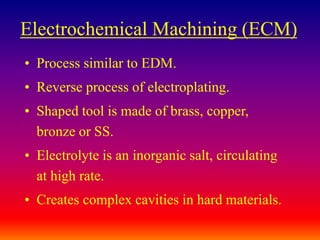

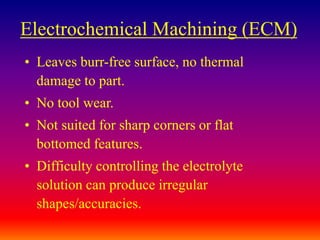

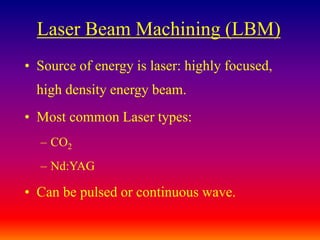

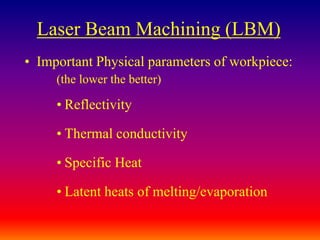

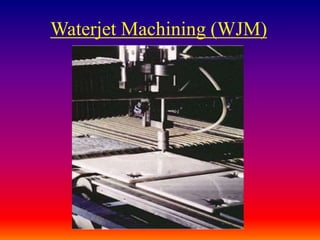

Non-traditional machining processes like EDM, ECM, laser beam machining and waterjet machining were developed to machine materials that cannot be processed through traditional methods due to limitations such as high hardness, complex shapes, or thin/delicate parts. EDM works by eroding metals using electrical sparks between an electrode tool and workpiece, allowing complex shapes to be machined. Laser beam machining uses a focused high-energy laser beam to drill, cut or mark materials. Waterjet machining directs a high-velocity water jet, sometimes with abrasives added, to cut through materials using the force of the water. These advanced processes enable machining of materials and shapes not possible through traditional methods.