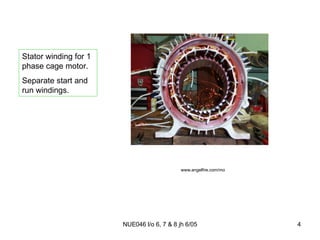

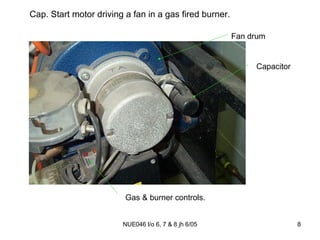

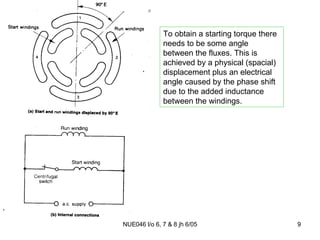

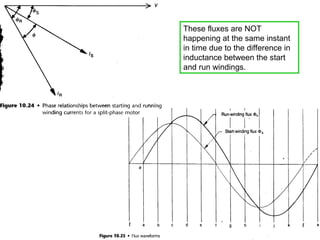

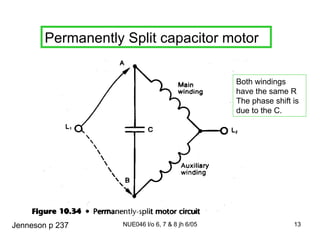

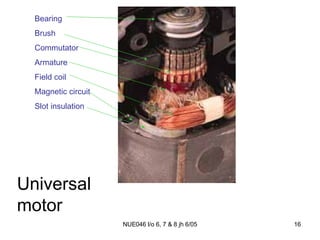

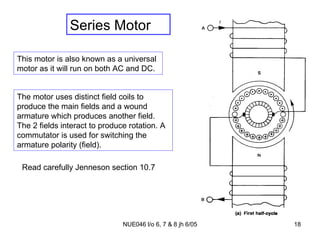

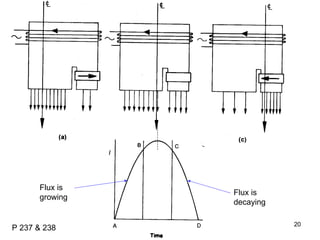

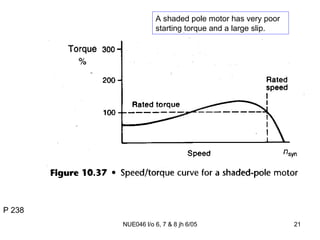

The document discusses different types of single-phase induction motors, including split phase, shaded pole, capacitor start, and universal motors. It provides details on how each type of motor works, such as how split phase motors use a start and run winding to generate a phase shift for starting torque. Capacitor start motors are also described as having high starting torque and good speed regulation. Universal motors are noted as being able to run on both AC and DC power.