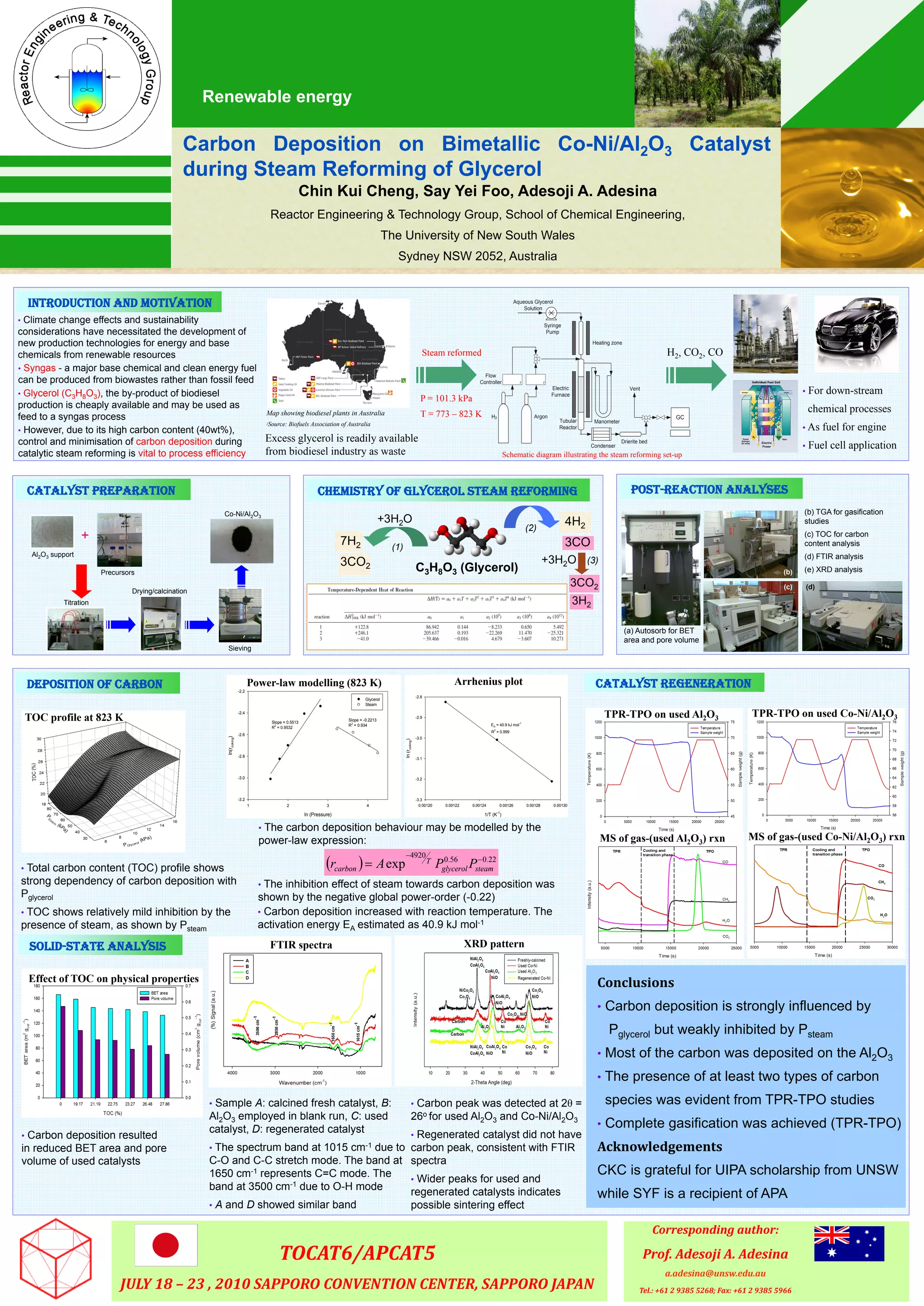

This document discusses a study on carbon deposition during steam reforming of glycerol using a bimetallic Co-Ni/Al2O3 catalyst. Glycerol is a byproduct of biodiesel production that can be converted to syngas via steam reforming, but carbon deposition must be minimized for process efficiency. The study examines steam reforming of an aqueous glycerol solution over a temperature range of 773-823K using a tubular reactor. Various characterization techniques are used to analyze the catalyst before and after reaction, including thermal gravimetric analysis, total organic carbon content analysis, Fourier transform infrared spectroscopy, and X-ray diffraction.