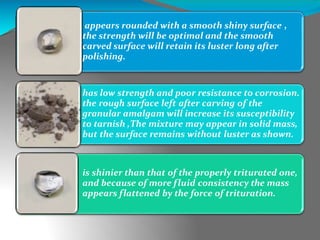

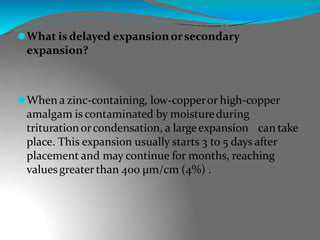

Dental amalgam is an alloy used in dental fillings that is created by mixing mercury with silver, tin, and copper. The document discusses the composition of dental amalgam alloys, including low-copper, high-copper, and gallium-based alloys. It also covers the properties, clinical use, and safety of dental amalgam, including how it is manipulated during dental procedures, its strength, creep, and corrosion resistance over time. The typical service life of a dental amalgam filling before needing repair or replacement is 7 to 15 years.