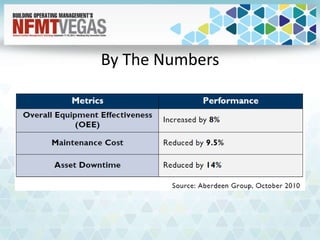

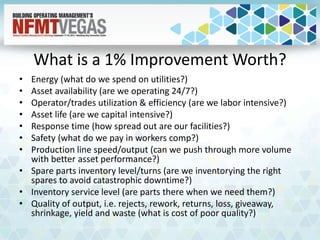

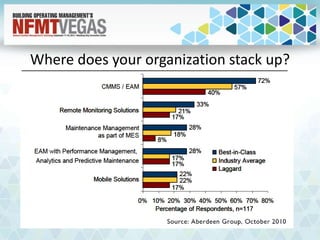

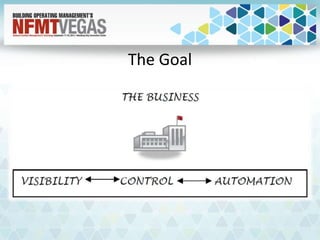

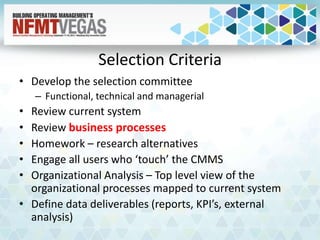

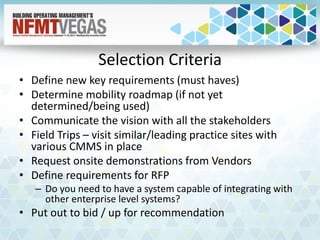

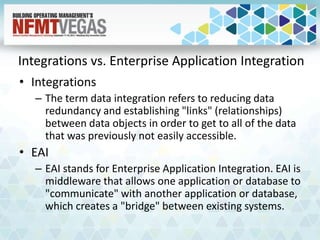

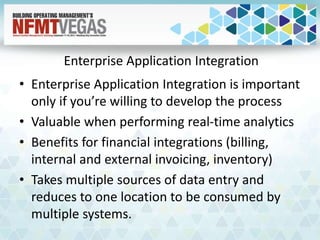

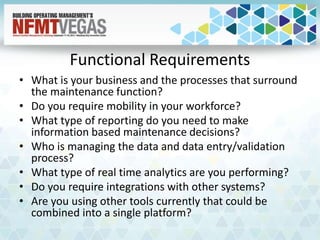

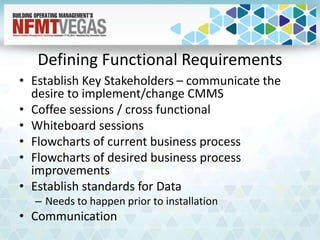

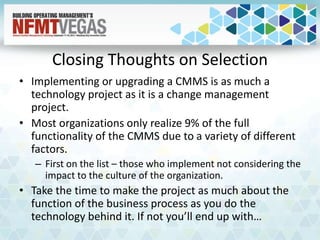

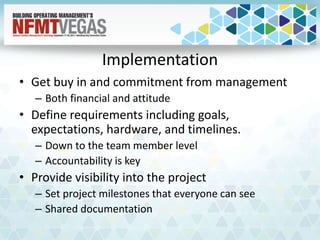

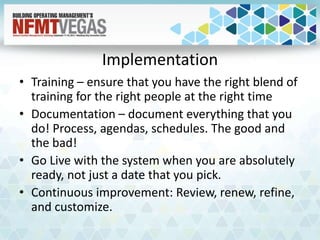

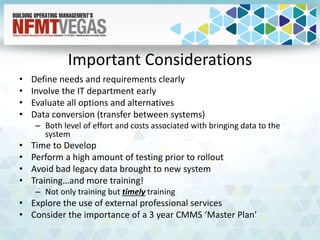

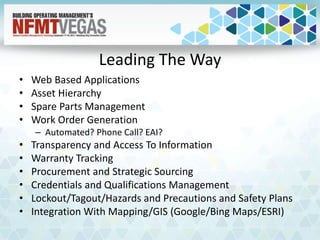

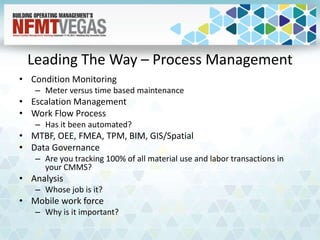

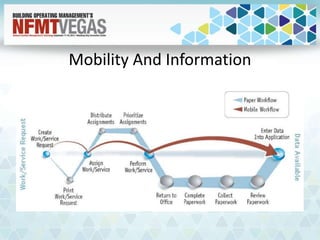

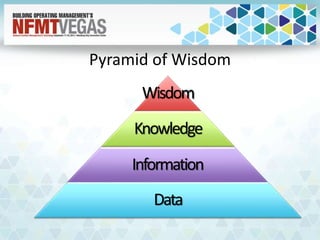

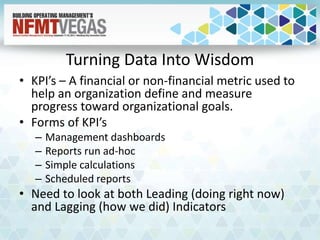

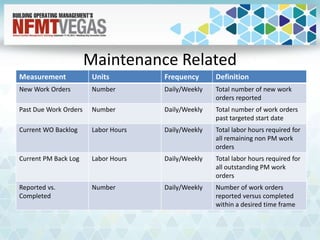

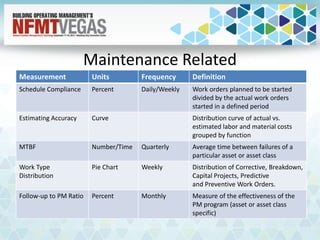

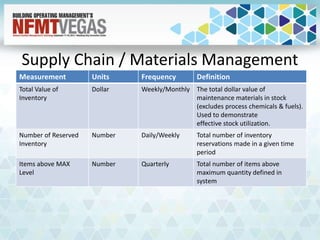

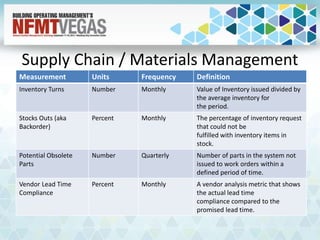

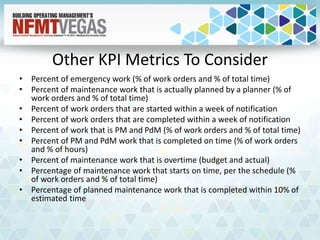

This document discusses leveraging a computerized maintenance management system (CMMS) from selection through daily use. It begins by outlining the business benefits of a 1% improvement in key maintenance metrics. Selection criteria for a CMMS include defining requirements, benchmarking current performance, and selecting a system that integrates with other applications. Proper implementation requires training, documentation, and continuous improvement. Leading practices involve mobile and analytical capabilities to turn maintenance data into actionable insights. Key performance indicators allow measuring progress toward maintenance goals.