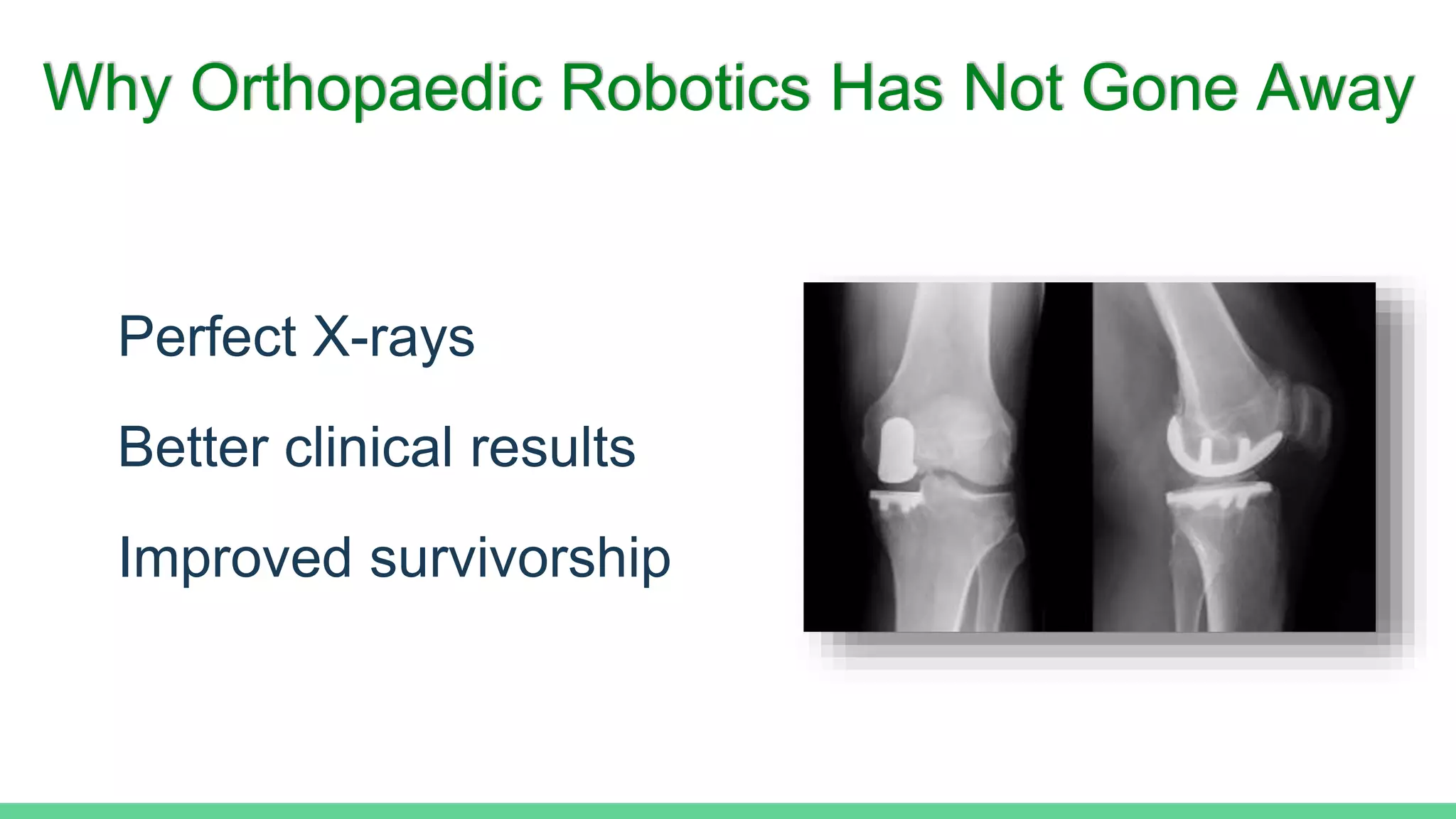

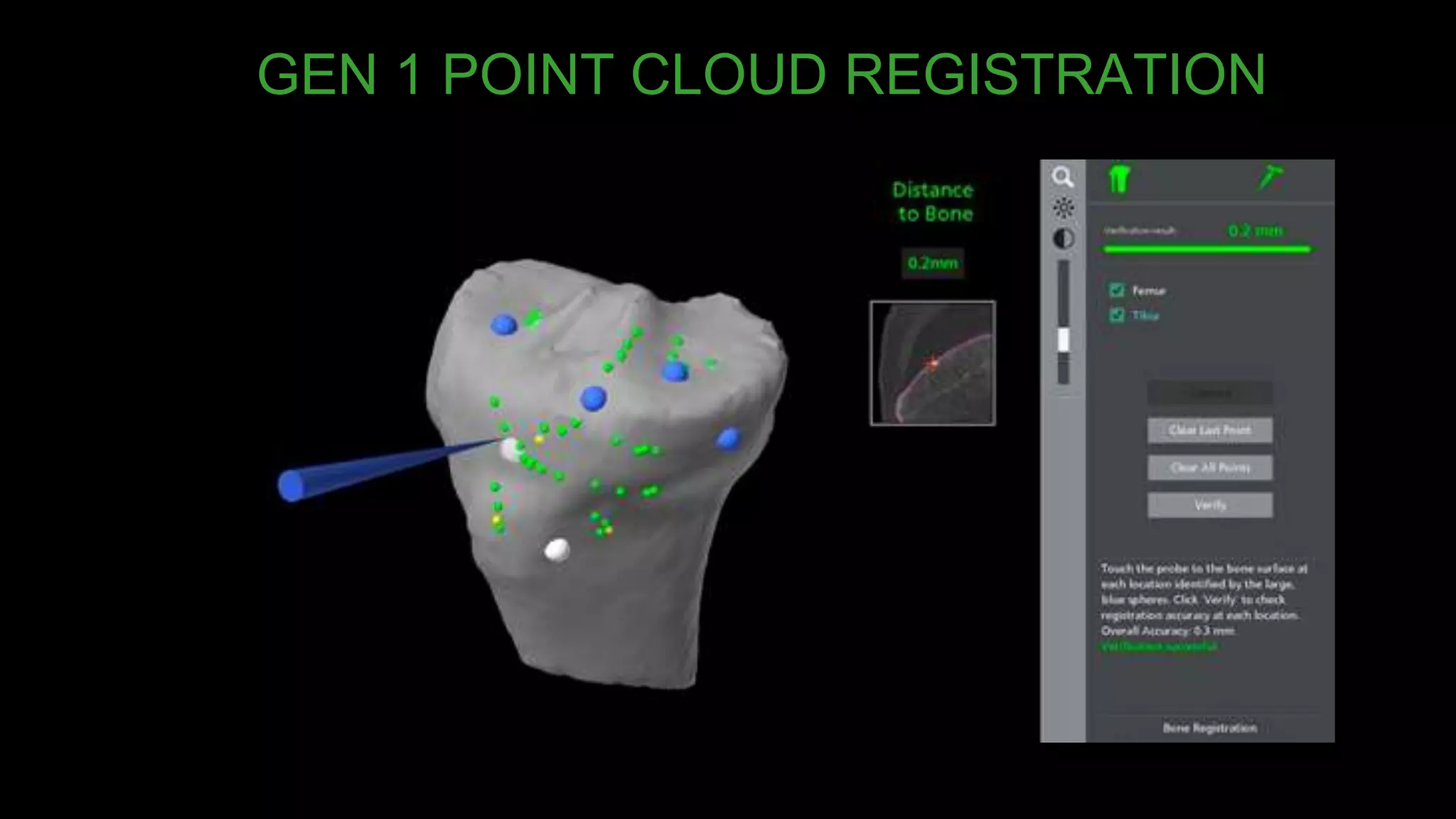

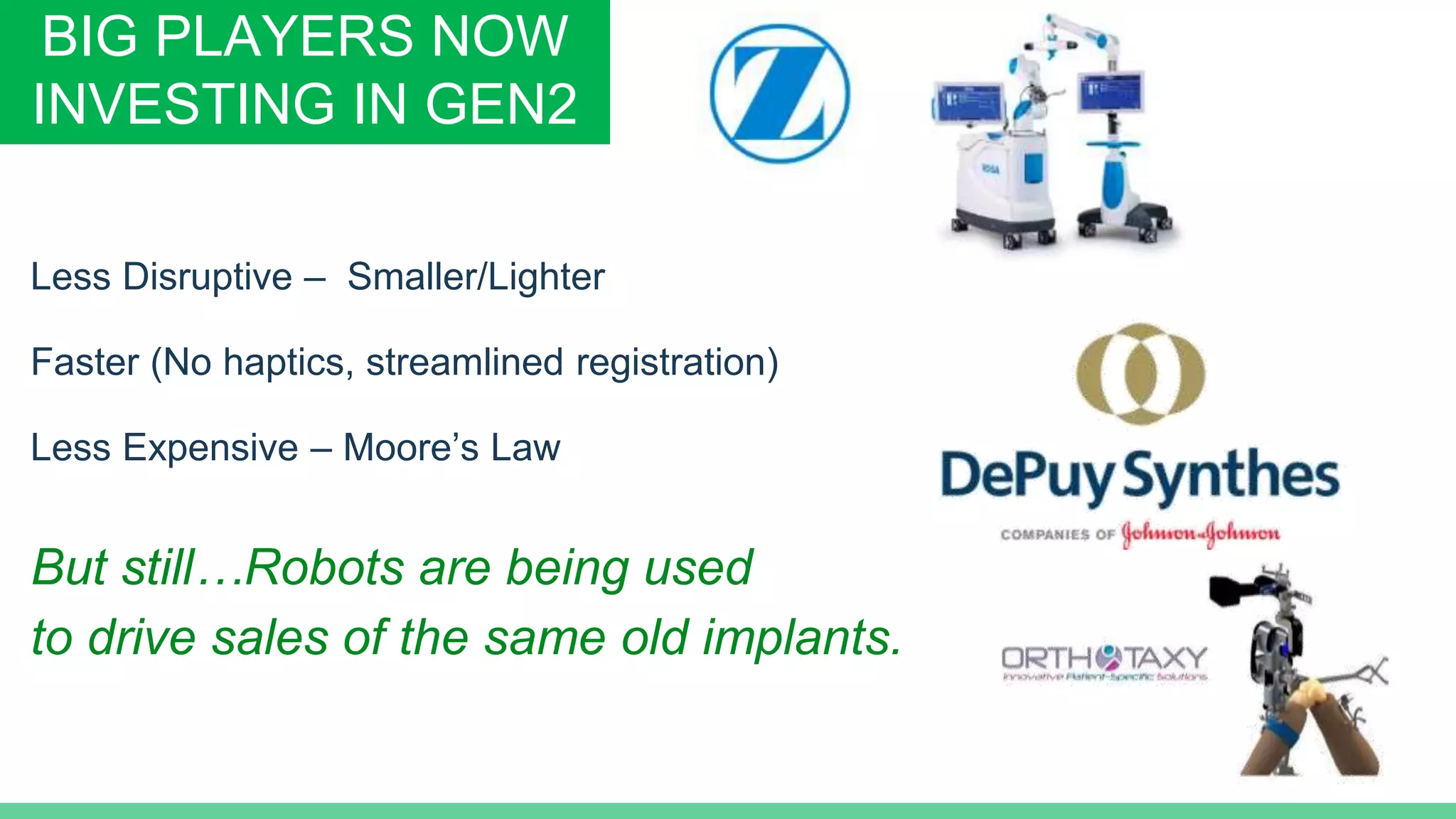

