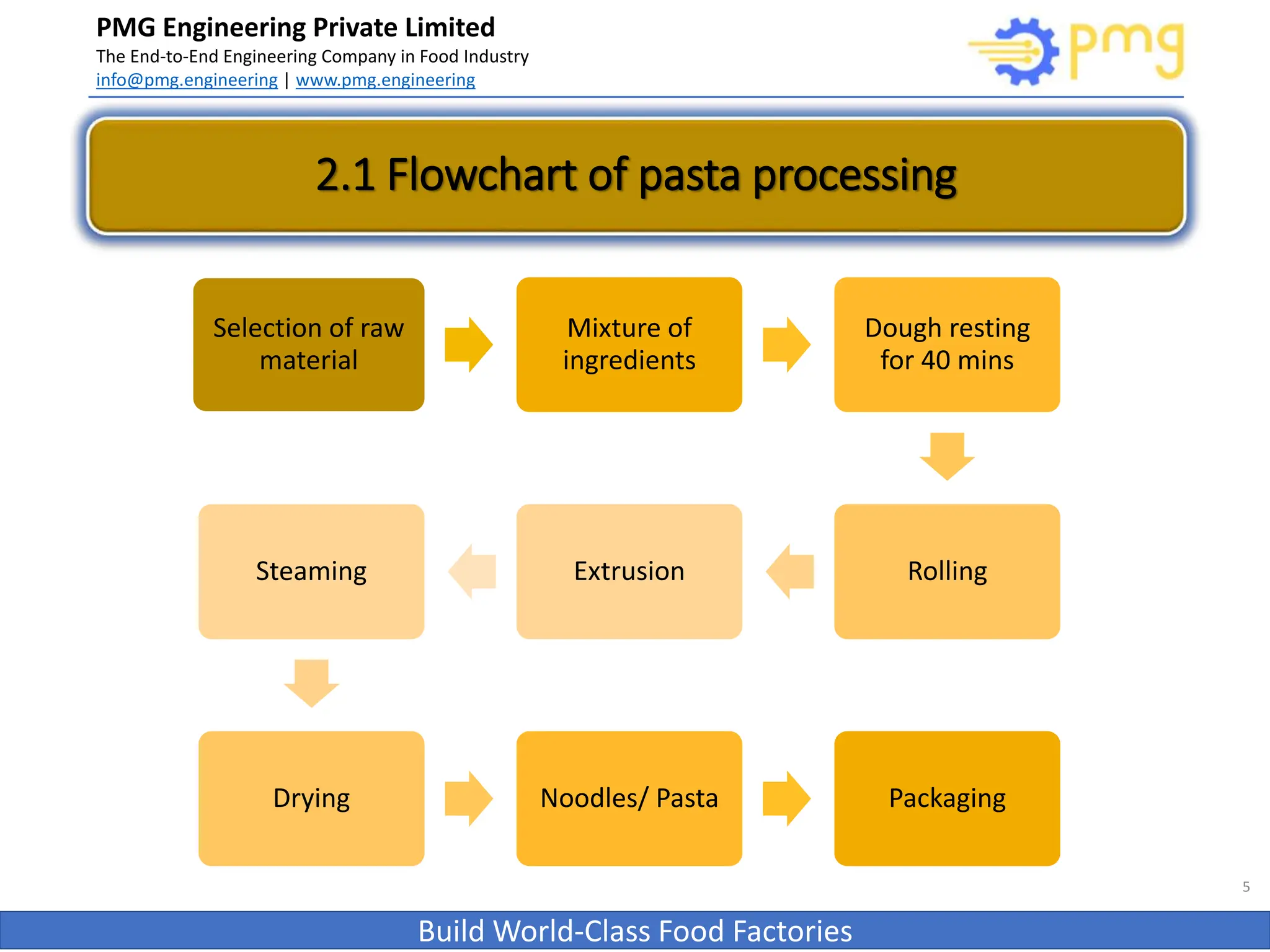

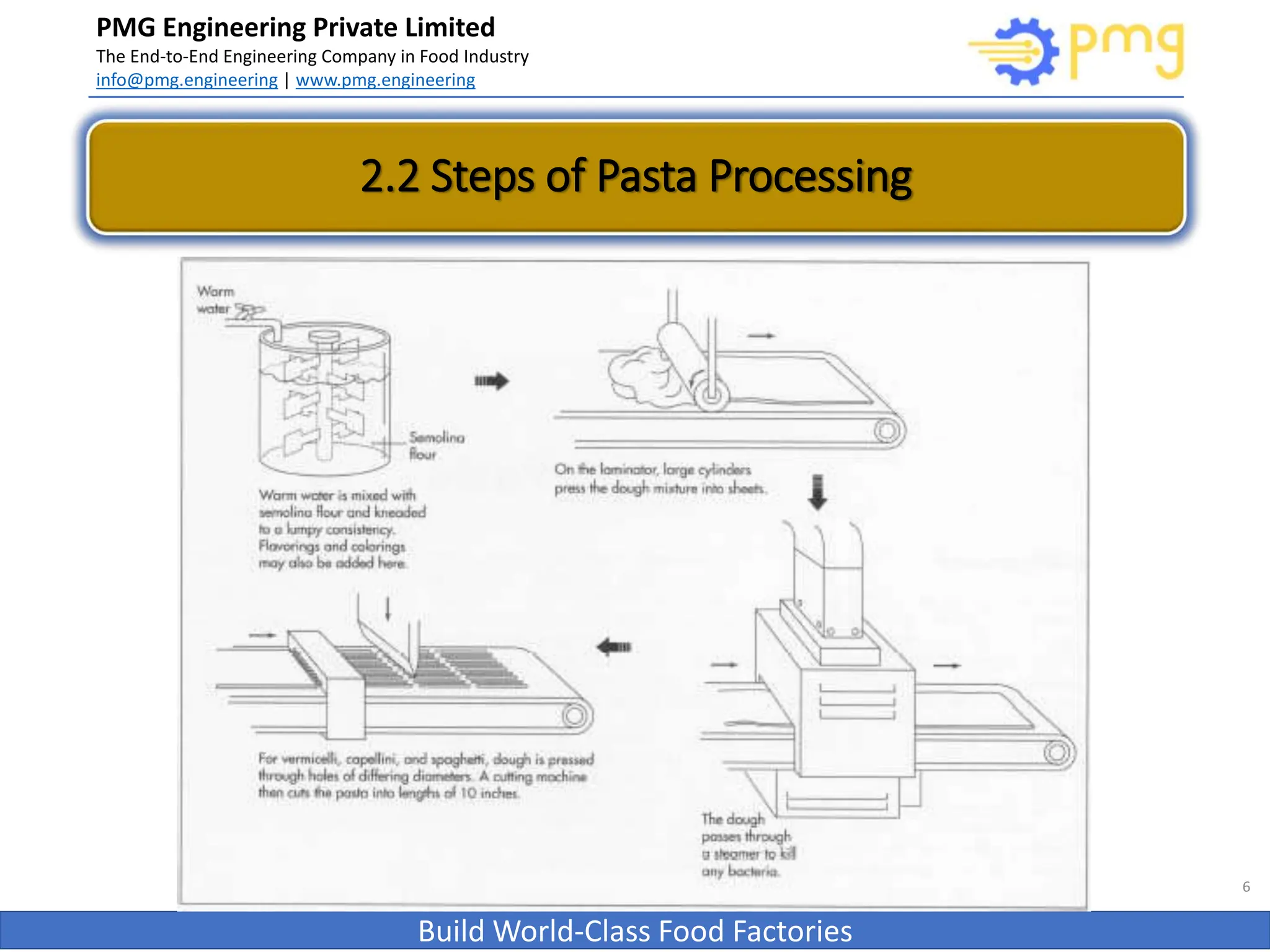

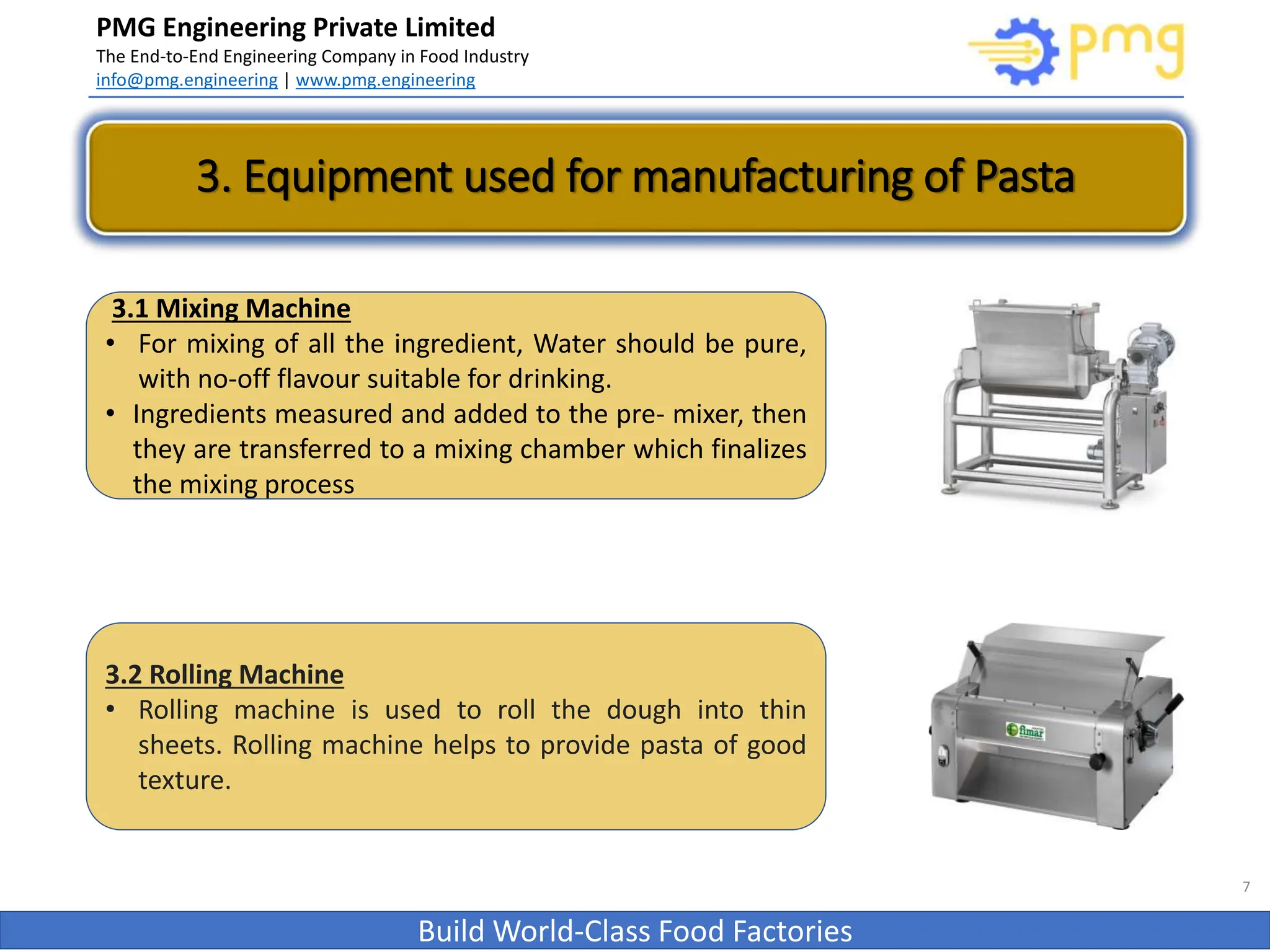

