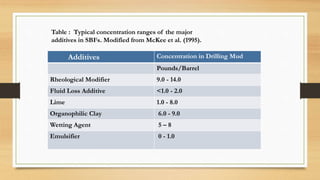

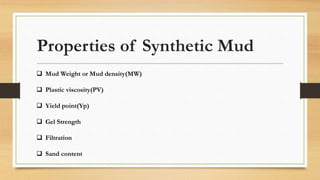

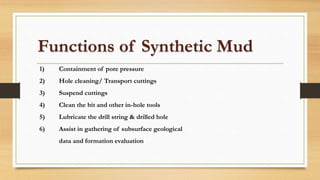

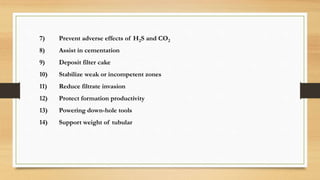

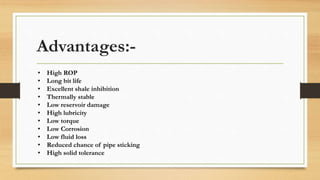

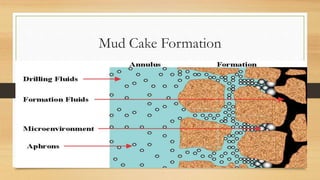

The document discusses synthetic muds used in drilling fluids, detailing their compositions, types, and properties. It categorizes synthetic muds into four types: synthetic hydrocarbons, ethers, acetals, and esters, and outlines their components and functions. Additionally, it highlights the advantages and disadvantages of synthetic muds, emphasizing their low toxicity and environmental benefits compared to traditional drilling fluids.