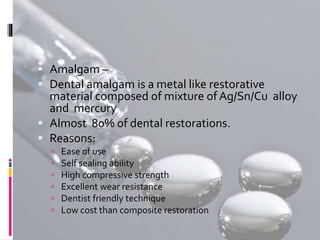

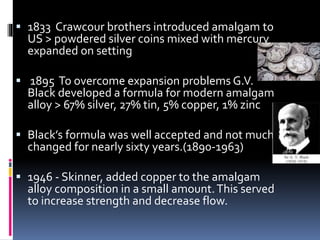

This document provides an overview of dental amalgam, including its:

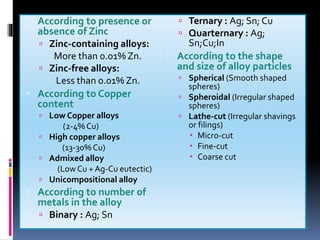

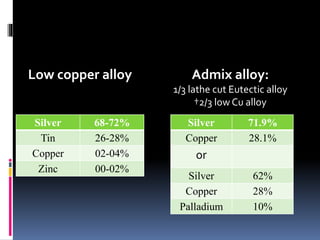

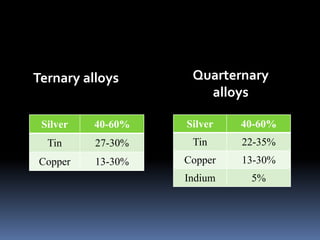

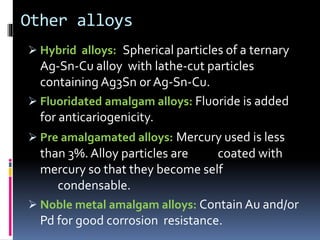

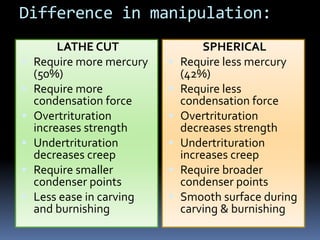

- Classification based on composition and particle shape

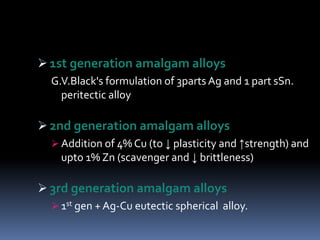

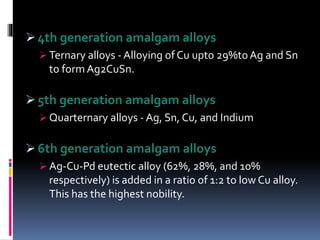

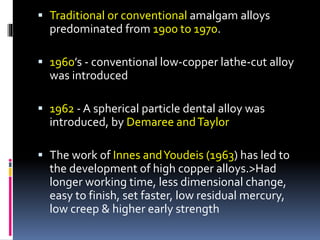

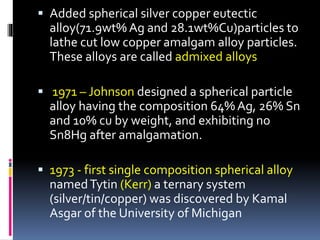

- Generations and typical compositions

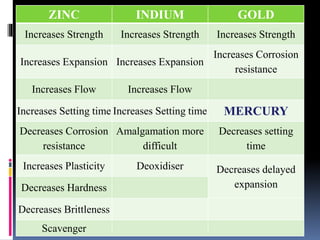

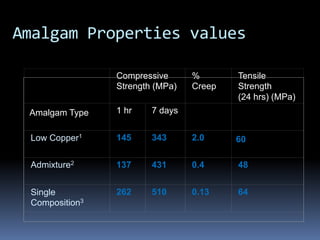

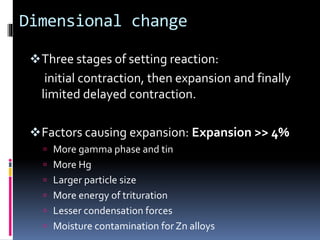

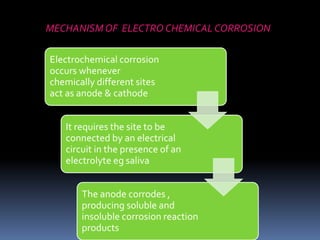

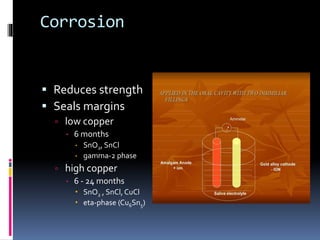

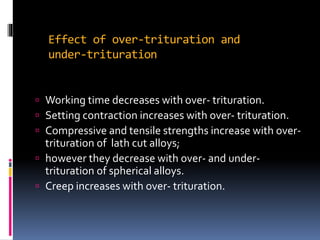

- Properties including strength, creep, corrosion resistance

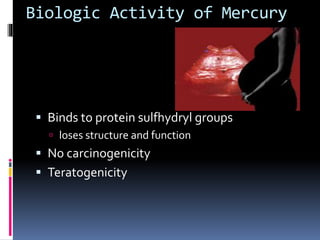