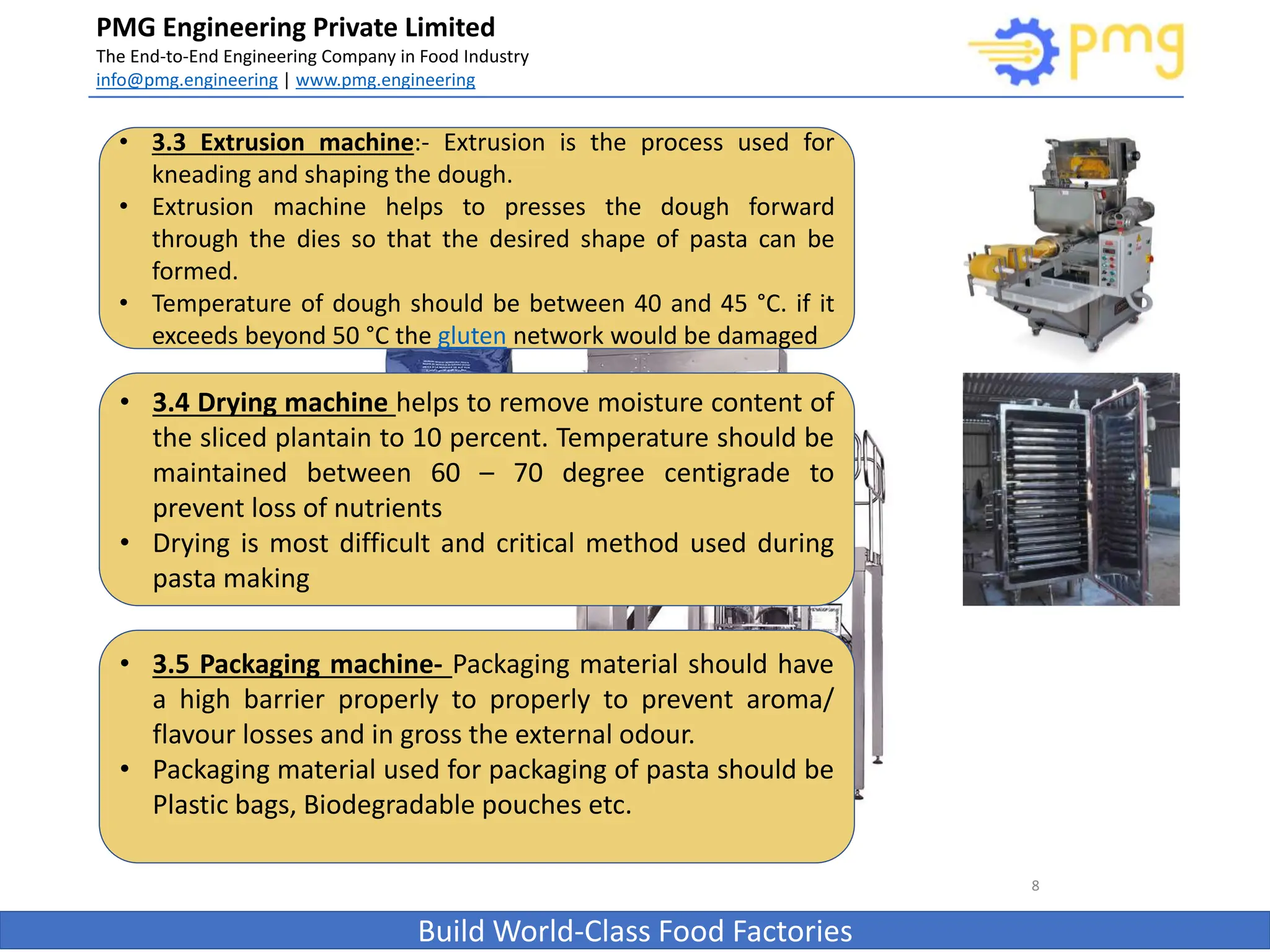

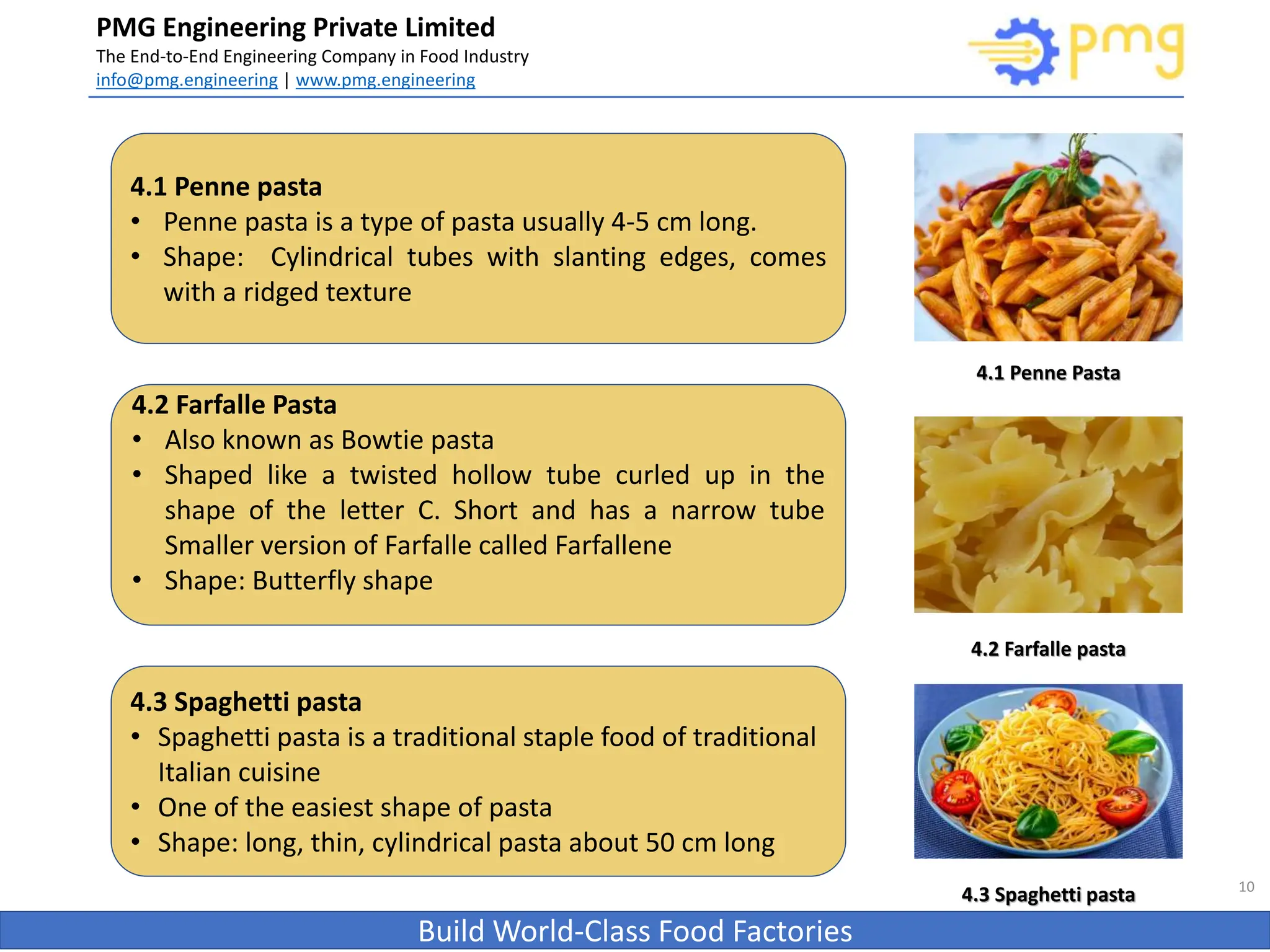

