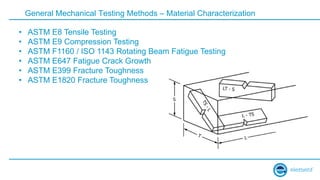

The document outlines mechanical testing methods for additive manufactured medical devices, focusing on the evaluation of materials, processes, and standards necessary for compliance with regulatory requirements. It highlights common pitfalls in protocol development, including issues with specimen preparation and acceptance criteria, while providing specific guidance on tests such as tensile, fatigue, and abrasion. Recommendations emphasize the importance of thorough testing and adherence to established standards to ensure the performance and safety of medical devices made through additive manufacturing.