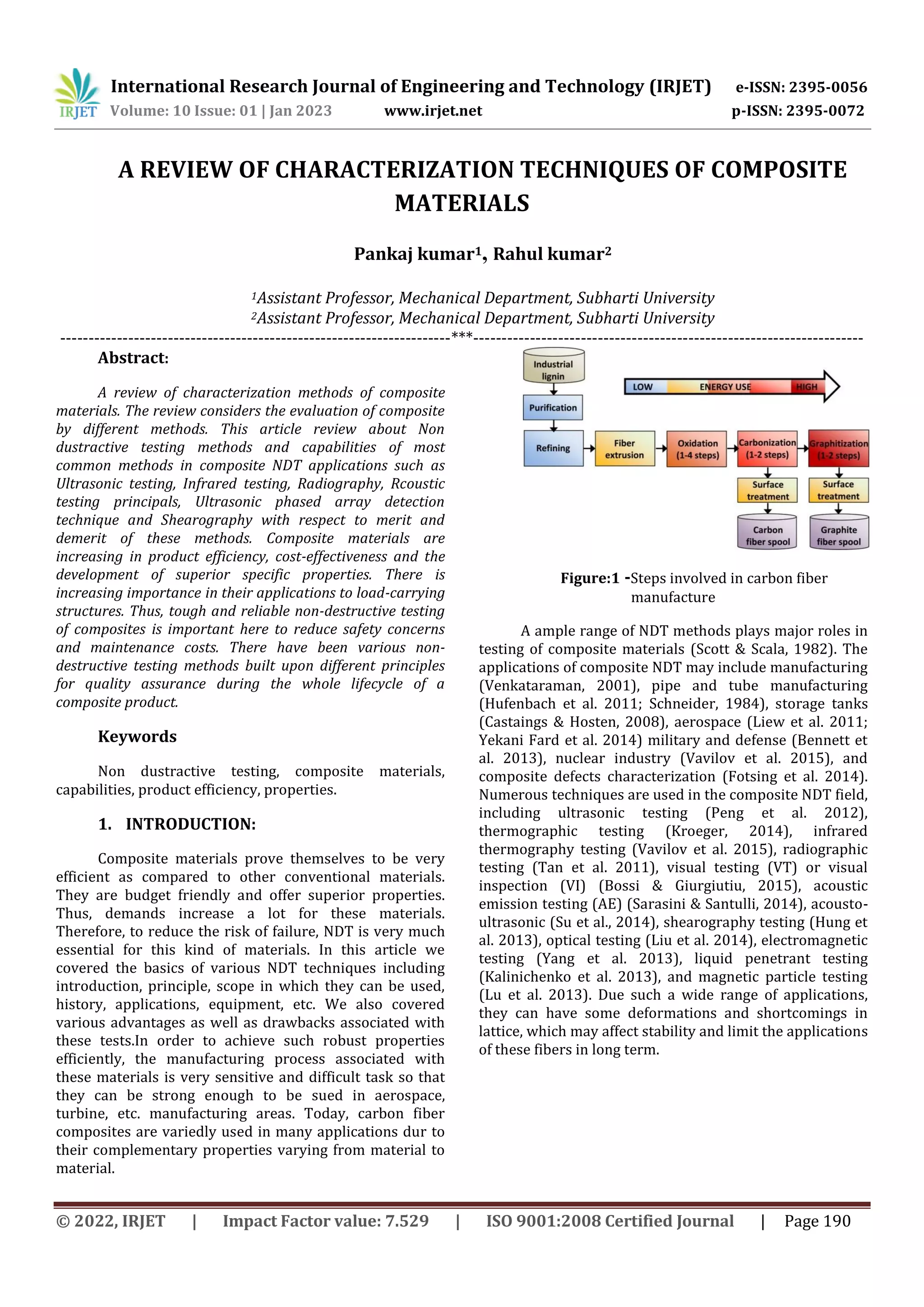

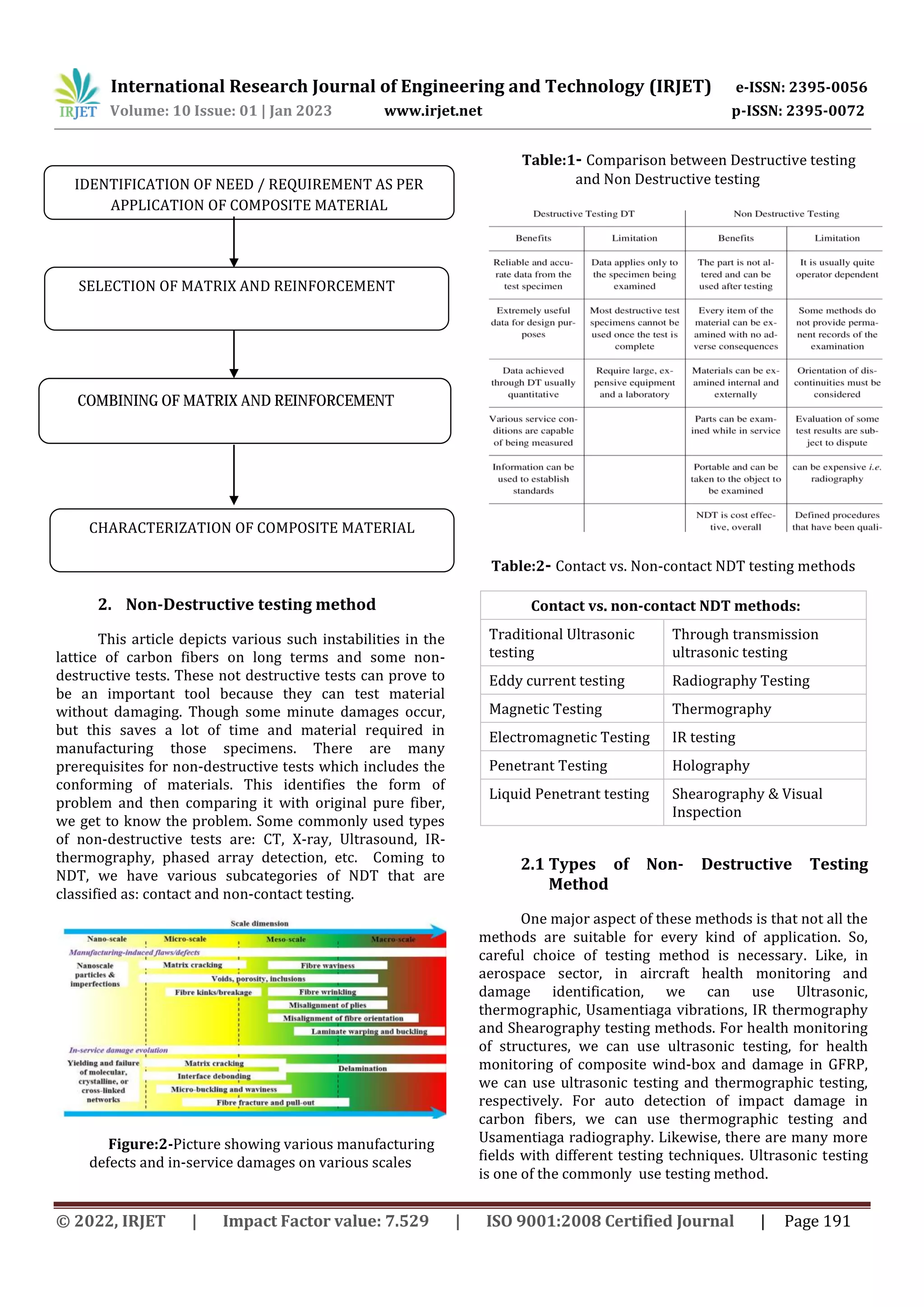

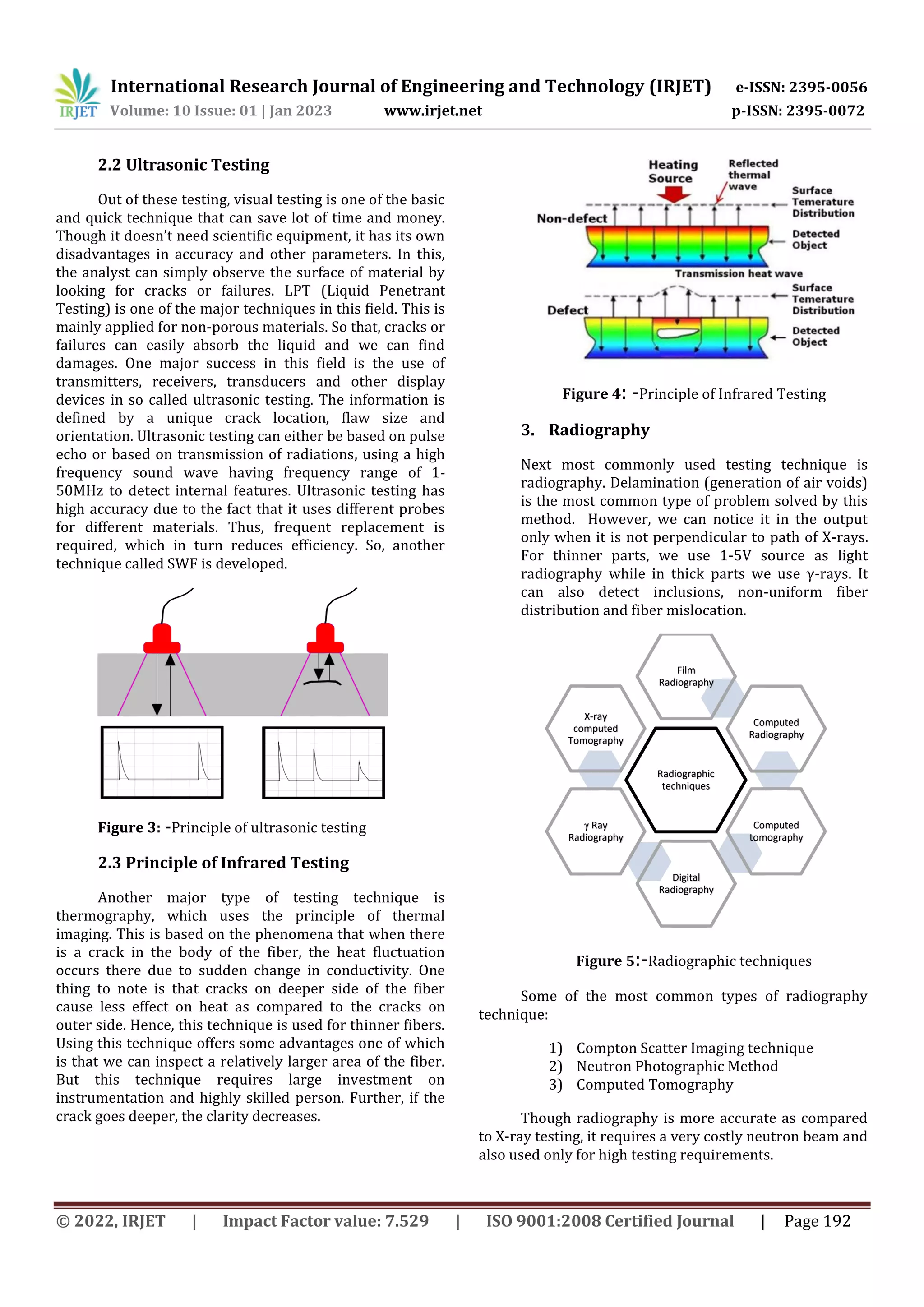

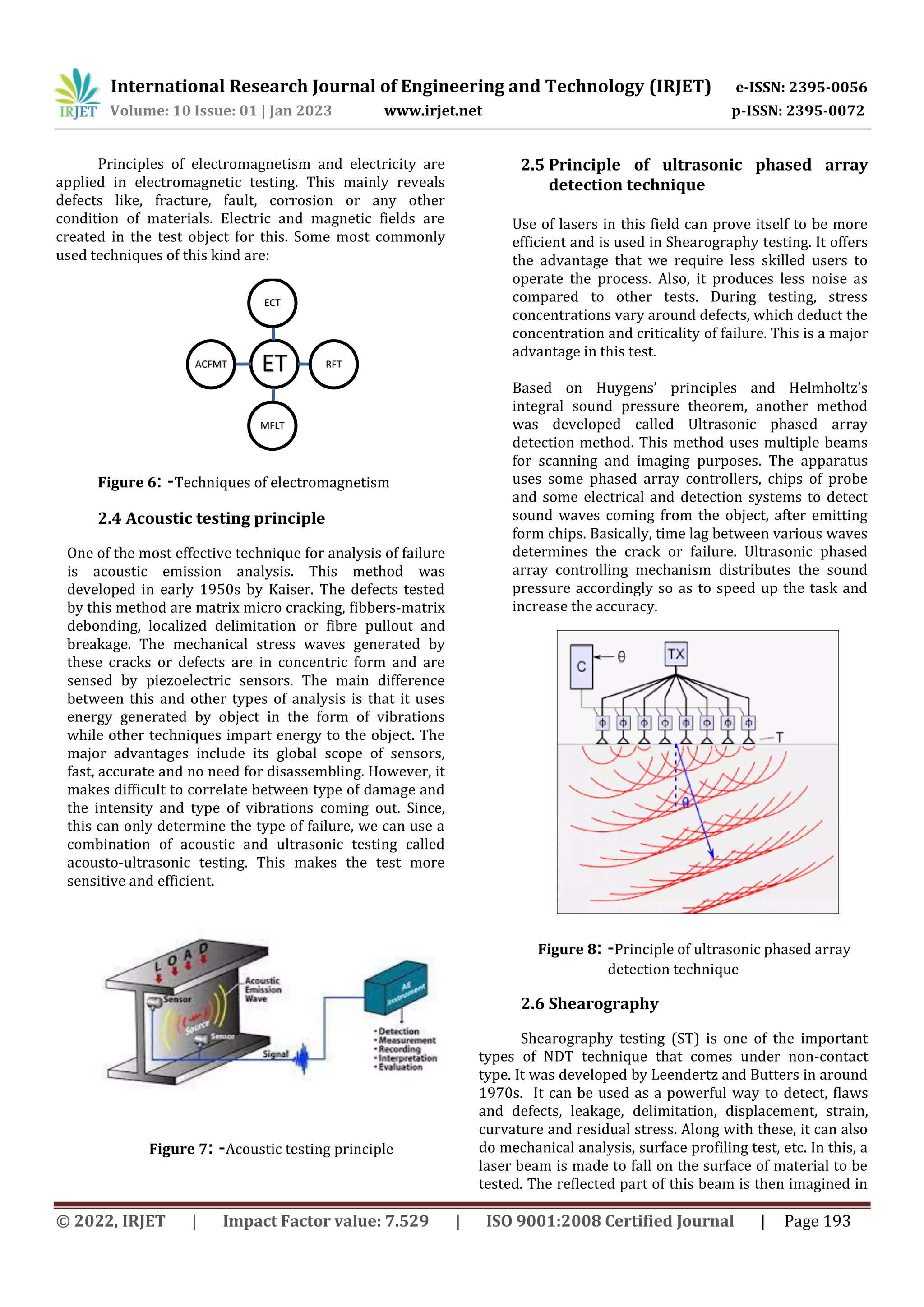