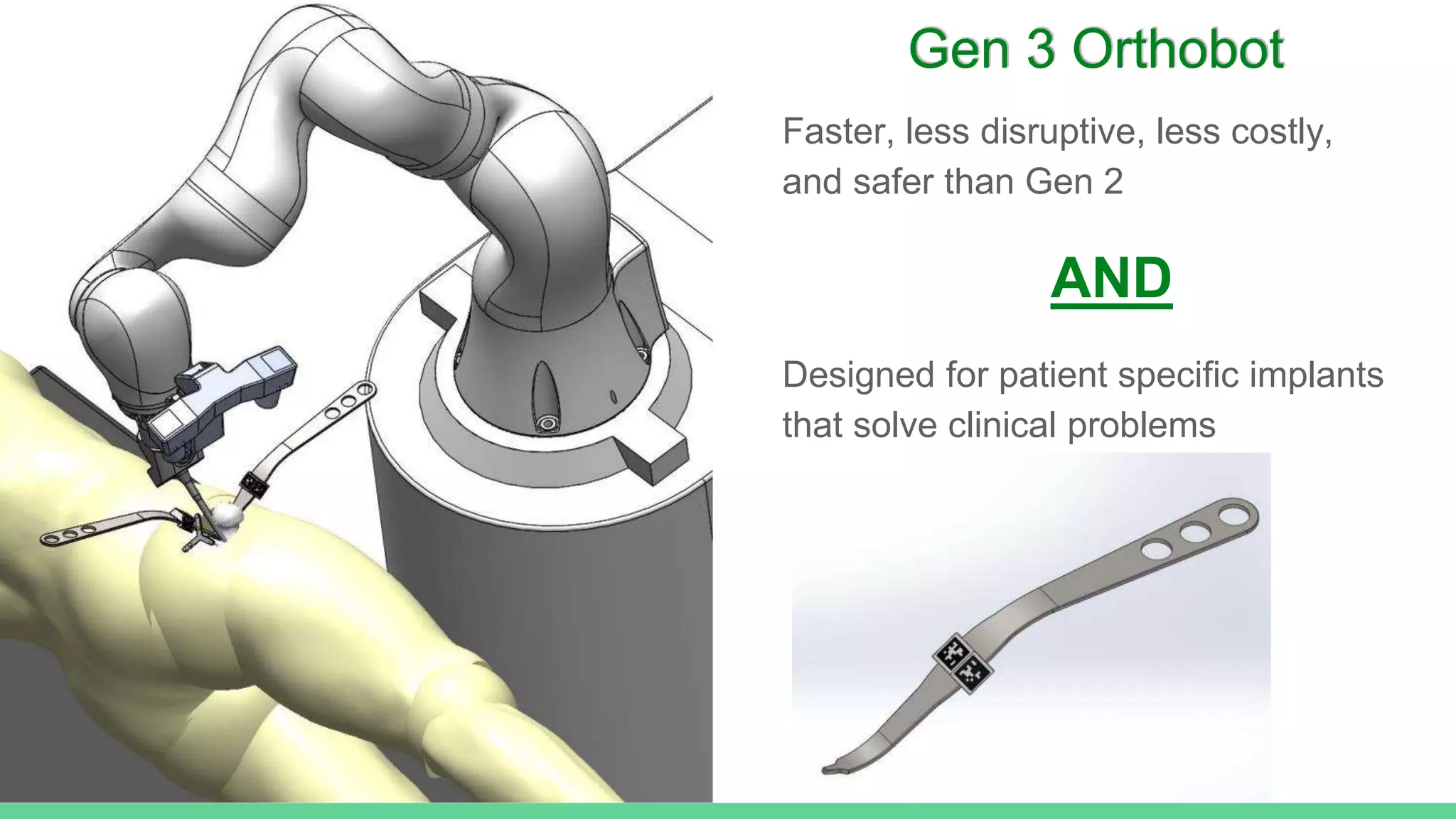

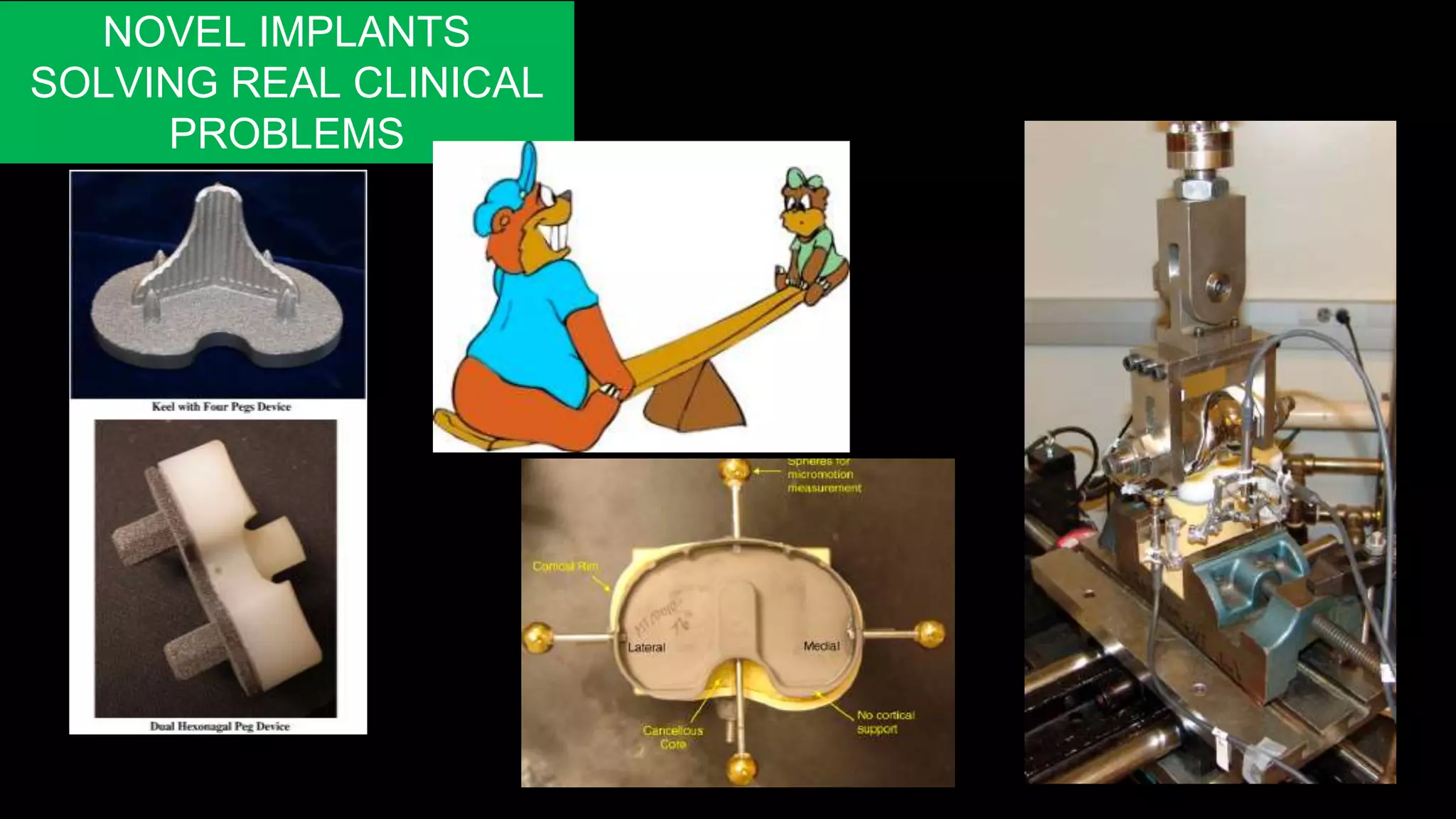

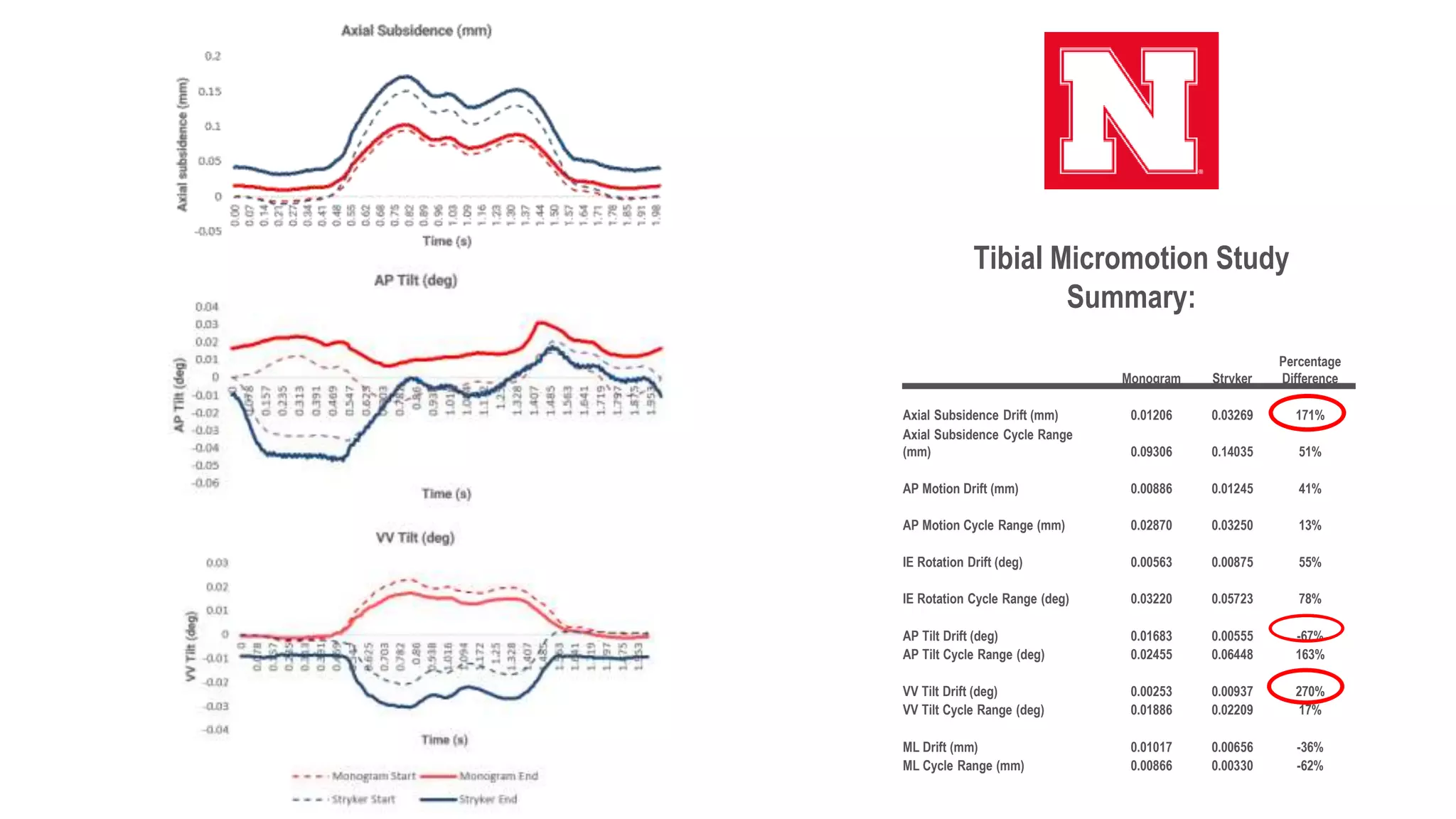

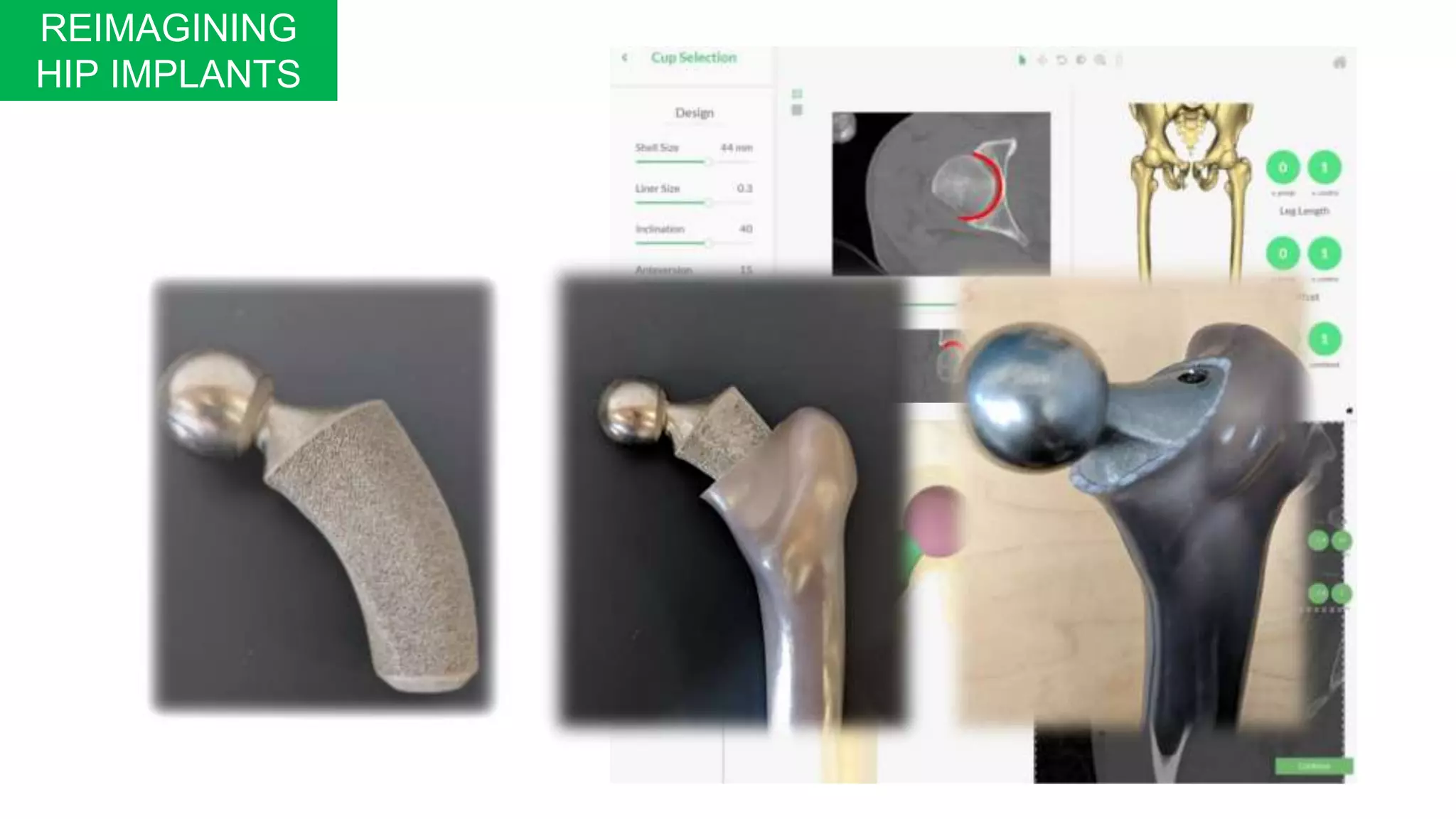

