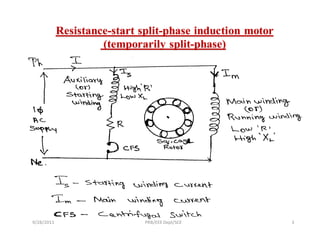

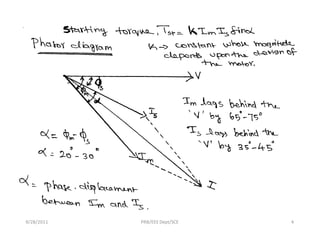

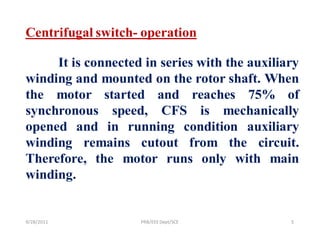

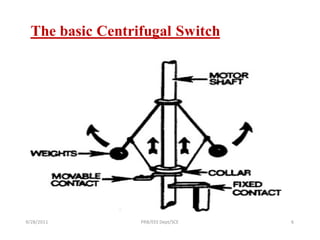

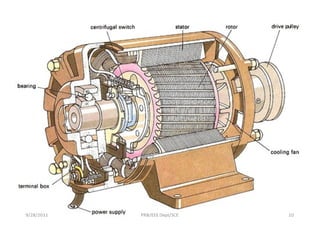

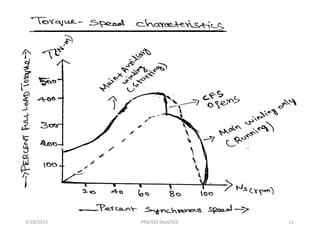

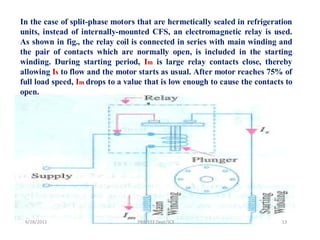

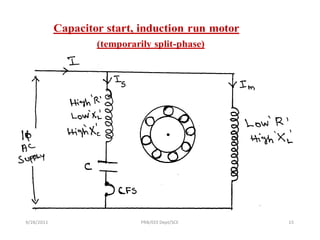

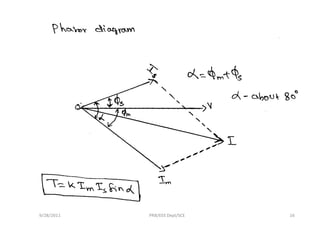

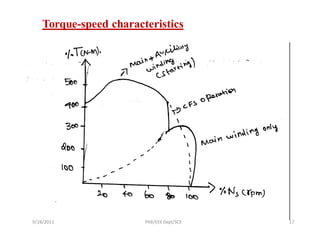

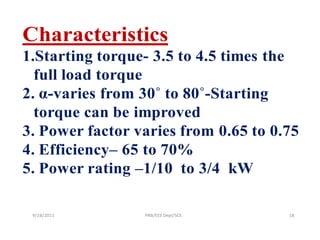

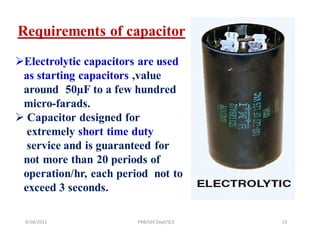

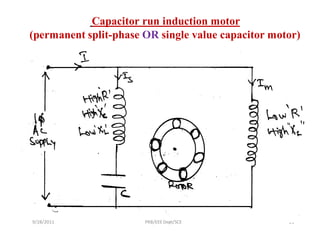

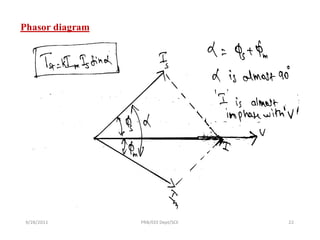

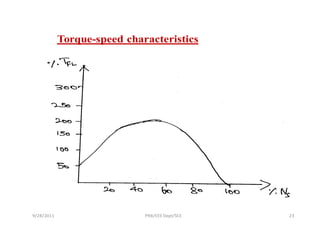

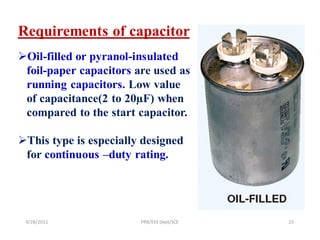

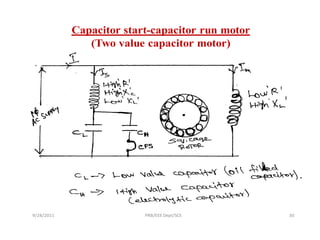

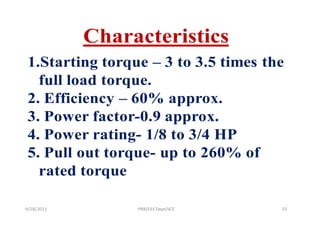

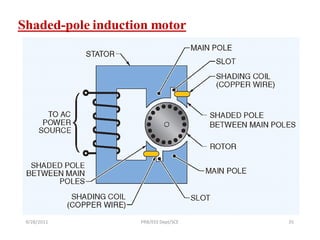

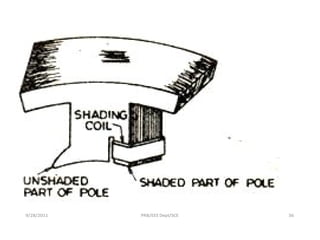

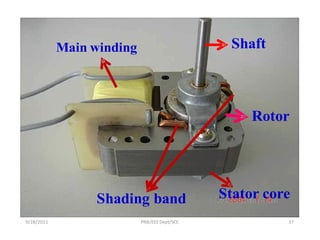

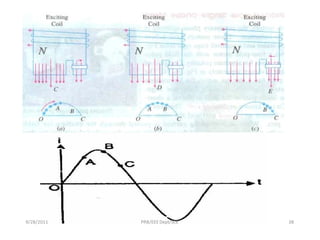

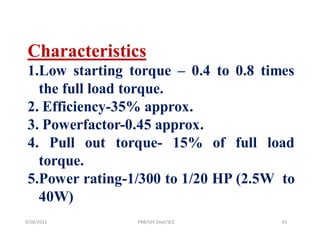

The document classifies and describes different types of single-phase induction motors based on their starting methods: (1) split-phase induction motors use an auxiliary winding and centrifugal switch, (2) capacitor motors use an auxiliary winding and capacitor(s), and (3) shaded-pole motors use a shading coil to produce a rotating magnetic field. Each type has different characteristics including starting torque, efficiency, and applications.