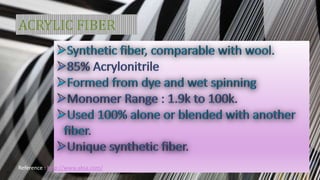

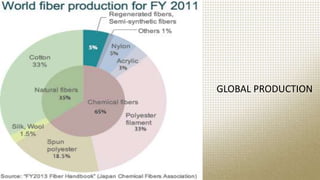

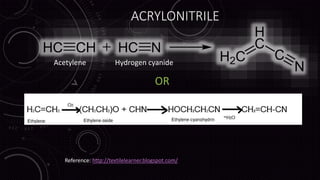

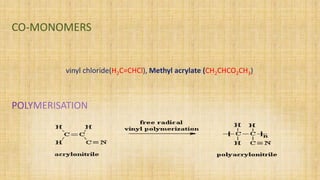

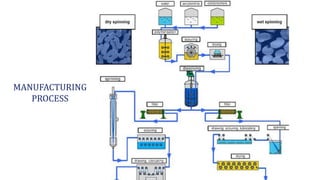

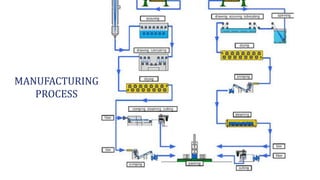

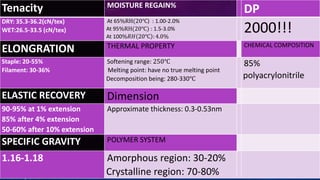

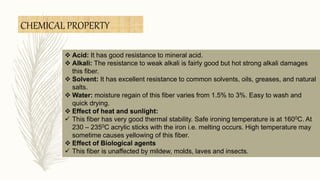

Acrylic fiber was first created by DuPont in 1941 under the trade name Orlon. It began large scale production in the 1950s. Acrylic fiber is made from acrylonitrile monomer which is derived from acetylene and hydrogen cyanide. The monomer undergoes polymerization with co-monomers like vinyl chloride or methyl acrylate. The manufacturing process involves the polymerization of acrylonitrile followed by extrusion to form fibers. Acrylic fiber has good elastic recovery, is resistant to chemicals and sunlight, retains warmth well and is easy to dye. It is used for clothing, home furnishings, industrial applications, and other uses.

![End use

• [FOR CLOTHING]

Sweaters,Women's and Children'sWear, Sports Wear, Socks,

Knitted Underwear, Pajamas, Gloves, etc

• [FOR HOME FURNISHINGS AND BEDDING]

Carpets, AVariety of Rugs, Upholstery, Cushions, Blankets,

Pile Sheets, etc.

• [FOR INDUSTRIAL USES]

Felts for Paper Making, Filter Cloth, AlternativeAsbestos,

Tents, Sheet, etc.

• [FOR OTHER USES]

Rag Doll,Toys, AuxiliaryTapes for Bags, Braids, Cloth for Bags,](https://image.slidesharecdn.com/acrylic-160829103439/85/Acrylic-Fiber-15-320.jpg)