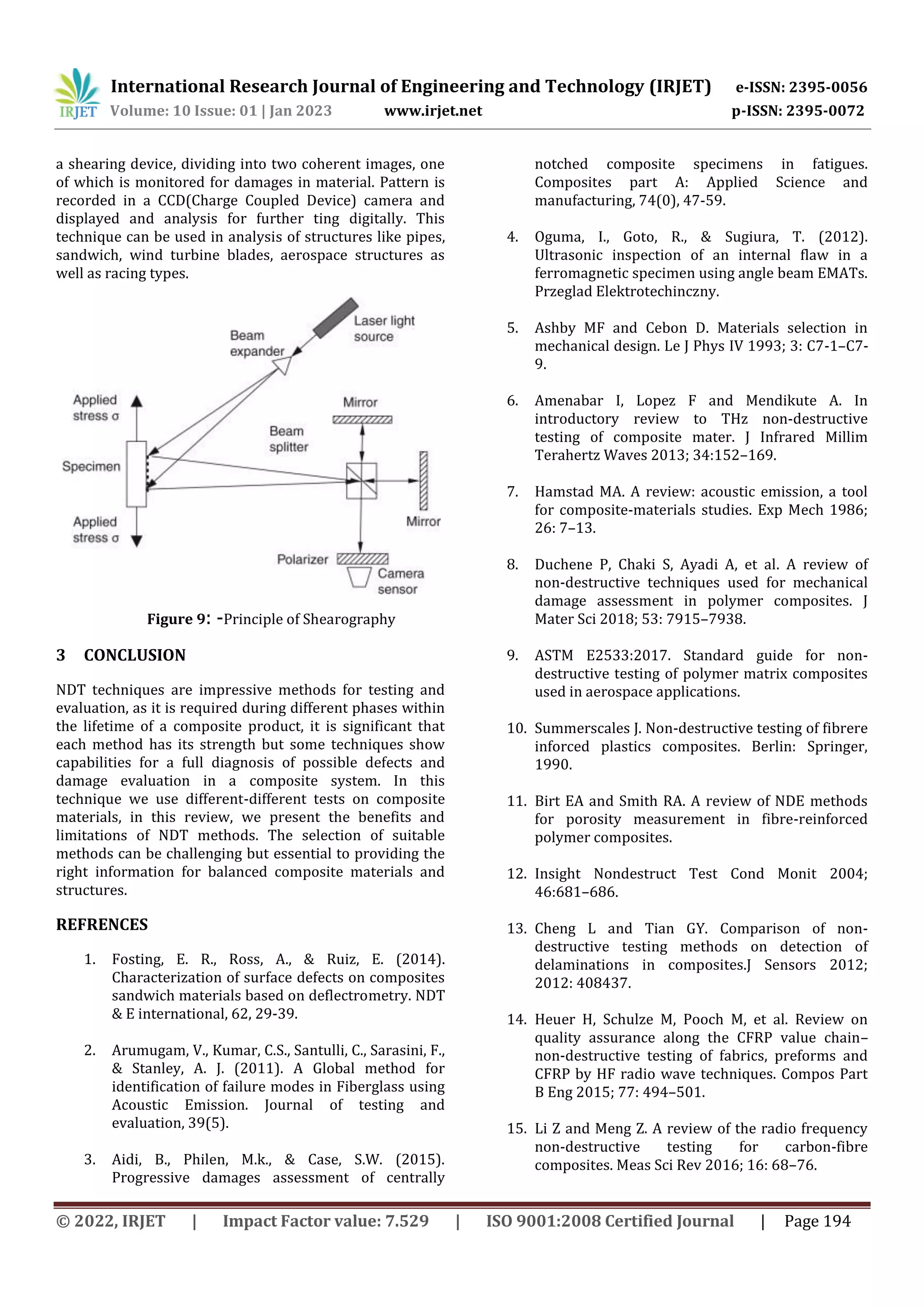

This document reviews various non-destructive testing techniques for characterizing composite materials. It discusses techniques such as ultrasonic testing, infrared testing, radiography, acoustic emission testing, and shearography. For each technique it explains the basic principles, capabilities, advantages, and limitations. The review finds that no single technique can fully diagnose all potential defects, so careful selection of the appropriate method is important depending on the application and type of information needed. Non-destructive testing is a significant part of evaluating composites throughout their lifetime to ensure safety and performance.