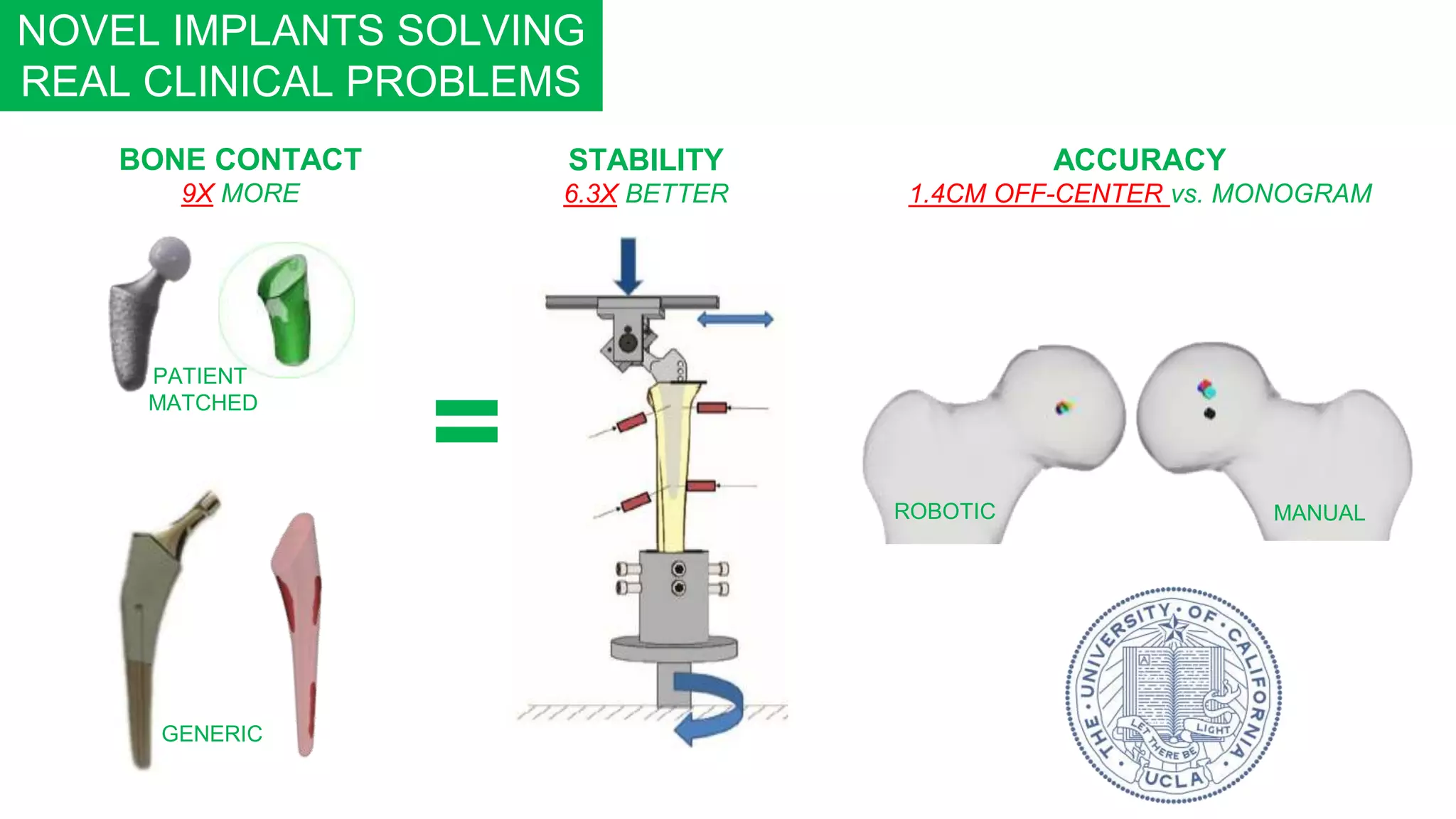

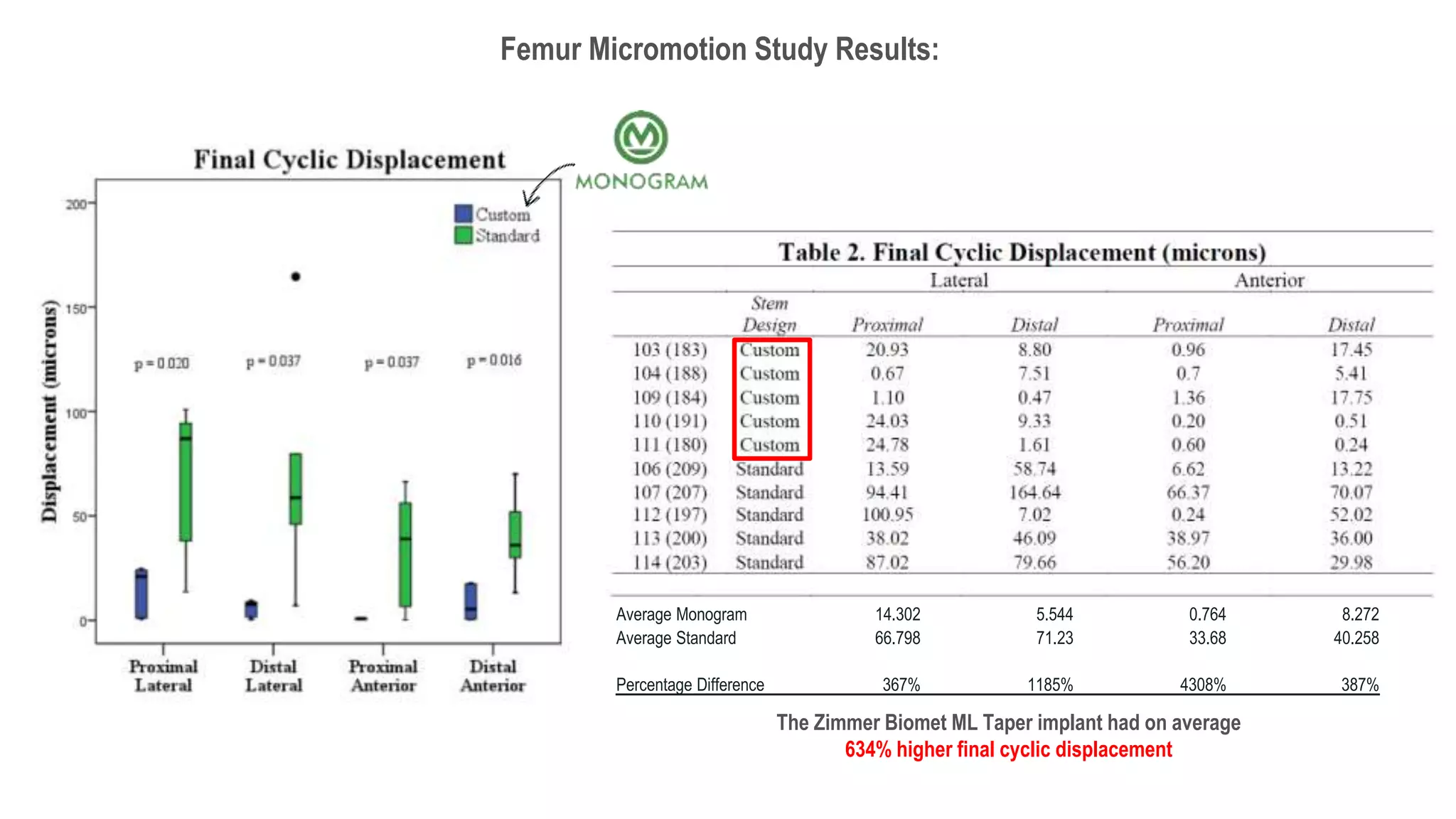

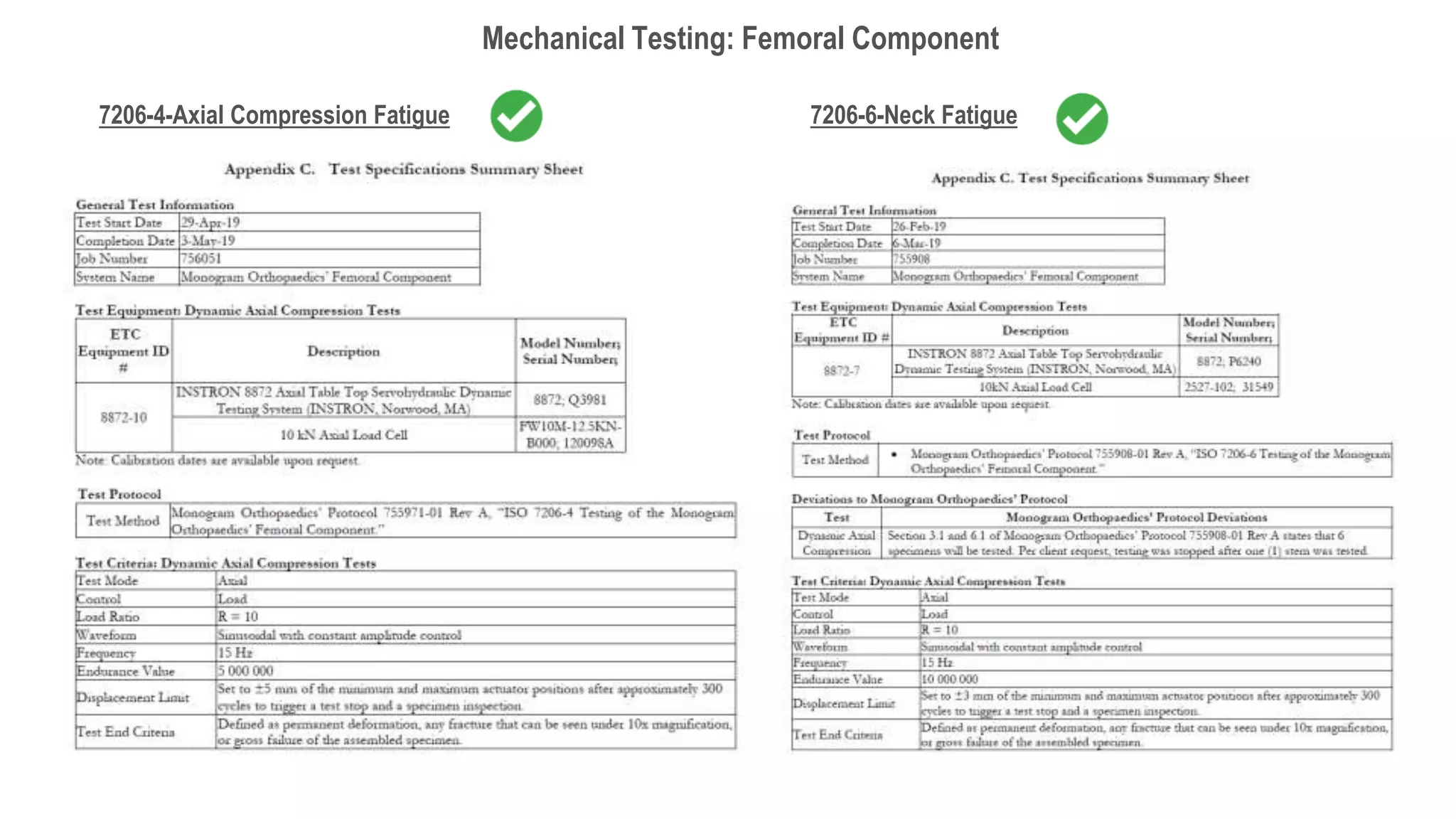