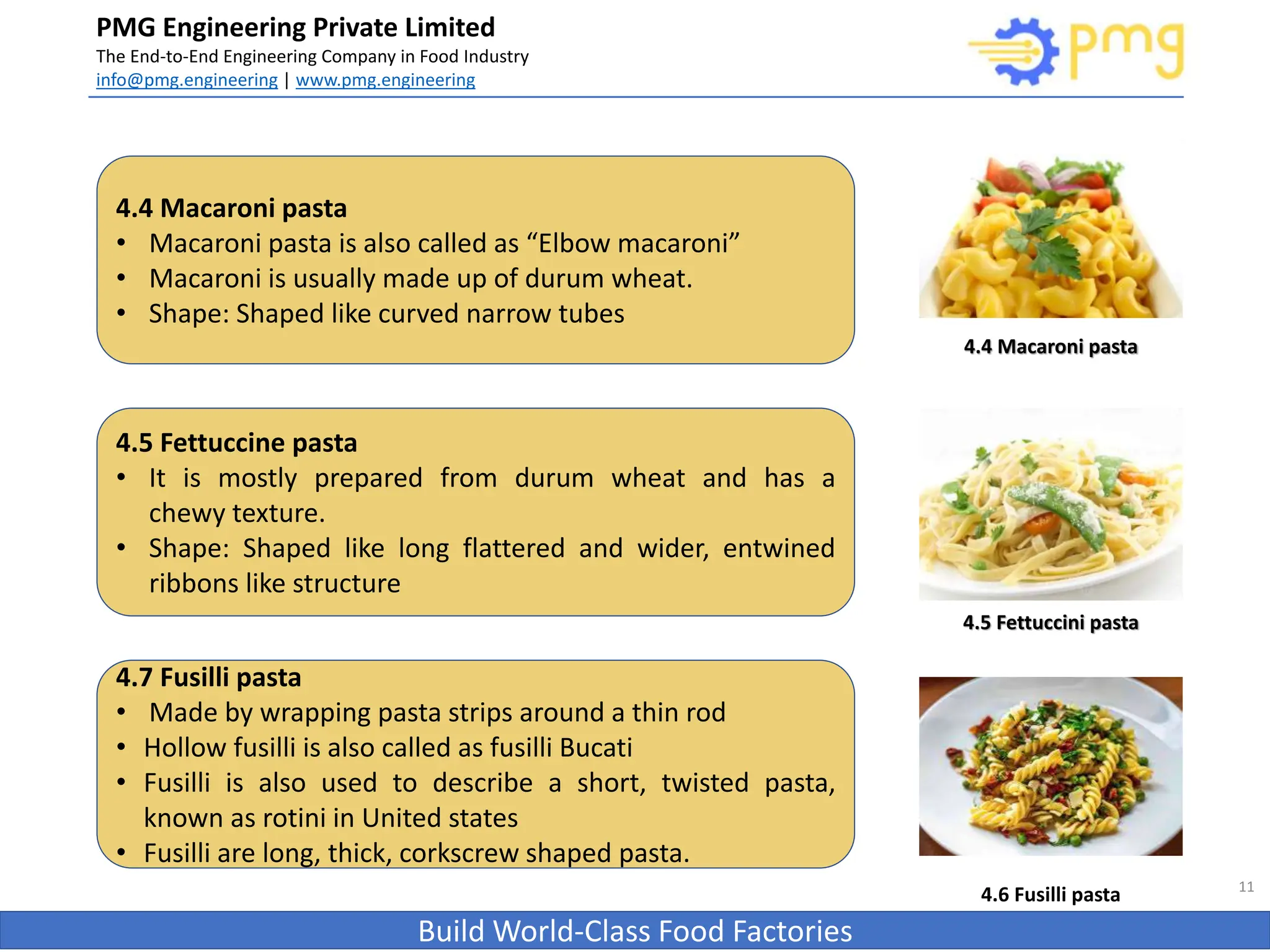

PMG Engineering Private Limited specializes in the end-to-end engineering of food factories, particularly focusing on pasta manufacturing. The document details the pasta manufacturing process, including equipment used, various types of pasta, and their shelf life. Key aspects covered include the ingredients, processing steps, and an overview of the different pasta shapes available.