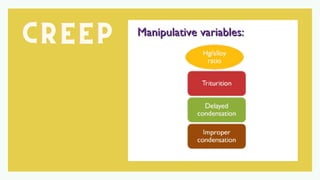

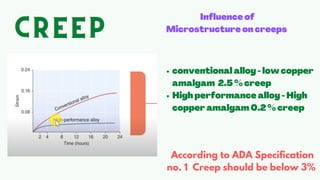

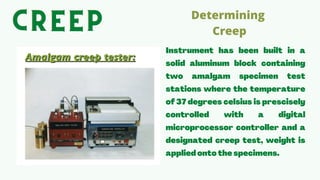

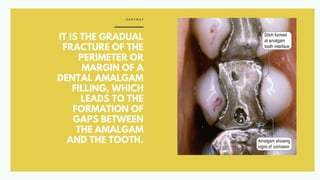

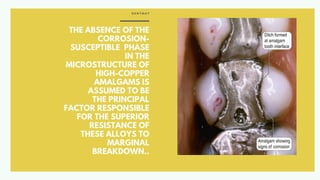

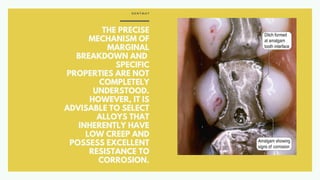

This document discusses creep and marginal deterioration of dental amalgam. It defines creep as the time-dependent plastic strain of a material under static load. Creep can be caused by the continued setting expansion of amalgam, formation of corrosion products, mastication, or thermal expansion during eating hot foods. Higher copper amalgam has lower creep around 0.2% compared to 2.5% for conventional alloy. Marginal breakdown is the gradual fracture of the perimeter of a dental amalgam filling, leading to gaps between the amalgam and tooth. Techniques to prevent marginal breakdown include correct carving of excess amalgam and burnishing the margins before and after carving. Alloys with lower creep values below 1% generally experience less marginal breakdown than higher-cre