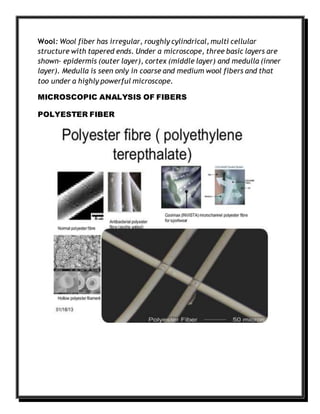

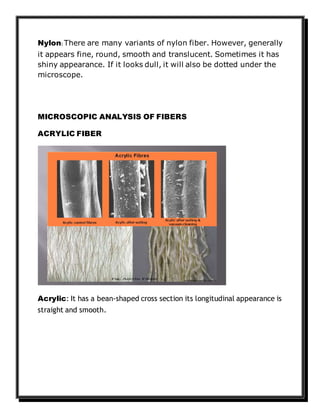

This document provides information on identifying natural and man-made fibers through various tests. It discusses burn tests that examine how fibers behave when exposed to flame, as well as solubility tests that observe how fibers react to different chemicals. Specific fibers like silk, wool, cotton, nylon, acrylic, polyester, polypropylene, and linen are examined under a microscope to view their distinguishing microscopic characteristics. The document also provides methods to distinguish certain fibers from one another, such as using hydrochloric acid to dissolve silk but cause wool to swell.