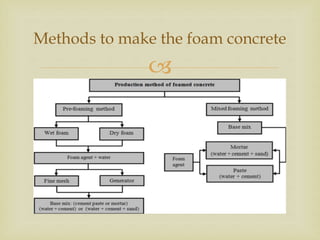

This document summarizes and compares aerated lightweight concrete types foamed concrete and autoclaved aerated concrete (AAC). It discusses that foamed concrete is produced through pre-foaming or mixed foaming methods using a foam agent to produce air bubbles. AAC uses aluminium powder as a foaming agent which reacts to produce gas bubbles during curing. The document outlines the raw materials, production processes, properties and advantages of both concrete types including their strength, density, thermal and sound insulation qualities.