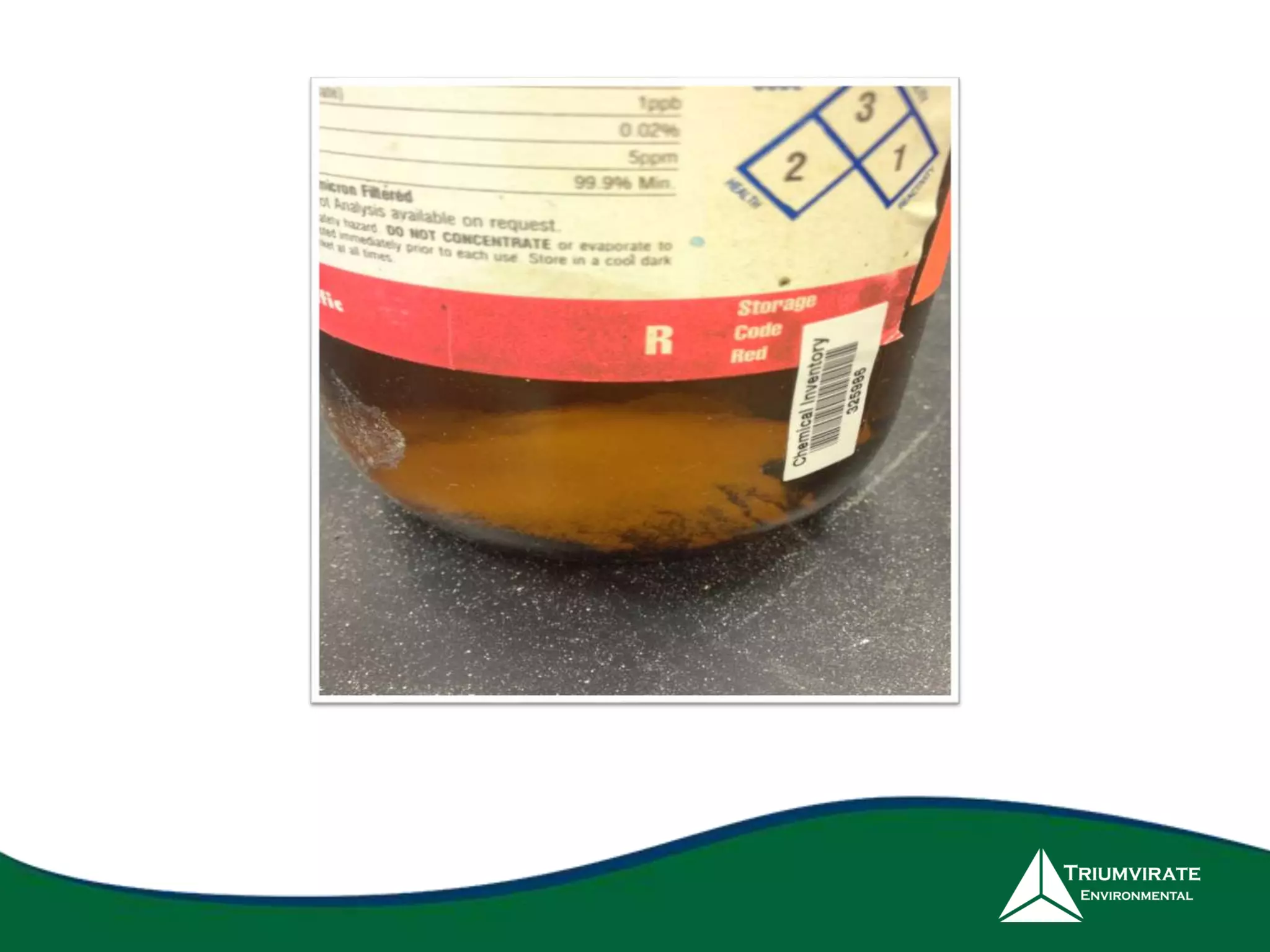

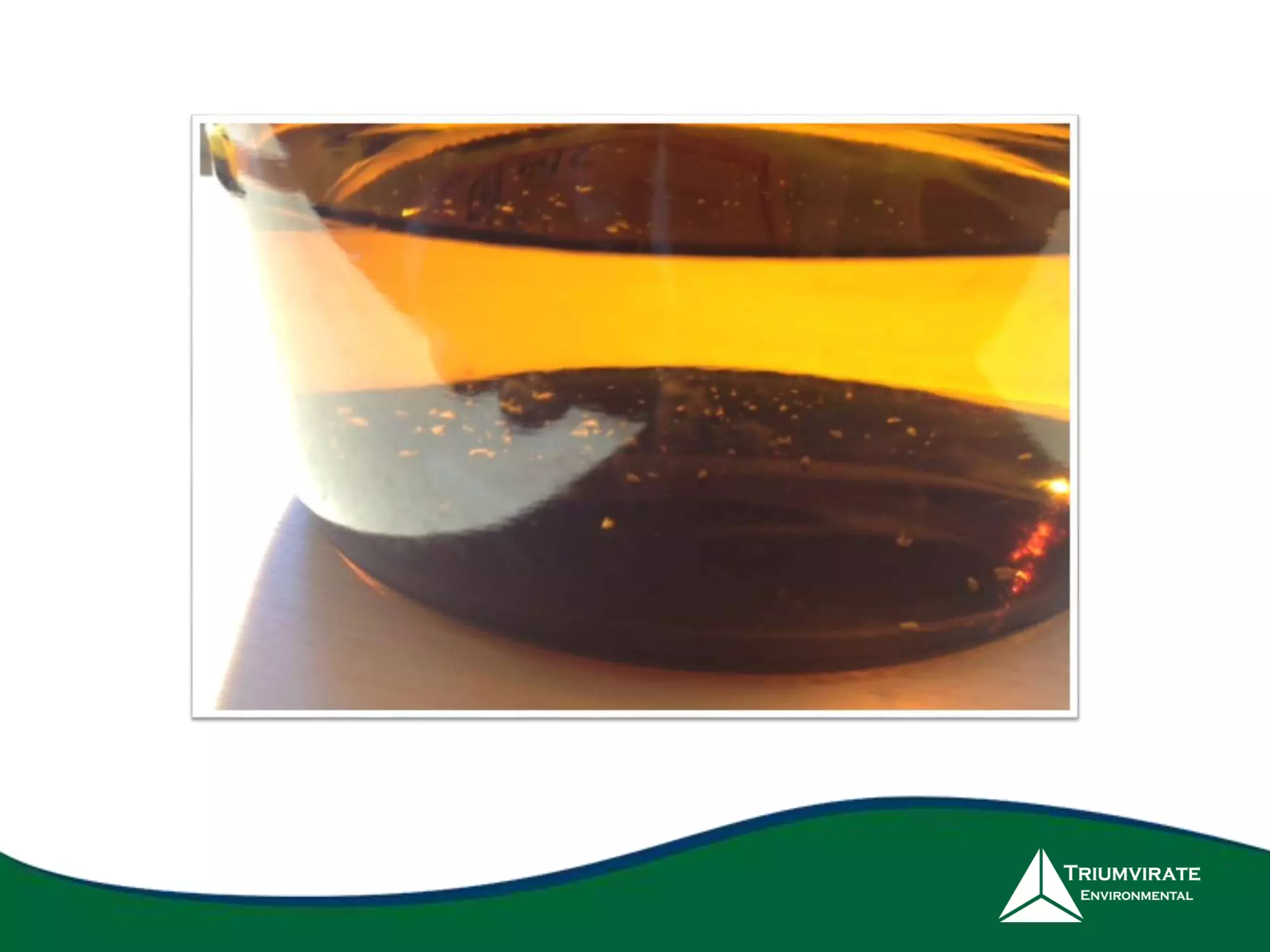

The webinar, presented by Ted Dubiel, focuses on the hazards and management of peroxide-forming chemicals, highlighting their risk due to explosive potential and the importance of proper handling and oversight. Key points include the need for structured management programs, adherence to safety regulations, and the development of standard operating procedures (SOPs) for storage and disposal to mitigate accidents. Regular inspections and communication with lab personnel about safety measures are crucial for preventing incidents related to high hazard chemicals.