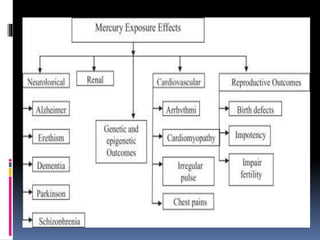

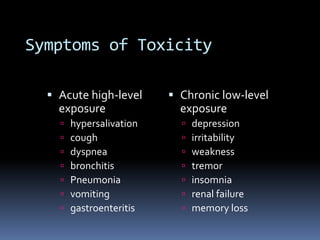

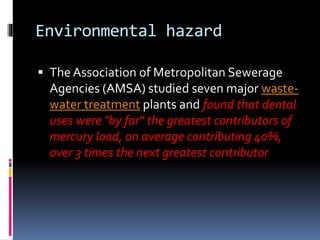

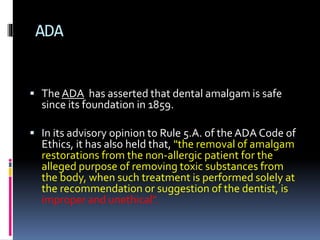

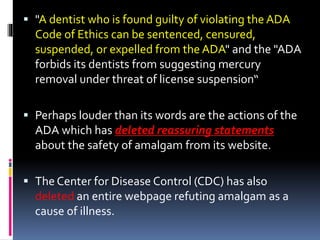

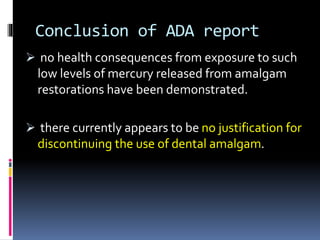

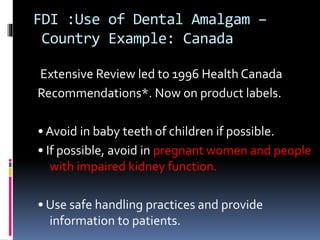

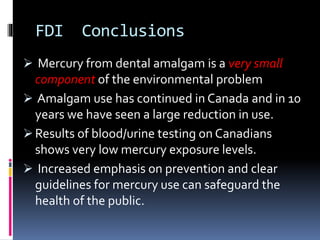

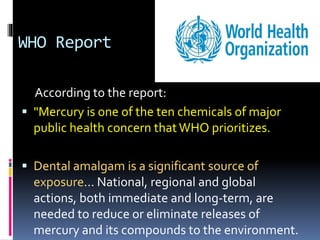

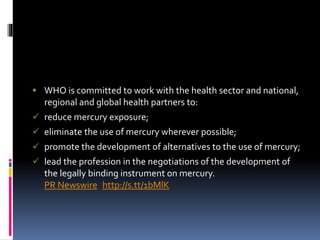

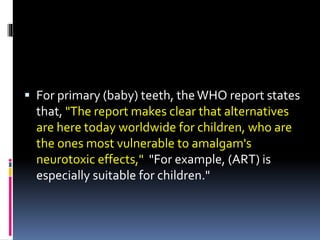

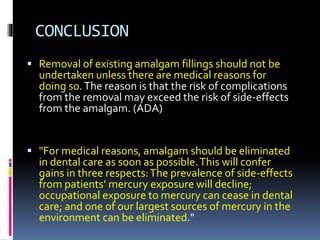

- Toxicity and mercury levels

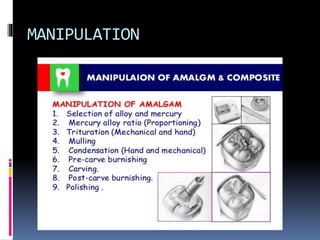

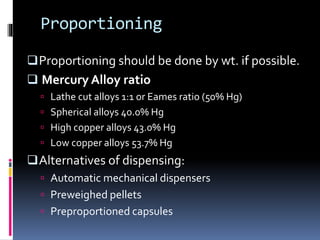

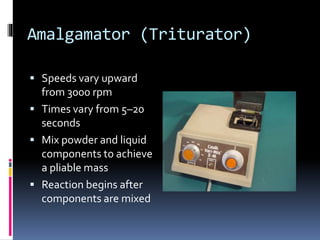

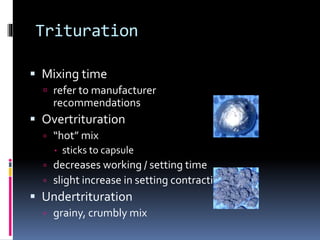

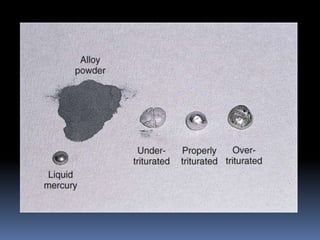

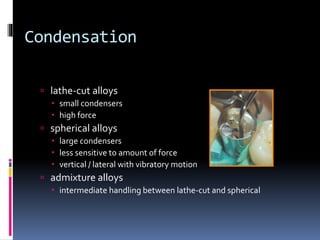

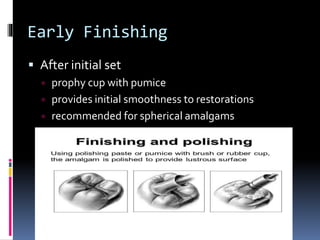

- Manipulation techniques for mixing, condensing, and finishing amalgam restorations

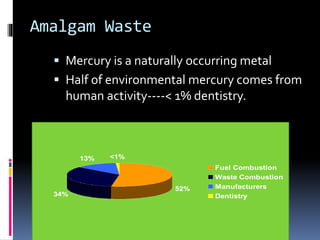

- Status and concerns about mercury levels from dental offices