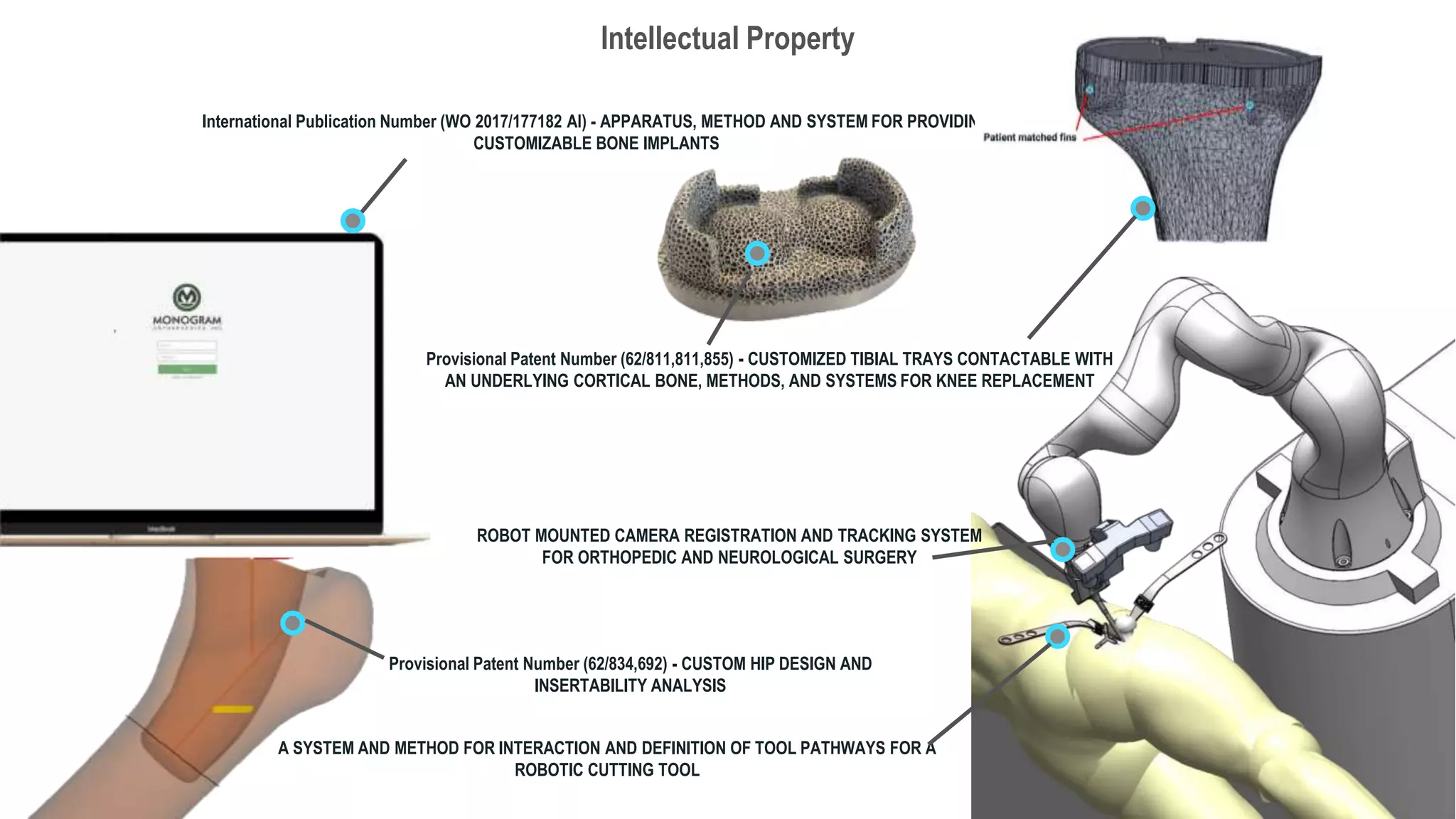

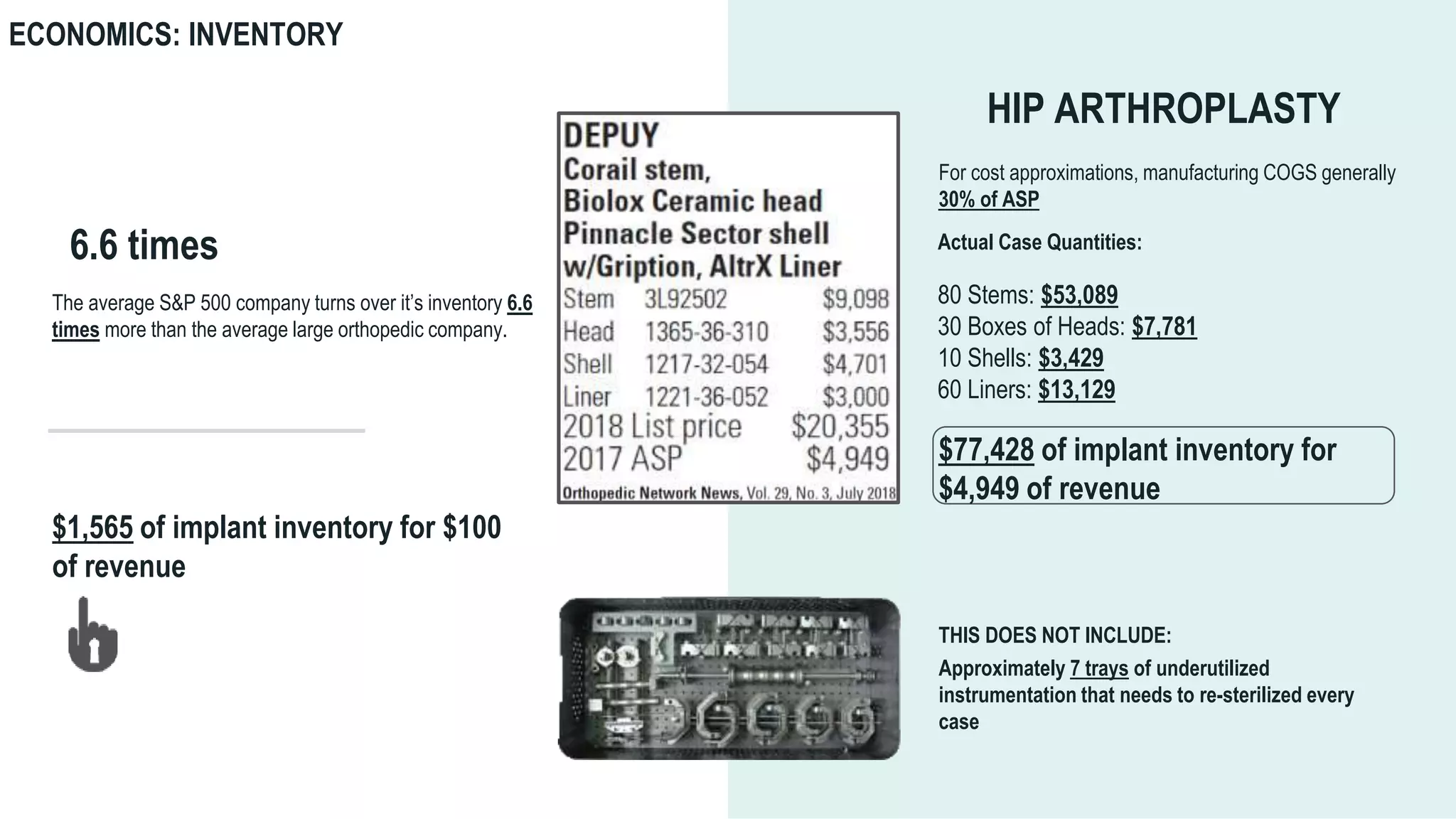

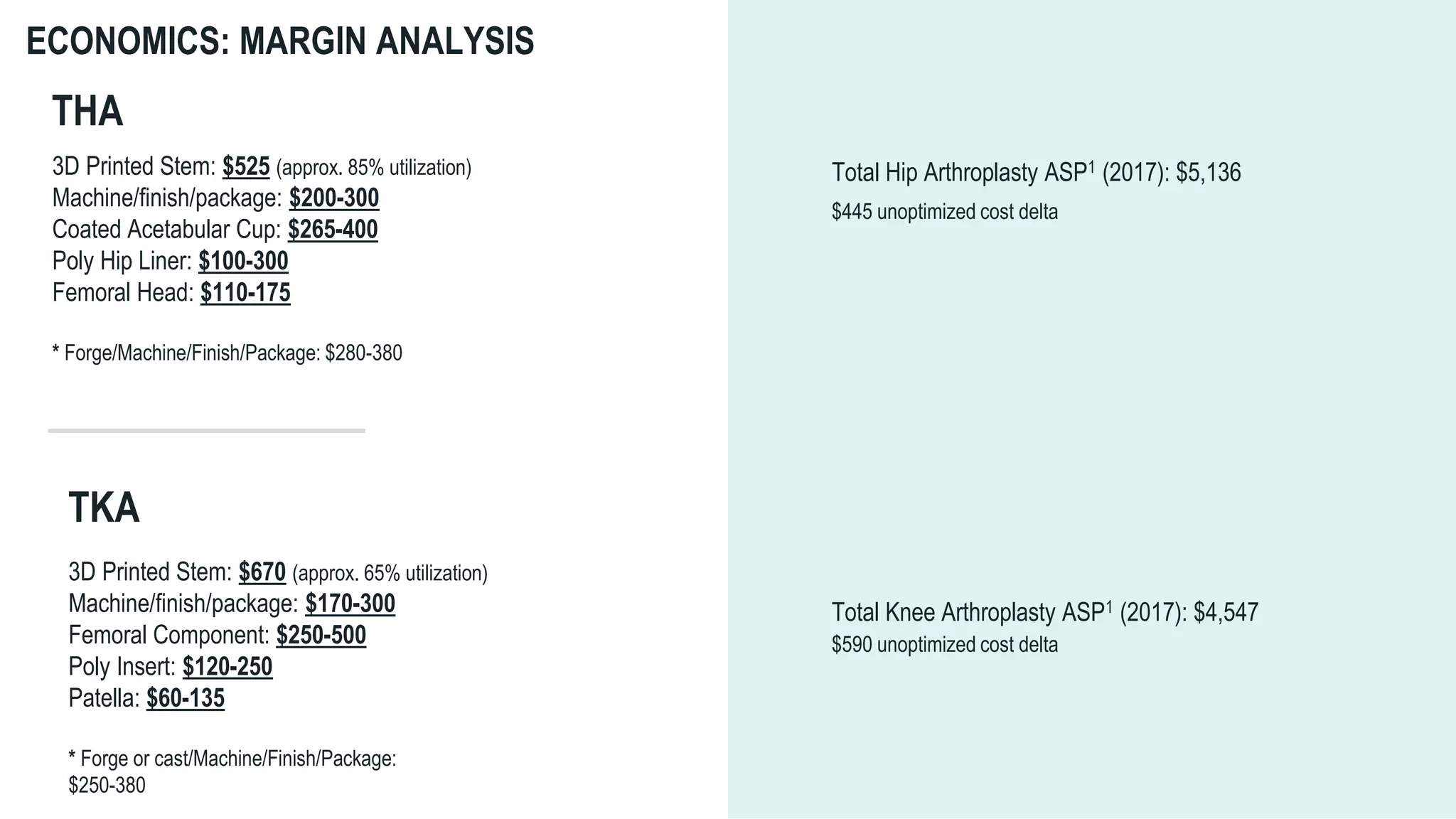

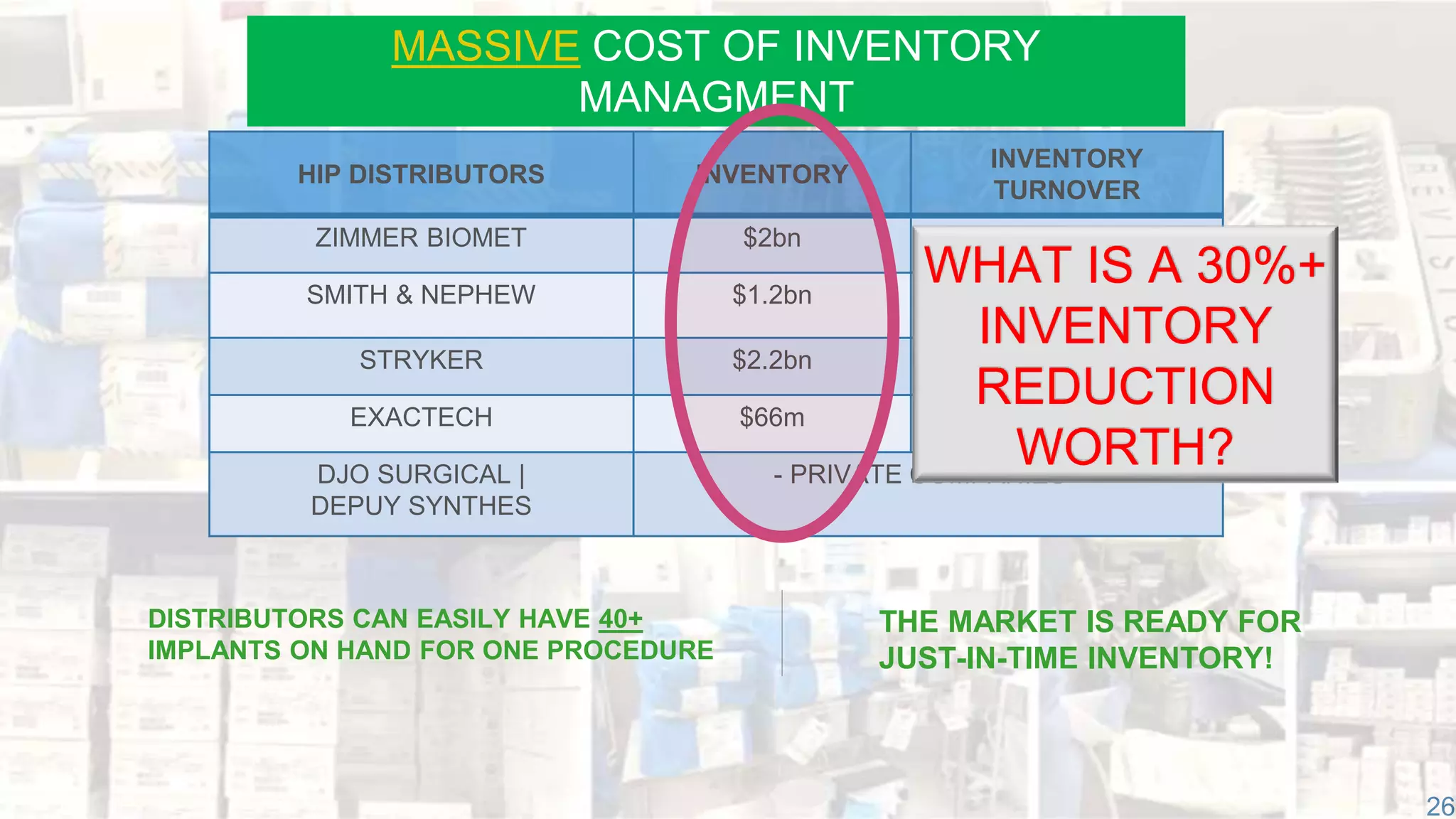

The document discusses the advancements in orthopaedic robotics, emphasizing the shift from Gen 1 to Gen 2 and Gen 3 robots that are faster, less disruptive, and more cost-effective. It presents data on the improved performance of novel implants and the potential for customized solutions in knee and hip surgery to solve clinical problems effectively. Additionally, the document highlights economic implications, including inventory management challenges and the potential benefits of just-in-time inventory systems in the orthopaedic industry.